Abrasives

Instruments provided by Bettersize offer the particle size distribution and particle shape analysis of silicon carbide, garnet, diamond, corundum, and aluminum oxide.

An abrasive is a material that reduces a surface by friction and rubbing. It thus finds itself put to good use in chemical mechanical polishing, DVR / CD discs, sandpaper, grinding wheels, cutting wheels, floor skid proofing, milling, toothpaste, kitchen, and bathroom cleaners.

As we can see abrasives are widely used and it is the "teeth" of the manufacturing industry. Silicon carbide powder is a type of milling material mainly used for multi-wire cutting machines, and its particle shape and particle size are vital for the degree of smoothness and cutting efficiency of silicon wafers. Silicon carbide powder is the essence of silicon wafer cutting. With an appropriate particle shape, the surface of the silicon wafers presents a good degree of smoothness after cutting. Cutting efficiency can be improved by narrowing the particle size distribution and making the corner angle sharper.

There are 3 properties of materials which determine their ability to function as abrasives - Hardness, Sharpness and Toughness. Their hardness and sharpness reduce surfaces and their toughness is to withstand the abrading action. The surface being treated must have a hardness lower than the selected abrasive. A high hardness is necessary to grind, polish or remove surface.

Materials used as abrasives include garnet, diamond, silicon carbide, and aluminum oxide.

Particle size is an integral part of the proper selection and use of an abrasive. Traditionally, the measurements have been made by sieves. However, sieve measurements are limited in capability to measure very small sizes and are subject to shape bias only measuring the second largest dimension. Sizes for abrasives have a range from 6 millimeters to as small as 6 micrometers.

The shape of the particles is important to the effectiveness of the abrading action.

Sharpness is an indicator of the ability of a material to remove material from another surface. Asperity (roughness of the surface) affects wear rate of the under-treatment surface and effectiveness of the abrasive. The wear rate decreases below a certain abrasive particle size. The sharpness is determined by procedures such as the SPQ (Spike Parameter Quadratic) calculation, but with the Bettersize DIA system, it is possible to measure the angularity of a particle, which is far superior to using the Krumbein method.

Angularity may provide a better indication of sharpness than Krumbein. This is because angularity takes into account all pointed edges for particles, which is lacking in the Krumbein method.

Curated Resources

Related Particle Size Analyzer

-

BeNano 180 Zeta Pro

Nanoparticle Size and Zeta Potential Analyzer

Technology: Dynamic Light Scattering, Electrophoretic Light Scattering, Static Light Scattering

-

Bettersizer S3 Plus

Particle Size and Shape Analyzer

Measurement range: 0.01 - 3,500μm (Laser System)

Measurement range: 2 - 3,500μm (Image System)

-

Bettersizer 2600

Laser Diffraction Particle Size Analyzer

Measurement range: 0.02 - 2,600μm (Wet)

Measurement range: 0.1 - 2,600μm (Dry)

-

Bettersizer ST

One-stop Particle Size Analyzer

Dispersion type: Wet

Measurement range: 0.1 - 1,000µm

Repeatability: ≤1% variation

-

BeVision D2

Dynamic Image Analyzer

Dispersion type: Dry

Measurement range: 30 - 10,000μm

Technology: Dynamic Image Analysis

-

BeVision M1

Automated Static Image Analyzer

Dispersion type: Dry

Measurement range: 1 - 10,000μm

Technology: Automated Static Image Analysis

-

BeVision S1

Classical and Versatile Static Image Analyzer

Dispersion type: Dry & Wet

Measurement range: 1 - 3,000μm

Technology: Static Image Analysis

-

BeDensi T Pro Series

Tapped Density Tester with a Wallet-Friendly Solution

Number of Workstations: 1-3

Tapping Speed: 100 - 300 taps/min

Repeatability: ≤1% variation

-

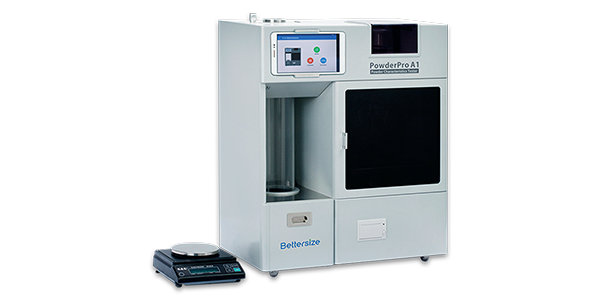

PowderPro A1

Automatic Powder Characteristics Tester

Operation Mode: Automatic

Tapping Speed: 50 - 300 taps/min

Repeatability: ≤3% variation

-

BT-Online1

Online Particle Size Analyzer

Dispersion type: Dry

Measurement range: 0.1 - 1,000μm

Accuracy: ≤1% (D50 of certified reference material)

-

BeDensi B1

Bulk Density Tester

Measurement: Bulk Density

Compliance with GB/T 16913

-

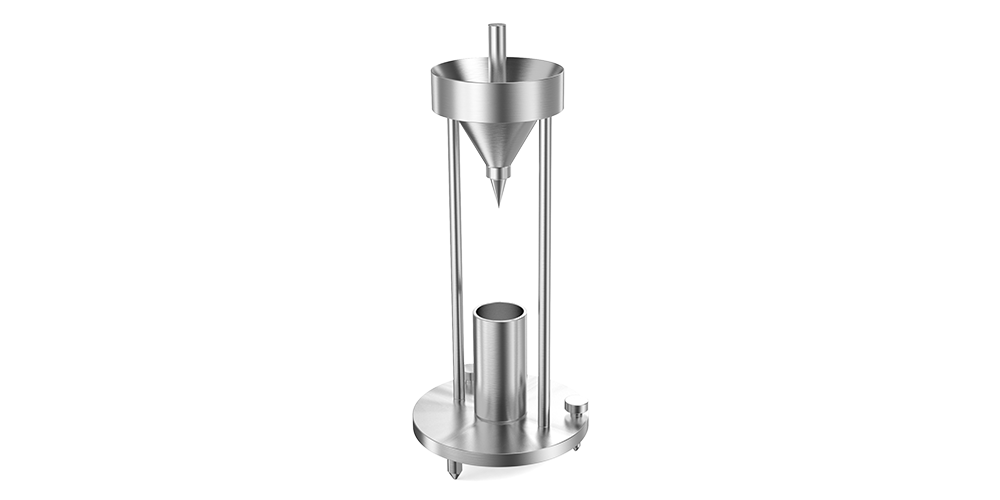

HFlow 1

Flowmeter Funnel

Measurement: Bulk density and Flow rate

Compliance with USP, Ph. Eur., ASTM, and ISO standards