Application of Image Particle Size & Shape Analysis System in Abrasive

2019-07-01Application Note

This note compares laser scattering and image methods for abrasive particle size/shape. Image method yields better accuracy and higher coarse particle resolution, effectively monitoring size, distribution, ovality, and circularity. This ensures product uniformity, enhances abrasive tool performance, and makes it an indispensable detection method.

| Product | BeVision S1 |

| Industry | Abrasives |

| Sample | Silicon Carbide Abrasive |

| Measurement Type | Particle Size, Particle Shape |

| Measurement Technology | Laser Diffraction, Image Analysis |

Jump to a section:

Abstract: We learned the influence of abrasive particle size on the performance of abrasive tools with literature investigation. This paper mainly compares the particle size and particle shape distribution of different kinds of abrasive by laser scattering method and image method. The results show that the accuracy of particle size measurement results adopted by image method is better and coarser particle resolution is higher, which can effectively monitor the particle size, particle size distribution and ovality, circularity in the abrasive production process to ensure the uniformity of the product, thus improving the performance of the abrasive tool, therefor, the image method is one of the indispensable detection methods in the abrasive industry.

Keywords: Abrasive, laser scattering method, image method, particle size, particle shape

Abrasive tools are mainly composed of three elements: abrasives, binders and pores. Abrasives are the soul of abrasive tools. The quality of abrasives (chemical composition, hardness, crush resistance, self-sharpness, thermal stability, particle size, hydrophily, microstructure, bulk density, etc.) directly determine the performance of the abrasive tools which can be produced by alumina

(Al2O3), silicon carbide (SiC), SG, diamond and other materials. Abrasive particle size directly affects the roughness of the workpiece surface, grinding efficiency and the generation of grinding heat. In actual production applications, the choice of abrasive particle size should be matched with the material of the workpiece, machining accuracy, production process and other factors. For example, when processing the same kind of workpiece, wet grinding processing uses fine abrasives compared to dry grinding processing. If lubricating oil is used as the coolant, a finer abrasive particle size should be used. In general, medium-particle abrasives are the most widely used, and fine abrasives are mostly used for fine grinding, grinding and polishing. In the batch production to ensure the roughness of the workpiece, the coarse abrasive should be selected as much as possible to improve the productivity. However, in the small batch production, the fine abrasive should be considered to improve the processing quality of the workpiece. Abrasive particle shape directly affects the number of effective grinding particles, bulk density, etc., which in turn affects the hardness and cutting performance.

of the abrasive tools and is always affected by factors such as the chemical composition of the abrasive, the manufacturing method and the fragmentation method. For instance, an equal-shaped abrasive has high impact strength and strong grinding ability. The flaky and sword-shaped abrasives have good sharpness and are more suitable for coated abrasive tools.

With the development of abrasive processing machinery and equipment, the processing range of using abrasive tools is wider and wider, the processing precision and smoothness are getting higher and higher, and new requirements are imposed on abrasive particle size distribution and particle shape distribution. Therefore, the detection method and technology of micro-powder abrasives have also received further attention. At present, the detecting methods of micronized particle size in the abrasive industry mainly include sedimentation, Coulter counter (resistance method), laser scattering method and image method. The principle of each detection method can be quite different, which leads to deviations between the results. Even the results of the two batches of micronized abrasives detected by the same instrument are consistent, but the using effect is quite different. This paper will study the application of particle size and particle shape in abrasive production, which will provide an effective reference for the selection of reasonable particle size detection methods for abrasive quality monitoring and product controlling.

1. Particle size measuring instrument

Generally, the advantages and disadvantages of different particle size detection methods are shown in Table 1. Considering the operability and applicability of different particle size test methods. This paper mainly focuses on the application of laser scattering and image method in abrasive quality monitoring and product controlling.

|

Sedimentation

|

Coulter

|

Laser scattering

|

Image

|

|

|

Principle

|

Stokes law

|

Small hole resistance method

|

Mie scattering method

|

Pixel statistics

|

|

Advantage

|

1. The instrument is cheap

2. Simple operation

|

1. High-resolution

2. Count particle number

|

1. Easy to operate, fast

test, wide test range,

good repeatability

2. Dry and wet test

|

1. Test particle size

and shape

2.Checking the

dispersion state

|

|

Disadvantage

|

1. Testing speed is slow

2. Not suitable for flaky

particles

3. Hard to measure samples

below 2um

4. Can’t test mixed samples

with different densities

|

1. Not suitable for wide

suspension

2. Small hole tube is easy to

block

3. Hard to measure samples

below 2um

4. Must be tested in electrolytes

|

1. low resolution for

coarse particle

2. Need sample optical

parameters, affected by

the distribution model

|

1. The image below

2um is not clear and

the error is large

|

2. Experiment

2.1 Instrument

- BeVision W1 Image Particle Size & Shape Analysis System from Dandong Bettersize Instrument Ltd.

