Application of BT-Online1 Laser Particle Size System in Cement Industry

2019-07-01Application Note

Optimizing cement particle size distribution is crucial for product quality and energy saving, impacting concrete performance and durability. This note compares cement particle size data from BT-Online1 and a lab laser analyzer at varying mill speeds, with BeVision S1 verifying coarse particle size.

| Product | BT-Online 1, BeVision S1 |

| Industry | Building Materials |

| Sample | Cement |

| Measurement Type | Particle Size |

| Measurement Technology | Laser Diffraction, Image Analysis |

Jump to a section:

Abstract: The particle size distribution of cement directly affects the physical and mechanical properties of cement, concrete construction performance and durability, and optimizing the particle size distribution of cement is significant for improving product quality and reducing energy consumption, which has received more and more attention from researchers. In this paper, the cement particle size distribution between BT-Online1 laser particle size system and laboratory laser particle size analyzer under different mill speeds was compared and the coarse particle size of cement was also verified by BeVision S1 image particle size analyzer. The research results show that BT-Online1 provides accurate and effective cement particle size distribution and has a good correlation with the trend of wet sieve (screening) results. At the same time, it

realizes the real-time monitoring of the particle size distribution of cement products, which optimizes the parameters of cement production process to improve product quality, reduce energy consumption and reduce production costs.

Keywords: cement, particle size distribution, BT-Online1

Cement is the raw material of economic construction and its particle size distribution directly affects the physical properties such as cement hardening rate, strength and fluidity, which determines the applicability, durability and economy of concrete, and is closely related to the quality of engineering. The engineering practice of the cement plant shows that the cement performance can be significantly improved through optimizing the cement grinding process and improving the particle size distribution, it can also meet the different requirements of customers for cement performance by adjusting the cement particle size distribution.

GB175-2007 "General silicate cement" specifies the particle size representation method of 80μm or 45μm sieve residue method and specific surface area (SSA) method, wherein the sieve residue method has a wide range of use, but the SSA method is more closely related to cement performance and better characterizes the particle size than the sieve residue method. However, there is also a problem of inaccurate testing for the porous or over-fine material with SSA method. Since each component of the cement corresponds to different properties, even if the sieve result is the same or SSA is similar, the performance of the cement may show a significant difference, so both the sieve residue method and the SSA method are partially characterize the particle size of cement and are impossible to obtain the whole particle size distribution of cement, which is unattainable for controlling cement production and giving full play to the performance of various

components of cement. Only the particle size distribution test can fully characterize the size and composition of cement particles, making up for the limitations of traditional particle size testing methods. The laser particle size analyzer has been widely used in the particle size testing industry due to its unique testing speed, wide test range, good reproducibility and high sensitivity. With the emergence of new dry process technology in the cement industry and the emergence of DCS distributed control systems, the importance and necessity of online particle size system units has increased. This paper makes a preliminary research on the performance of the BT-Online1 laser particle size monitoring and control system and its application in the cement industry.

1. Experiment

1.1 Instrument

- BT-Online1 Laser Particle Size System from Dandong Bettersize Instrument Ltd.

- Bettersizer SD Laser Particle Size Analyzer from Dandong Bettersize Instrument Ltd.

- BeVision S1 Image Particle Size Analyzer from Dandong Bettersize Instrument Ltd.

