What is flowability?

2023-02-22WIKI

Flowability is used to describe the flow properties of the powder under gravity. The flowability can be simply evaluated using only one parameter, such as the angle of repose, the compressibility, or the angle of spatula. However, flowability is a property related to various indices, which can be expressed more rigorously as the weighted sum of many parameters associated with powder characterization.

Carr indices method based on the angle of repose, the compressibility, the angle of spatula, uniformity, and cohesion is a more comprehensive method to evaluate the powder flowability. Uniformity can be calculated by dividing D60 by D10. Cohesion is determined by measuring the mass of powder on each sieve after the vibration of the sample for a specific period of time.

Carr Indices Chart of Flowability

|

Angle of Repose |

Compressibility |

Angle of Spatula |

Uniformity* |

Cohesion* |

|||||||||||

|

Degree |

Index |

Valve |

Index |

Degree |

Index |

No. |

Index |

% |

Index |

||||||

|

≤25 26-29 30 31 32-34 35 36 37-39 40 41 42-44 45 46 47-54 55 56 57-64 65 66 67-89 90 |

25 24 22.5 22 21 20 19.5 18 17.5 17 16 15 14.5 12 10 9.5 7 5 4.5 2 0 |

≤5 6-9 10 11 12-14 15 16 17-19 20 21 22-24 25 26 27-30 31 32 33-36 37 38 39-45 ≥45 |

25 24 22.5 22 21 20 19.5 18 17.5 17 16 15 14.5 12 10 9.5 7 5 4.5 2 0 |

≤25 26-30 31 32 33-37 38 39 40-44 45 46 47-59 60 61 62-74 75 76 77-89 90 91 92-99 ≥99 |

25 24 22.5 22 21 20 19.5 18 17.5 17 16 15 14.5 12 10 9.5 7 5 4.5 2 0 |

1 2-4 5 6 7 8 9 10-11 12 13 14-16 17 18 19-21 22 23 24-26 27 28 29-35 ≥35 |

25 24 22.5 22 21 20 19.5 18 17.5 17 16 15 14.5 12 10 9.5 7 5 4.5 2 0 |

- - - - - - - - - - - ≤6 6-9 10-29 30 31 32-54 55 56 57-79 ≥79 |

- - - - - - - - - - - 15 14.5 12 10 9.5 7 5 4.5 2 0 |

||||||

|

Evaluation of Flowability |

|||||||||||||||

|

Degree |

Very Good |

Fairly Good |

Good |

Normal |

Not Good |

Bad |

Very Bad |

||||||||

|

Sum of Indices |

90-100 |

80-89 |

70-79 |

60-69 |

40-59 |

20-39 |

0-19 |

||||||||

* Determination of using uniformity or cohesion is based on mean bulk density and sieve diameter

of the powder sample.

Recommended articles

Related Particle Size Analyzer

-

PowderPro A1

Powder Characteristics Tester

Operation Mode: Automatic

Tapping Speed: 50 - 300 taps/min

Repeatability: ≤3% variation

-

BeDensi T Pro Series

Tapped Density Tester with a Wallet-Friendly Solution

Number of Workstations: 1-3

Tapping Speed: 100 - 300 taps/min

Repeatability: ≤1% variation

-

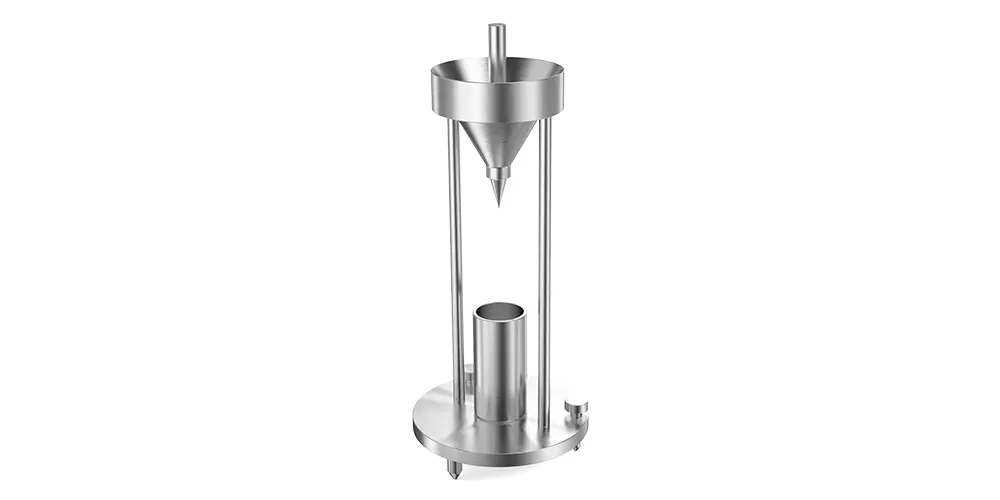

BeDensi B1

Bulk Density Tester

Measurement: Bulk Density(coarse powders)