- Bettersizer S3 Laser Particle Size Analyser from Dandong Bettersize Instrument Ltd.

- BeVision S1 Image Particle Size Analyzer from Dandong Bettersize Instrument Ltd.

2.2 Sample and reagent

- Three different sizes of silicon carbide abrasives

- Deionized water

- Surfactant

3. Measurement and results

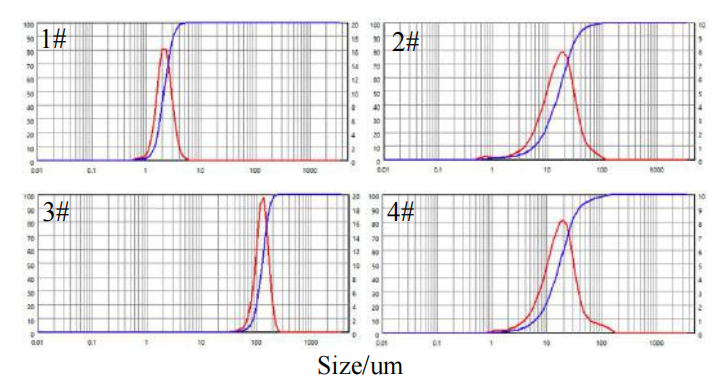

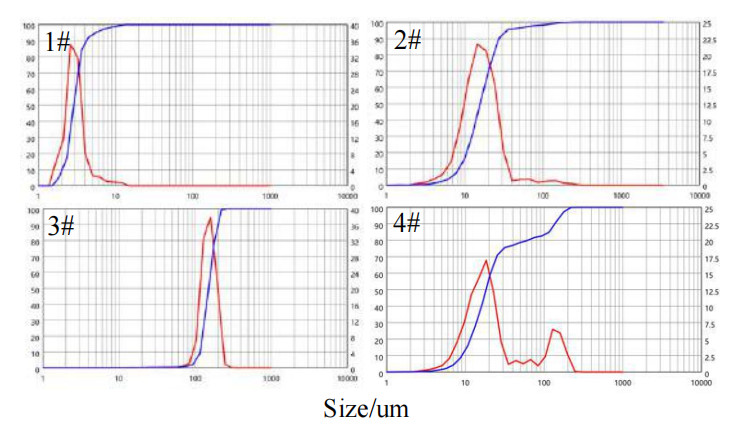

Whether the quality of the micronized abrasive product is stable or not depends mainly on the particle size distribution, the coarse end particles, and the abrasive shape. Therefore, the ability of different methods to detect the large particle resolution and abrasive shape of the abrasive coarse end is mainly investigated. In this paper, three kinds of silicon carbide abrasives with different particle size were considered. At the same time, 2#_Middle and 3#_Coarse silicon carbide abrasives were used to configure the coarse mass fraction with 10% mixed abrasive system 4#_Mixed. The results of particle size distribution of different samples are shown in the Table 2 and Figure 1&2.

|

Method

|

SN.

|

Typical particle size /um

|

Shape parameter

|

||||

| D10 | D50 | D90 | D97 |

Aspect Ratio

|

Circ.

|

||

|

Laser

|

1#_Fine

|

1.425

|

2.012

|

3.148

|

3.835

|

/ | / |

|

2#_Middle

|

5.824

|

16.27

|

35.17

|

54.05

|

/ | / | |

|

3#_Coarse

|

92.90

|

143.2

|

211.5

|

252.0

|

/ | / | |

|

4#_Mixed

|

6.494

|

17.29

|

38.69

|

74.87

|

/ | / | |

|

Image

|

1#_Fine

|

2.292

|

2.864

|

4.077

|

6.805

|

1.214

|

0.955

|

|

2#_Middle

|

8.395

|

15.94

|

27.39

|

59.52

|

1.472

|

0.866

|

|

|

3#_Coarse

|

117.7

|

150.9

|

196.6

|

217.3

|

1.264

|

0.89

|

|

|

4#_Mixed

|

9.107

|

18.19

|

137.0

|

176.4

|

1.458

|

0.868

|

|

Figure 1. Particle size distribution of the 1#_Fine, 2#_Middle, 3#_Coarse and 4#_Mixed in laser scattering

