BeDensi B1

The BeDensi B1 stands as a specialized bulk density tester crafted for assessing the bulk density of samples beyond metal powders. Employing the natural deposition method, it adheres to the standards outlined in GB/T 16913-4.3: Methods of dust character test-Determination of bulk density. Widely utilized in diverse sectors such as food, industrial chemistry, energy battery powder, research institutions, and quality inspection organizations, this tester offers valuable insights into the storage characteristics of powders, particularly within storage containers.

Features and Benefits

- ● Measurement: Bulk density

- ● Testing sample: Except for metal powders

- ● Technology: Natural deposition method

Overview

1. Measurement: Bulk Density

The BeDensi B1 stands as a specialized bulk density tester crafted for assessing the bulk density of samples beyond metal powders. Employing the natural deposition method, it adheres to the standards outlined in GB/T 16913-4.3: Methods of dust character test-Determination of bulk density. Widely utilized in diverse sectors such as food, industrial chemistry, energy battery powder, research institutions, and quality inspection organizations, this tester offers valuable insights into the storage characteristics of powders, particularly within storage containers.

2. Sample Preparation

The sample powder should be dried at 105°C for 4 hours, followed by natural cooling in the room, and then passed through an 80-mesh standard sieve to remove impurities.

For powders that undergo chemical reactions, melting, or sublimation at temperatures equal to or below 105°C, the drying temperature should be lowered by at least 5°C compared to the temperature at which these reactions occur, and the drying time should be appropriately extended.

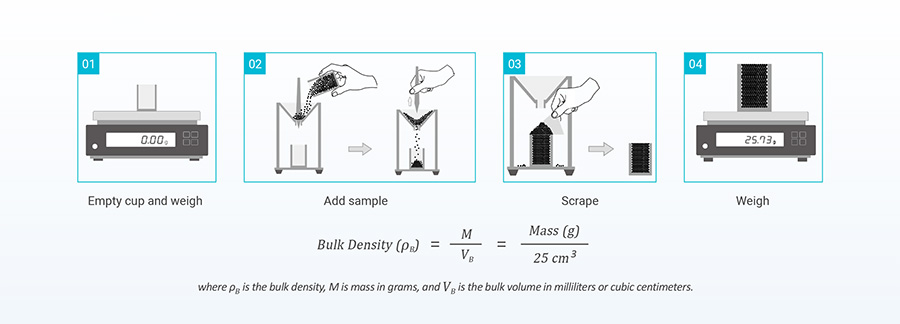

3. Measurement Procedure

- Bulk Density

4. Result Processing

The same sample should undergo three consecutive tests, and the average of these measurements is taken as the loose bulk density result for that sample. The difference between the maximum and minimum mass values obtained from these three tests should be less than 1 g. If not, additional tests should be conducted until the difference is less than 1 g. The average of three measurements that meet this criterion is then considered as the final determination result.

5. Application Example

Providing precision in bulk density measurement for different types of coffee samples.

The BeDensi B1 proves to be particularly effective in measuring the bulk density of coarse food powders that may be challenging for other funnel systems. In a comprehensive evaluation, various coffee samples undergo three cycles of measurement. This precision in measurement underscores the instrument's suitability for accurately assessing bulk density in scenarios where coarser powders are involved, providing valuable insights for quality control and process optimization in the food industry.