1.2 Sample and reagent

- Cement, domestic and international cement company

- Pure compressed air

- Anhydrous ethanol

2. Measurement and results

2.1 Particle size distribution under different mill speeds of raw material mill system

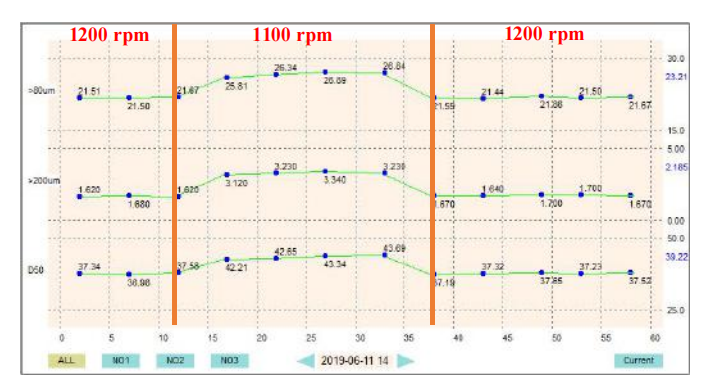

In order to investigate the particle size monitoring performance of the raw material grinding system of BT-Online1, the raw material production line of a domestic cement company in China was studied. The particle size distribution of cement under different speeds of the classifier is shown in Fig. 1, when the speed is reduced from 1200 rpm to 1100 rpm, >80um and >200um cement content will be correspondingly larger, which fully meets the process requirements; when the speed is increased from 1100 rpm to 1200 rpm, >80um and >200um cement content which is completely consistent with the initial result will be correspondingly smaller. It can be seen that BT-Online1 can timely and effectively monitor the system granularity state of raw material grinding system to meet the control requirements of raw material production.

2.2 Particle size distribution under different mill speeds of cement mill system

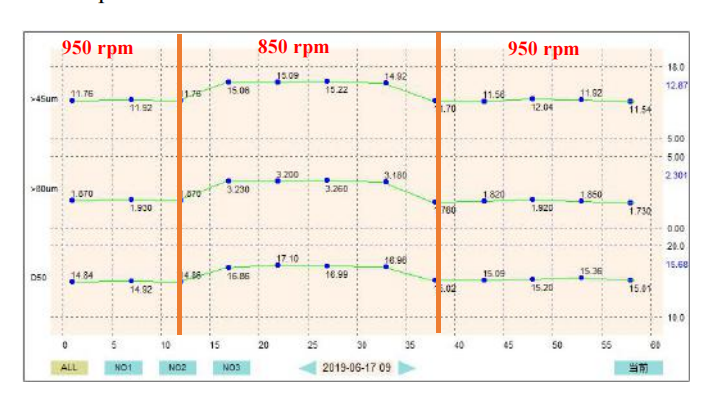

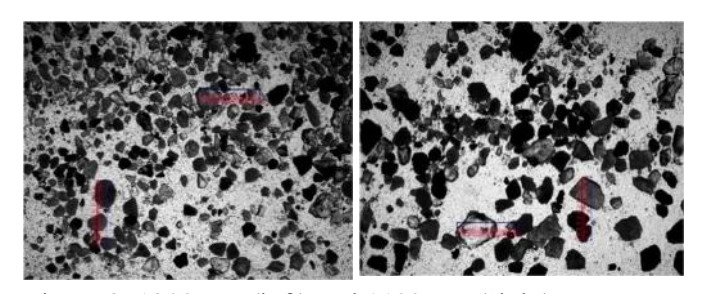

In order to investigate the particle size monitoring performance of the cement grinding system of BT-Online1, the cement production line of a domestic cement company in China was studied. The particle size distribution of cement at different speeds of the classifier (850 rpm and 950 rpm) is shown in Fig. 2. It shows that when the speed is reduced from 950 rpm to 850 rpm, >45um and >80um cement content will be correspondingly larger, the cement particle size will become larger, which fully meets the process requirements; when the speed is increased from 850rpm to 950rpm, >45um and >80um cement content will be correspondingly smaller, which is completely consistent with the initial result. At the same time, it can be found that the coarse particle size and content of the cement at 850rpm is higher than 950rpm through BeVision S1 image particle size analyzer, as shown in Fig. 3. Therefore, the parameters of cement grinding system can be effectively monitored by BT-Online1 to ensure the quality stability of cement products.

Figure 2. Particle size distribution of cement under different separator speeds

Figure 3. 1200rpm (left) and 1100rpm (right) cement image under 4X objective

2.3 BT-Online1 compared with lab instruments

In order to investigate the accuracy and stability of the online instrument, under the above conditions, this experiment also comparatively studied the cement particle size distribution between the laboratory laser particle size analyzer and BT-Online1 laser particle size system, as shown in Table 1, the trend of particle size distribution and specific value of Bettersizer SD and BT-Online1 are consistent. The accuracy of BT-Online1 has reached the laboratory instrument, which fully meets the requirements of particle size in monitoring industrial production process.

