Structural Insights into Thermally Expandable Alumina Microspheres via True Density Measurement

2025-10-21Application Note

Abstract: This study investigates the true density and expansion behavior of thermally expandable alumina microspheres in relation to their applications in lightweight composites, high-temperature insulation, and functional fillers. Using the gas displacement method, the hollow structure of the material was effectively characterized, providing a reliable foundation for performance evaluation and application-oriented material design.

Keywords: Thermally expandable microspheres, Ceramic, Alumina, True density, Lightweight materials

| Product | BetterPyc 380 |

| Industry |

Building Materials, Ceramics, Chemicals, Polymers and Plastics |

| Sample | Thermally Expandable Alumina Microspheres |

| Measurement Type | Density |

| Measurement Technology |

Jump to a section:

Introduction

Thermally expandable microspheres are hollow spheres composed of a thermoplastic shell encapsulating a volatile liquid or gas core. Upon heating within a defined temperature range, the core vaporizes and the shell softens, allowing the microspheres to expand significantly. Once cooled, the expanded structure solidifies, forming a stable, lightweight cellular material. This expanded form exhibits a combination of low density, high compressive strength, and excellent thermal insulation, making it suitable for applications in aerospace, automotive, construction, and polymer-based systems.

The expansion process results in a substantial increase in volume—often several times the original—while the true density decreases sharply, from approximately 1 g/cm³ to below 0.1 g/cm³. Notably, this volumetric expansion is irreversible, underscoring the importance of measuring true density both before and after thermal activation to assess lightweight performance and long-term stability.

Traditional density measurement techniques often struggle to accurately characterize porous or low-density materials. In contrast, a gas pycnometer offers a non-destructive, precise, and reproducible method for evaluating true density, making it particularly well-suited for analyzing the structural transformation of expandable alumina microspheres.

Figure 1. Expansion of unexpanded microsphere under application of heat

Instrument and Sample Description

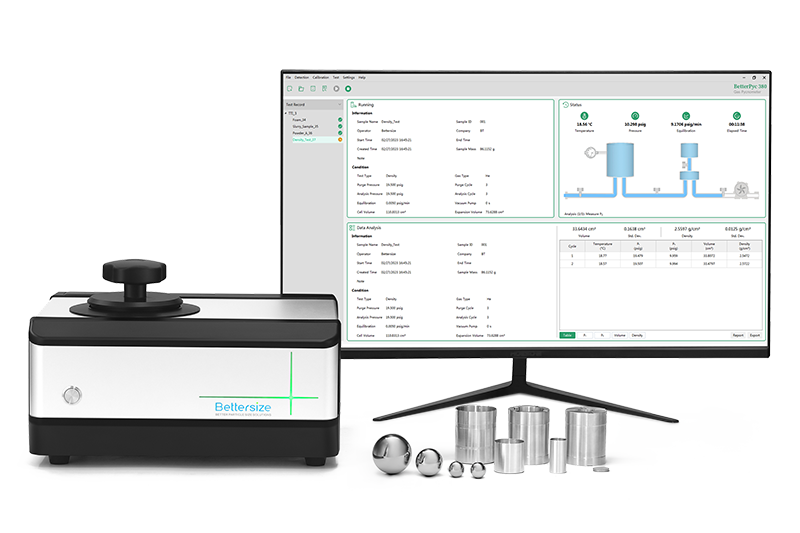

All measurements were performed using the BetterPyc 380, a fully automatic gas pycnometer designed to determine true density based on the principle of gas displacement. The instrument features dual reference chambers for compatibility with different sample cup sizes, a highresolution pressure transducer, and advanced software for automated control, data acquisition, and comparative analysis.

The measurement process involves placing a sample of known mass into a sealed chamber, which is then pressurized with an inert gas to a specific pressure. When the valve connecting the chamber to a reference volume of known size is opened, the gas expands, resulting in a measurable pressure drop. Using the ideal gas law (pV = nRT), the volume of the sample is calculated, and true density is then obtained by dividing the sample’s mass by its calculated volume.

Three alumina microsphere samples provided by the customer were selected for this study. The objective was to evaluate the change in true density before and after thermal expansion. According to the customer’s acceptance criteria, qualified microspheres must exhibit a post-expansion true density below 0.1 g/cm³.

Experimental Data Analysis

Each of the three microsphere samples was tested in triplicate, both before and after thermal expansion, under the conditions detailed in Table 1 to evaluate measurement accuracy and repeatability. This approach ensured consistent assessment of true density changes resulting from thermal activation, enabling reliable performance characterization in accordance with the customer’s acceptance criteria.