| Sample | Result (g/cm³) | ||||

| No.1 | No.2 | No.3 | Average | ||

| Coarse Grind Coffee |  |

0.3259 | 0.3224 | 0.3269 | 0.3251 |

| Fine Grind Coffee |  |

0.3490 | 0.3567 | 0.3501 | 0.3519 |

| Instant Coffee Powder |  |

0.4090 | 0.4064 | 0.4101 | 0.4085 |

Curated Resources

- GuidebookbigClick

Related Powder Characteristics Analyzer

-

BeDensi T Pro Series

Tapped Density Tester with a Wallet-Friendly Solution

Number of Workstations: 1-3

Tapping Speed: 100 - 300 taps/min

Repeatability: ≤1% variation

-

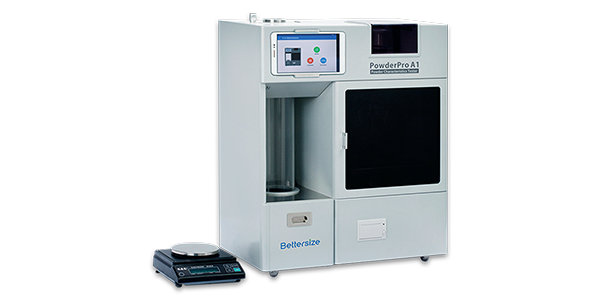

PowderPro A1

Automatic Powder Characteristics Tester

Operation Mode: Automatic

Tapping Speed: 50 - 300 taps/min

Repeatability: ≤3% variation

-

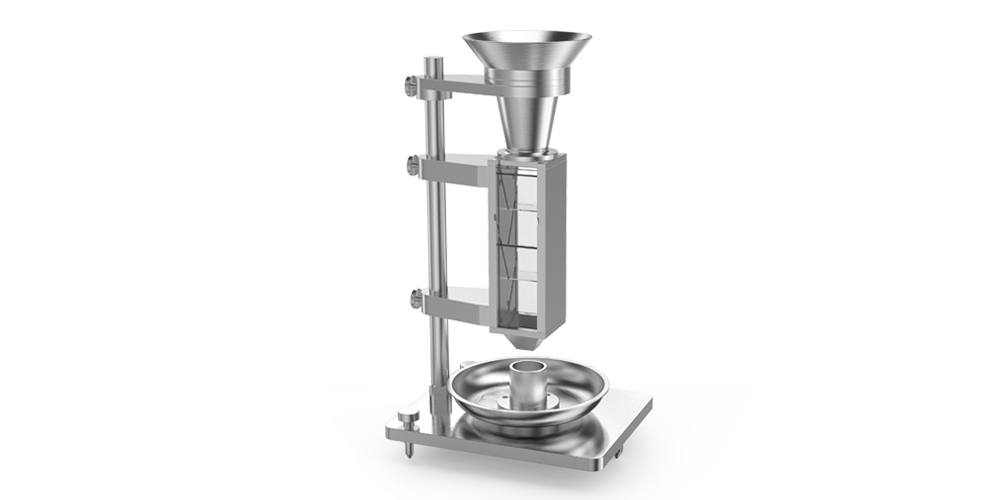

BeDensi B1-S

Scott Volumeter

Measurement: Bulk Density

Compliance with USP, Ph. Eur., ASTM, and ISO standards

-

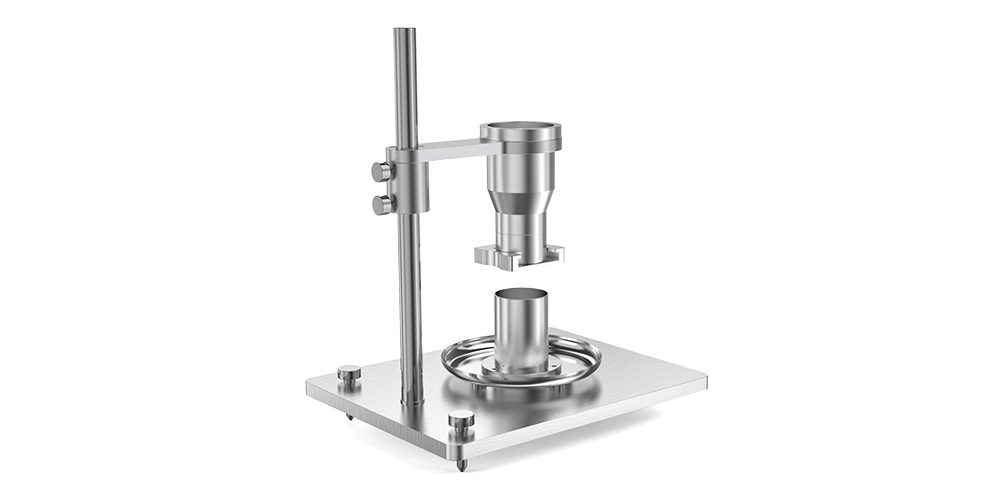

HFlow 1

Flowmeter Funnel

Measurement: Bulk density and Flow rate

Compliance with USP, Ph. Eur., ASTM, and ISO standards

-

BeDensi P

Bulk Density Tester - Plastic

Measurement: Bulk Density

Compliance with ISO and GB/T standards

-

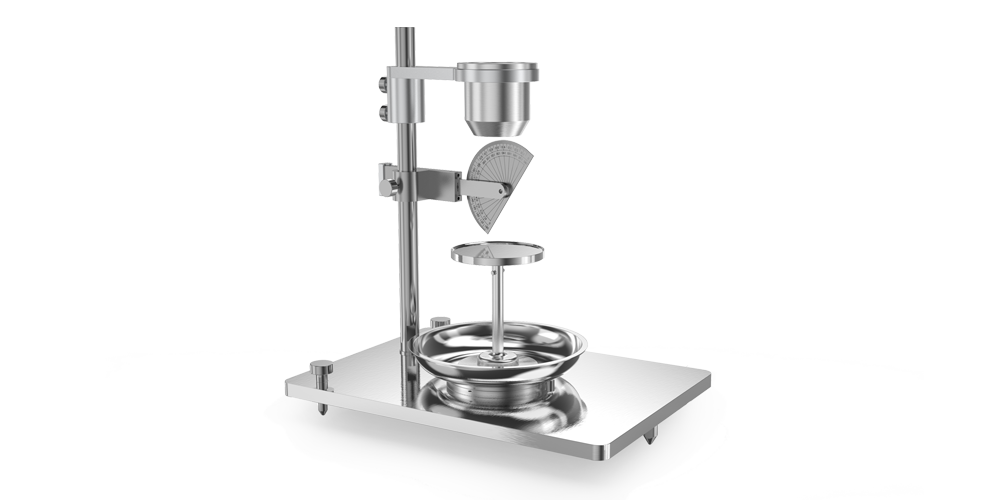

BeDensi AR

Angle of Repose Tester

Measurement: Angle of Repose

Compliance with USP and Ph. Eur. standards