- ● Introduction

- ● Particle size and shape analyzer

- ● Merits

- ● Measurement principle

- ● Application

- ● Supplementary Information

Introduction

Accurate measurement of particle size and shape is important for real-world product applications as it influences both manufacturing process and product quality. Image analysis has a significant advantage over other methods, such as static light scattering, sedimentation, or sieving, in that it can quickly analyze each particle image to determine its size and shape. When using the static image analysis method (SIA), particles are placed on a carrier and remain stationary in relation to the camera.

Particle size and shape analyzer

BeVision M1

Automated Static Image Analyzer

Dispersion type: Dry

Measurement range: 1 - 10,000μm

Technology: Automated Static Image Analysis

BeVision S1

Classical and Versatile Static Image Analyzer

Dispersion type: Dry & Wet

Measurement range: 1 - 3,000μm

Technology: Static Image Analysis

Merits

Since the sample remains static during the capturing process, high image quality and rich details are assured. With its high accuracy and repeatability, SIA is particularly well suited for characterizing small particles with narrow distribution. The following characterizes SIA:

1. High-resolution and clear images of particles

2. Undersized particle sensitivity

3. Small sample volume or weight

Measurement principle

4 steps to determining the particle shape and size by SIA:

1. Image taking

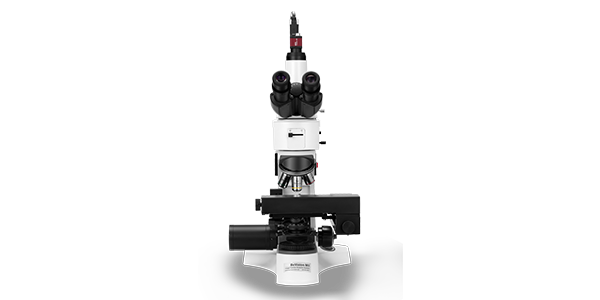

To get clear images, special digital cameras are used typically in conjunction with a microscope. The particles are present in a neutral state (e.g., on an objective), and they can be dispersed (separated) both in a dry mode (e.g., by simply conveying and riddling or by using compressed air) and a wet mode in a solvent.

2. Image processing and particles identification

Appropriate software processing results in enhanced images, realizing the elimination of isolated pixels and edging particles, the retouching of variations in brightness and signal noise, and the separation of agglomerated particles.

3. Particles size and shape parameters calculation

Size and shape parameters of every single particle will be calculated with the software.

4. Data statistics and classification

The particles are classified based on their size and shape parameters.

Application

SIA generates images of the fine particles with high resolution and clarity. Therefore, it is especially well suited for minerals, batteries, electronics, and pharmaceutical applications, where statistical data on particle shape and size can further differentiate materials in use.