Table 1. Recommended measurement condition

| Parameter | Value | Parameter | Value |

| Temperature | 25 ℃ | Sample cup | 35 mL |

| Analysis Gas | Helium | Equilibrium | 0.01 psig/min |

| Analysis Pressure | 4.5 psig | Purge Pressure | 4.5 psig |

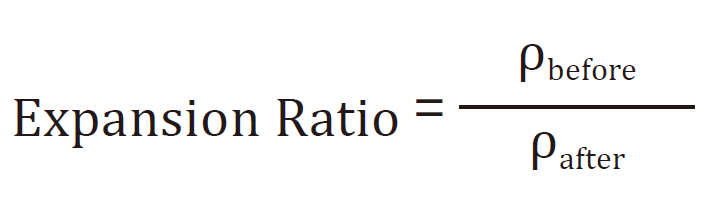

Table 2 summarizes the measured true density values for the three microsphere samples, recorded both before and after thermal expansion. The corresponding volumetric expansion ratios are also included, providing a direct comparison of structural changes induced by heating. These results offer a clear basis for evaluating the expansion performance and stability of the microsphere materials. The volumetric expansion ratio was calculated under the assumption of constant mass, as volume is inversely proportional to true density. Specifically, the expansion ratio is defined as the ratio of the initial true density to the post-expansion true density.

Table 2. True density and expansion ratio of microspheres before and after thermal expansion

| Sample | Average Measured True Density (g/cm3) | Volumetric Expansion Ratio | |

| Before Heat Expansion | After Heat Expansion | ||

| Microsphere-1 | 0.9999 | 0.0764 | 13.09 |

| Microsphere-2 | 1.0513 | 0.1303 | 8.07 |

| Microsphere-3 | 1.0162 | 0.1206 | 8.43 |

Table 3 shows the true density values for each microsphere sample, along with their corresponding standard deviations and pass/fail status based on the customer’s acceptance criterion.

Table 3. True density results of three microsphere samples

| Sample | Average Measured True Density (g/cm3) | Std. Dev | Meets Acceptance Standard (<0.1 g/cm³) |

|||

| 1 | 2 | 3 | Ave. | |||

| Microsphere-1 | 0.0766 | 0.0753 | 0.0773 | 0.0764 | 0.0008 | Yes |

| Microsphere-2 | 0.1306 | 0.1298 | 0.1306 | 0.1303 | 0.0004 | No |

| Microsphere-3 | 0.1213 | 0.1202 | 0.1202 | 0.1206 | 0.0005 | No |

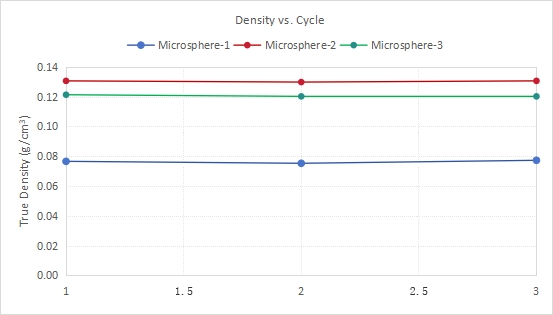

Figure 2. Comparison analysis among three microsphere samples

Figure 2 presents a comparative analysis of the true density results for the three microsphere samples, automatically generated by the BetterPyc 380 software.

This visual representation enables intuitive assessment of material compliance, clearly distinguishing the qualified batch (Microsphere-1) from the unqualified batches (Microsphere-2 and Microsphere-3) relative to the customer’s specification threshold. The integrated software not only streamlines data acquisition but also enhances reporting and decision-making by providing clear graphical evidence of performance outcomes.

Discussion

Clear Differentiation Between Qualified and Unqualified Batches

Based on the customer’s acceptance criterion (<0.1 g/ cm³), only Microsphere-1 met the requirement, while Microsphere-2 and Microsphere-3 exceeded the threshold with average post-expansion densities of 0.1303 g/cm³ and 0.1206 g/cm³, respectively. These results demonstrate the effectiveness of true density measurement as a quantitative and objective method for material screening and selection.

High Measurement Repeatability

All three microsphere samples exhibited low standard deviations, confirming the BetterPyc 380’s capability to deliver stable and repeatable measurements even for extremely lightweight and porous materials. This level of consistency is essential for quality control , enabling manufacturers to distinguish batch-to-batch variations from measurement noise.

This analysis supports the use of true density testing in raw material screening, incoming inspection, and process validation. Understanding the change in true density before and after thermal expansion provides key insights into expansion completeness and internal structural stability—critical factors influencing long-term mechanical and thermal performance. Early identification of noncompliant microsphere batches helps prevent downstream issues such as inconsistent mechanical strength, weight imbalance, and reduced insulation efficiency.

Conclusion

The results confirm that the BetterPyc 380 gas pycnometer is highly suitable for characterizing the true density of thermally expandable alumina microspheres both before and after thermal expansion. With standard deviations below 0.001 g/cm³, the instrument delivers precise and repeatable measurements, providing strong support for material screening, process control, and product design in both R&D and routine production.

About the Authors

|

Feiqing Shen |

|

BetterPyc 380

Accurascy meets versatility

|

|