Figure 2. Particle size distribution of the 1#_Fine, 2#_Middle, 3#_Coarse and 4#_Mixed in imaging method

3.1 Ability to detect coarse-end particles

Due to the diversification of the purchase channels of the company using micro-powder, it is impossible to ensure that the production processes of all suppliers are consistent, which may lead to fluctuations in the coarse ends of the abrasives, thus may affect the performance of the products. The coarse-end particle resolution refers to the resolution of the weight ratio of the detection method to the coarse particles, which is calculated as follows:

R represents the resolution of the coarse-end particles

Pt represents the mass percentage of the 3#coarse sample in the mixed sample (10% in this example)

Di represents the D90 or D97 difference between 4#_Mixed and 2#_Middle silicon carbide

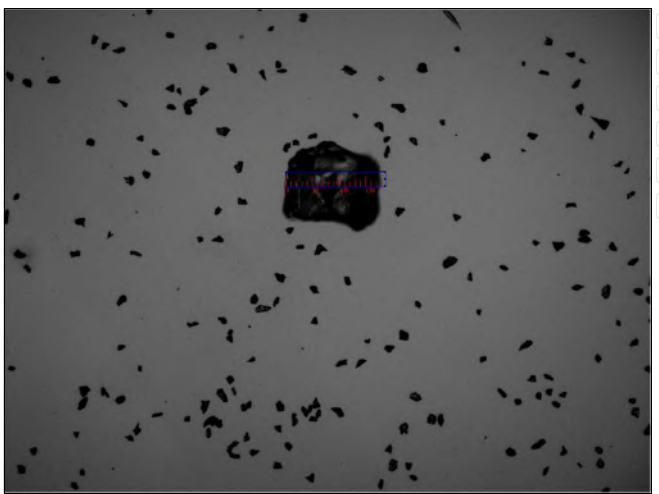

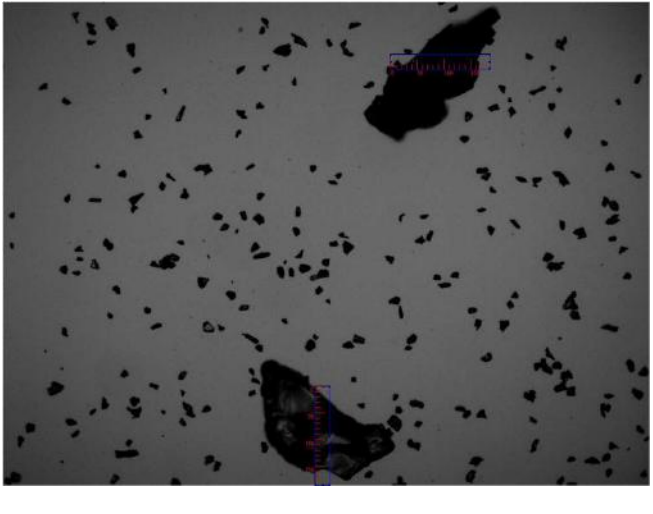

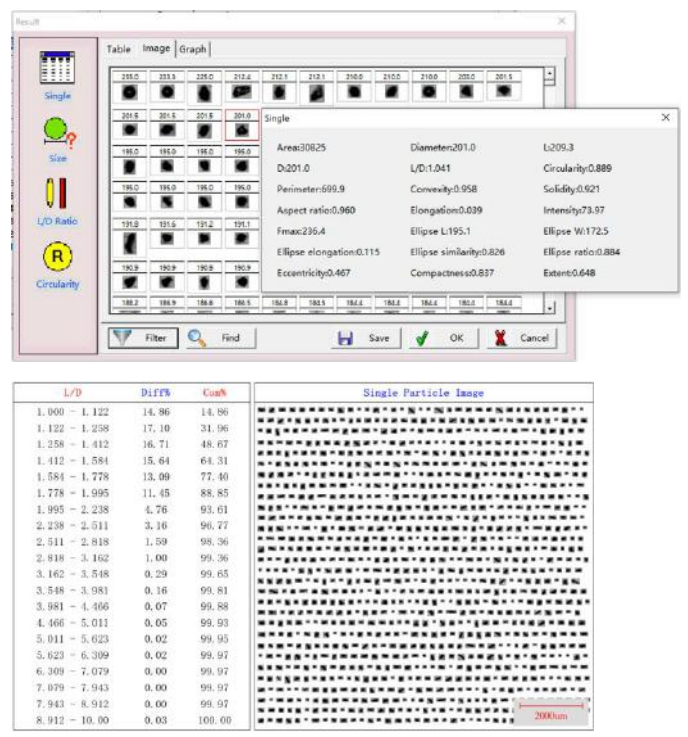

The distribution of coarse particles in the 4#_mixed sample during each sampling process was observed by BeVision S1, as shown in Fig. 3. The results showed that for the mass fraction of 10% mixed 4# sample, there were coarse particle in each sampling process.

According to the data in formula (1) and Table 2, the resolution of the coarse particles by the laser scattering method and the image method are respectively calculated as shown in Table 3. The calculation results show that the resolution of the image method is much higher than that of the laser scattering method. The reason why the laser method causes this phenomenon is because the quantity of coarse particles is small, the coarse particles will intermittently pass through the laser beam, so the scattered signals will appear intermittently, which are easily filtered by subsequent data processing. Therefore, the inversion calculation does not have coarse particle information. In addition, since the detectors that receive the light scattering signals of the coarse particles are concentrated near the center point of the concentrated spot, the background value of the detector is highly affected by the concentrated spot. The interference of the noise on the coarse particle scattering signal also affects the detection of the coarse particle scattering signal.

|

Detection method

|

D90 resolution

|

D97 resolution

|

|

Laser scattering method

|

2.84%

|

0.48%

|

|

Image method

|

0.091%

|

0.085%

|

