Measuring Particle Size Distribution of Calcium Carbonate Powders with Laser Diffraction Method

2021-09-14Application Note

Laser diffraction measures calcium carbonate particle size for QC. Crucial for optimizing the sizing process and meeting diverse industry needs.

| Product | Bettersizer ST |

| Industry | Mining and Minerals |

| Sample | Calcium carbonate |

| Measurement Type | Particle Size |

| Measurement Technology | Laser Diffraction |

Jump to a section:

Abstract: Over a wide range of industries, different functions require different particle size distributions of ground calcium carbonate powders. That is the reason why particle sizing is a vital step for quality control of ground calcium carbonate. In this investigation, particle size distributions of three different ground calcium carbonates were measured by the laser diffraction method. Typical size values and size distribution curves were compared to evaluate the quality and stability of the sizing process of the three samples.

Keywords: Particle size distribution, calcium carbonate, GCC, laser diffraction, quality control

Introduction

The ground calcium carbonate (GCC) powder is usually produced by crushing and grinding natural white calcites, as shown in Figure 1. The GCC powder has a different variety of functions over a wide range of industries: it can be used as a filler for concrete in the construction industry, ceramic tiles, blackboard chalk, iron ore purification, oil well drilling fluids, paints, adhesives, sealants and as an acidity controller in the paper industry. Most of these functions require different specific particle size distributions (PSD) of GCC powders. Accordingly, measuring PSD regularly is vital for the quality control process after mining and Grinding.

Measuring Particle Size Distribution of Calcium Carbonate Powders

Three GCC powder samples were measured by the Bettersizer ST in this investigation. All three samples (GCC samples A, B, and C) were measured after they were classified and packed. All measurements were repeated six times to ensure repeatability. The GCC samples were dispersed by the built-in wet dispersion unit of the Bettersizer ST for this experiment.

The patented dual lens optical systems (DLOS) of the Bettersizer ST provide a 0.1-1000 μm measuring range, capable of measuring these GCC powders and most other grades of calcium carbonate. With the DLOS technology, the Bettersizer ST can provide the user with rapid, accurate, and highly repeatable PSD measurement results. These PSD results are required to fully optimize the calcium carbonate products and ensure they comply with the industry standards and requirements.

PSD Curves Help to Evaluate the Quality of GCC Powders

During the classification and sorting process before being packed and shipped, all three GCC powder samples were sifted by a 325 sieve mesh. That ensures almost all particles in these GCC powder samples should be smaller than 45 μm, which is the mesh size of an opening on the 325 sieves. Bettersizer ST was used to measure the particle size distributions and percentiles of GCC powder samples A, B, and C, whose typical size values are listed in Table 1.

| Sample name |

D10(μm)

|

D50 (μm)

|

D90 (μm)

|

| GCC Sample A | 2.290 | 16.14 | 35.61 |

| GCC Sample B | 2.289 | 16.07 | 36.54 |

| GCC Sample C | 2.095 | 15.78 | 34.79 |

According to Table 1, the D90 of Samples A, B, and C is smaller than 45 μm. That means 90% of the particles in these three samples pass through a 325 sieve mesh, which implies most of the particles in these samples meet the size requirement.

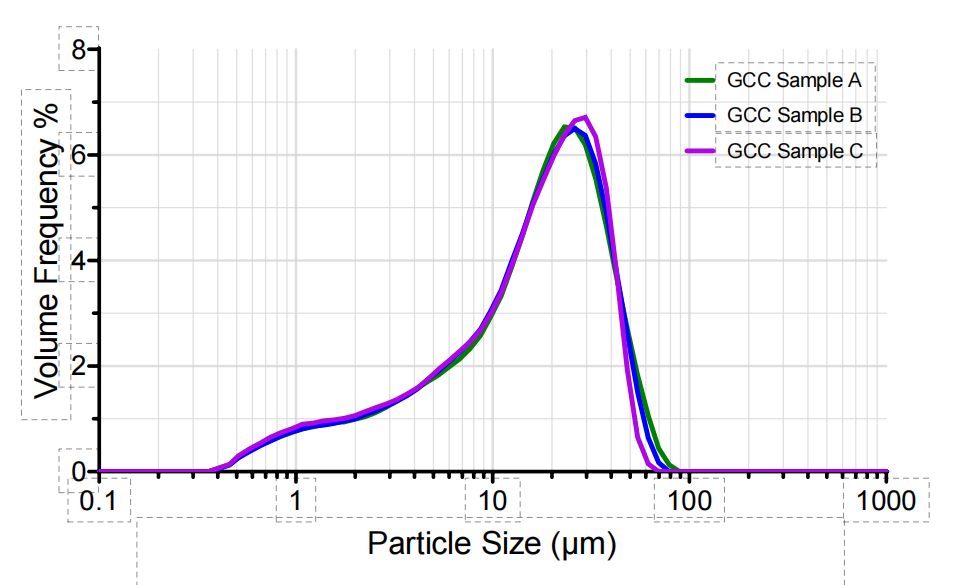

To evaluate the size distribution of GCC powder products, we measured and compared the PSD curves of GCC samples A, B, and C, which are shown in Figure 2.

As Figure 2 shows, three GCC powder samples are similar in size distribution mode and range. That suggested the quality of these calcium carbonate products is under control, in terms of particle size. The slightly smaller size of the GCC sample C implies there are fewer coarse particles in sample C. But in total, the PSD results of these GCC powder products are stable.

Sizing Results From Bettersizer ST With High Repeatability

PSD measurements of every sample were repeated six times to ensure repeatability. The results of the typical size values of GCC powder sample C are listed in Table 2.

| Record number | D10 (μm) | D50 (μm) | D90 (μm) |

| Sample C-1 | 2.097 | 15.7 | 34.92 |

| Sample C-2 | 2.097 | 15.7 | 34.87 |

| Sample C-3 | 2.089 | 15.66 | 34.83 |

| Sample C-4 | 2.106 | 15.95 | 34.75 |

| Sample C-5 | 2.106 | 15.95 | 34.71 |

| Sample C-6 | 2.095 | 15.87 | 34.68 |

| Repeatability error | 0.32% | 0.85% | 0.25% |

| Average | 2.095 | 15.78 | 34.79 |

According to Table 2, for typical size values, repeatability errors of measurement results are small and conform to the ISO 13320 standard, suggesting the Bettersizer ST can produce repeatable and reproducible sizing results.

Conclusions

Requirements of particle size and size distributions of GCC powder products vary over a wide range. Controlling PSD of GCC powder products is vital for both GCC producers and their customers. The Bettersizer ST is an efficient and reliable instrument that provides particle sizing solutions to the product quality control process of most mining industries, as well as providing incoming quality control of GCC powder for most industrial applications. Its sensitivity in spotting small differences between samples A, B, and C gives the user the confidence to look back at the production process and diagnose the reason for small or large differences in particle size distribution.

About the Authors

|

Weichen Gan Senior Engineer @ Application Research Lab, Bettersize Instruments Ltd.

|

|

The Bettersizer ST is a fully automated and integrated particle size analyzer with a smart operation system for wet dispersing.

|

|

Recommended articles

Rate this article