|

Speed

|

Model

|

D10/um

|

D50/um

|

D90/um

|

|

850 rpm

|

Bettersizer SD

|

2.713

|

16.57

|

53.76

|

|

2.812

|

17.10

|

54.55

|

||

|

BT-Online1

|

2.813

|

16.96

|

54.38

|

|

|

2.795

|

16.86

|

54.61

|

||

|

Repeatability

|

1.48%

|

1.15%

|

0.62%

|

|

|

950 rpm

|

BT-9300LD

|

2.418

|

14.81

|

47.75

|

|

2.475

|

15.02

|

48.14

|

||

|

BT-Online1

|

2.493

|

15.09

|

47.91

|

|

|

2.459

|

14.92

|

48.57

|

||

|

Repeatability

|

1.13%

|

0.71%

|

0.64%

|

2.4 BT-Online1 compared with wet screening

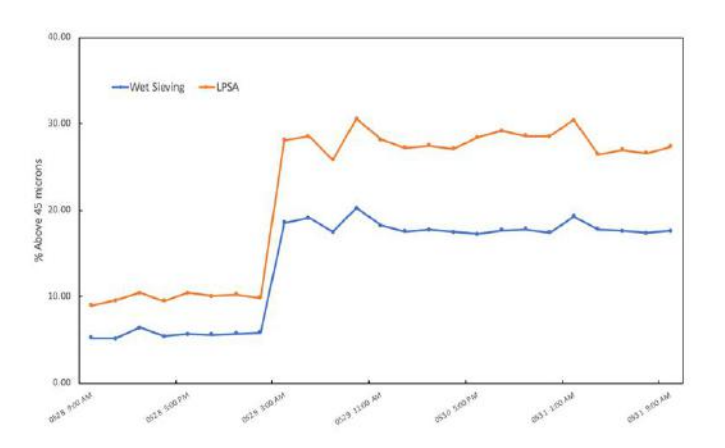

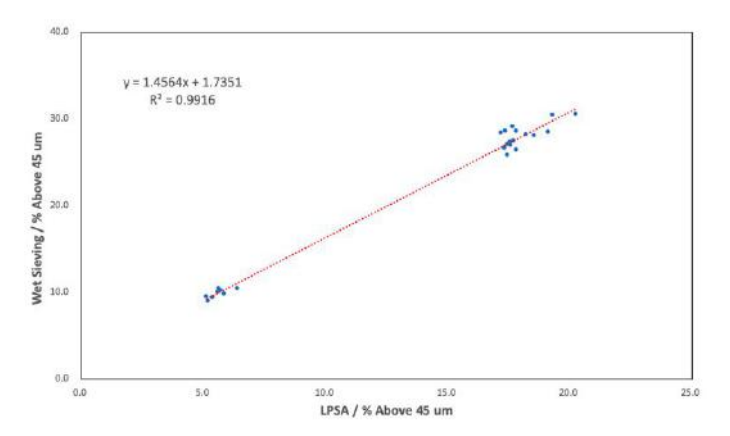

According to the cement samples of a large foreign silicate cement company, the distribution of 45um cement content on the wet screening and the BT-Online1 was compared under different process parameter over time, as shown in Fig. 4. At the same time, >45um cement content distribution of two methods is shown in Figure 5. The results show that >45um cement content distribution trend of BT-Online1 is completely matched with the wet screening under different process parameters, and the difference between two methods is approximately constant under relevant production process. The fluctuation mainly comes from the instability of wet screening and the representative difference of sampling. Through multiple-data processing, the distribution of key variables of LPSA and wet screening can be correlated, while taking into account the advantages of laser method, BT-Online1 can completely replace wet screening method to monitor cement production.

3. Conclude

1) BT-Online1 laser particle size system can maintain the same precision as laboratory laser particle size analyzer

2) BT-Online1 laser particle size system and the wet screening have consistent trend and wet screening can be completely replaced. 3) BT-Online1 can monitor the particle size distribution of cement products in real time, effectively optimize the cement production process parameters to improve product quality, reduce energy consumption and production costs.

About the Authors

| Alvin Wang, Hongyang Li Application Engineers @ Bettersize Instruments |