ISO13320:2009 particle size distribution (laser diffraction method) also provides that the number, position and geometry of the detector elements, the signal-to-noise ratio, the fine structure in the measured scattering pattern, adequacy of the optical model all prevent the laser diffraction technique in its usual design from being a high-resolution technique. Therefore, for a small amount of coarse-end particle image method is more suitable for monitoring the particle size and particle size distribution of the abrasive during the production process.

3.2 Ability to detect particle shape

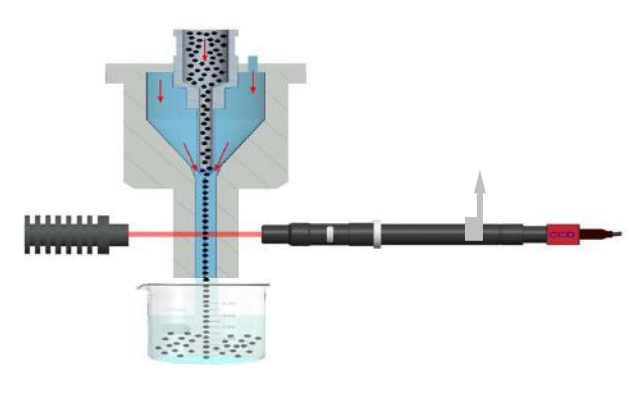

BeVision W1 uses sheath flow technology to constrain sample flow to make particle projections clearer, the principle of sheath flow as show in Figure 4, thus ensuring the accuracy of measurement results. Whether the quality of the micronized abrasive product is stable or not depends mainly on the particle size distribution, the coarse-end particles, and the shape of the abrasive. For some samples with substantially the same particle size distribution, the performance of the product is significantly different due to the different particle shape distribution. At present, only the image method detects multiple parameters such as the equivalent circular area diameter, ellipticity, circularity, aspect ratio, and eccentricity, etc., as shown in Figure 5, at the same time it can achieve the particle size distribution and a higher resolution of coarse-end particle, which completely meet the requirements for the detection and controlling of the three elements of micro-powder quality evaluation. Image theory is feasible, operability is strong, the test results are objective, the physical meaning is clear, and it is comparable and verifiable. Therefore, the image method is a comprehensive and reliable method for quality inspection and control of micronized abrasive tools.

4. Conclude

1) The resolution of the image method for the coarse-end particles is much higher than that of the laser scattering method, and it is more effective to monitor the particle size and particle size distribution of the abrasive during the production process.

2) The image method can obtain information of the abrasive particle shape and size, which is one of the indispensable detection methods in the abrasive industry.

About the Authors

| Alvin Wang, Hongyang Li Application Engineers @ Bettersize Instruments |

Recommended articles

Rate this article