Compliance with GB/T 16913

-

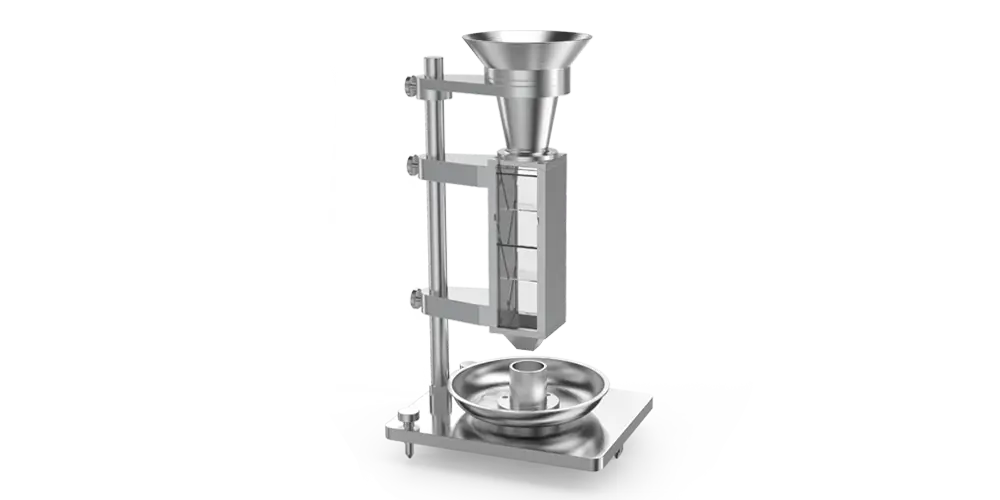

BeDensi B1-S

Scott Volumeter

Measurement: Bulk Density

Compliance with USP, Ph. Eur., ASTM, and ISO standards

-

BeDensi P

Bulk Density Tester - Plastic

Measurement: Bulk Density

Compliance with ISO and GB/T standards

-

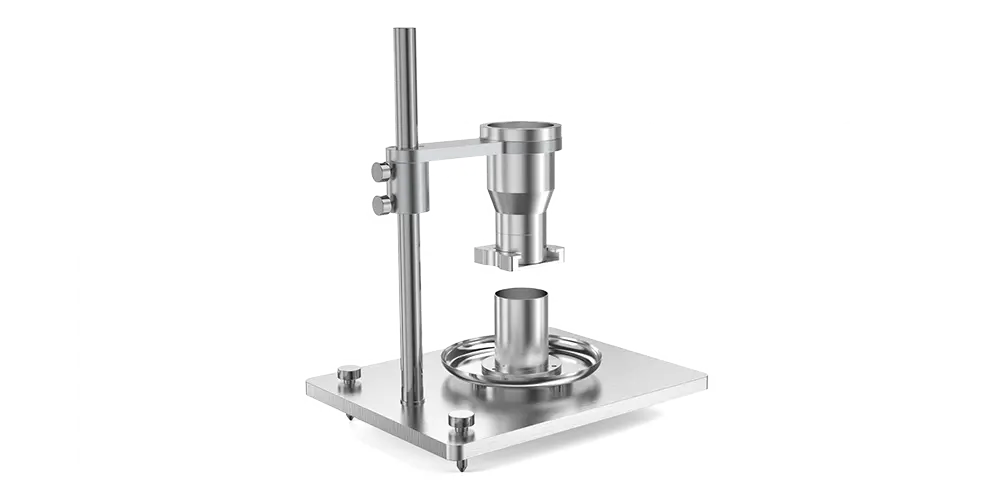

BeDensi AR

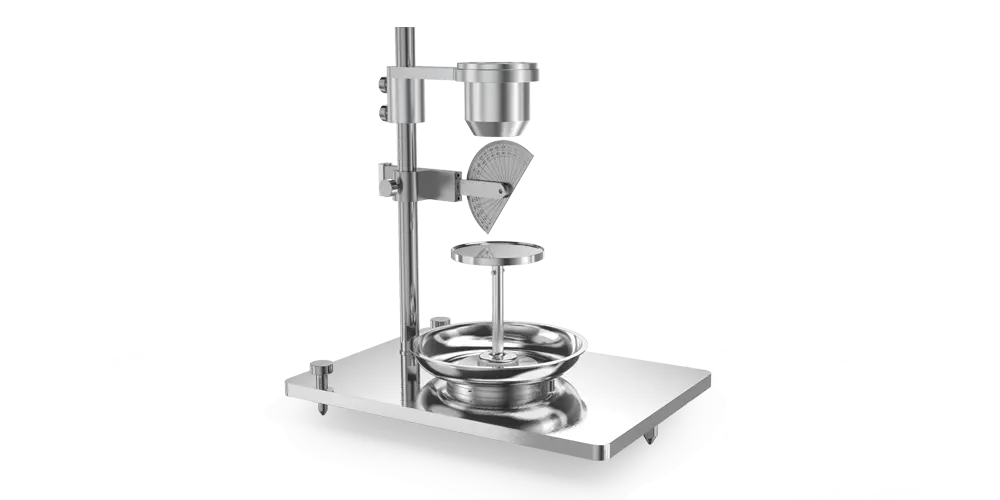

Angle of Repose Tester

Measurement: Angle of Repose

Compliance with USP and Ph. Eur. standards

-

BetterPyc 380

Automatic Gas Pycnometer

Technology: Gas Displacement Method

Temperature Range: 10 - 65 ℃

Resolution: 0.0001 g/cm³