Matching Cylinder Size to Powder Type for Accurate Density Testing

2025-10-22PowderPro A1, BeDensi T Pro Series

Matching Cylinder Size to Powder Type for Accurate Density Testing

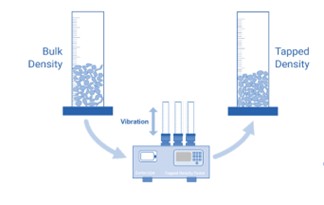

In powder characterization, especially when measuring tapped or bulk density, the volume of the measuring cylinder and the mass of the sample used can significantly affect the accuracy and repeatability of results. Choosing the wrong cylinder size can lead to high variability, incorrect packing behavior, or even non-compliance with standard procedures. This Lab Tip explores how to select the appropriate cylinder volume based on powder type, as outlined in three widely referenced standards: including USP <616>, Ph. Eur. 2.9.34, and JP XVIII 3.01 for pharmaceutical powders, as well as ISO 3953 for metallic powders and ASTM D7481 for granular materials.

1. Pharmaceutical Powders – USP <616> & Ph.Eur. 2.9.34 & JP XVIII 3.01

Pharmaceutical powders are typically light, fine, and cohesive. These three pharmacopoeias recommend using either a 250 mL or 100 mL graduated cylinder based on the amount of powder available.The 100 mL cylinder is a validated alternative when a 250 mL cylinder cannot be filled or when sample amount is limited.

These procedures are harmonized across the major pharmacopoeias, ensuring consistency and comparability in pharmaceutical powder testing worldwide.

Table 1. Recommended cylinder volume based on powder quantity

| Sample Suitability | Recommended Cylinder Volume | Stability Criterion |

|

Standard Powder (more than 100 g) |

250 mL |

Measure volumes at 10, 500, and 1250 taps: V10, V500, V1250.

|

|

Low-quantity Sample (if less than 100 g) |

100 mL |

|

2. Metal Powders – ISO 3953

Metal powders, due to their high density and variable particle size distribution, require appropriately selected cylinder volumes to ensure accurate and consistent tapped density measurements. ISO 3953 specifies the use of a 100 mL graduated cylinder as the standard apparatus for most metal powders.

For powders with an apparent density greater than 4 g/cm³, particularly refractory metal powders, a 25 mL graduated cylinder is recommended as an alternative to improve measurement precision. This smaller cylinder may also be used for lower-density powders when sample availability is limited or greater accuracy is required.

Table 2. Recommended cylinder volume based on apparent density

| Apparent Density (g/cm³) | Cylinder Volume | Test Mass |

| 1 – 4 | 100 mL | 100 ± 0.5 g |

| < 1 | 50 ± 0.2 g | |

| > 7 | 25 mL | 100 ± 0.5 g |

| 2 – 7 | 50 ± 0.2 g | |

| 0.8 – 2 | 20 ± 0.1 g | |

| < 0.8 | 10 ± 0.1 g |

3. Granular Powders – ASTM D7481

Granular materials such as activated carbon, formed catalyst and other moderately cohesive powders up to 3.5 mm in size are tested under ASTM D7481. This standard specifies pre-treatment using two sieves: a 4.00 mm (No. 5) top sieve and a 1.7 mm (No. 12) bottom sieve. Both sieves must be full-height and 200 mm (8 inches) in diameter, in accordance with ASTM E11. This step ensures that oversized particles are removed before testing.

The method allows the use of either a 100 mL or 250 mL graduated cylinder depending on the sample’s median particle size (d₅₀) and volume. Specifically, powders with d₅₀ ≤ 1.3 mm may use a 100 mL cylinder, while those up to d₅₀ = 1.7 mm may require a 250 mL cylinder.

Table 3. Recommended cylinder volume based on particle size

|

d₅₀ (median particle size, mm) |

Absolute max. particle size (mm) |

Graduated cylinder size (mL) |

Untapped apparent volume range (mL) |

| 1.3 | 2.5 | 100 | 50-100 |

| 1.7 | 3.5 | 250 | 125-250 |

Final Tip

Choosing the right measuring cylinder volume and corresponding sample mass is not a trivial task. It is determined by the physical characteristics of the powder—density, cohesiveness, and granularity. Following standard-specific guidelines ensures accurate and reproducible results, which are critical in formulation, quality control, and research settings.