Breaking the Unbreakable: BeNano to Outsmart PFAS at Toho University

2026-01-22News

In the landscape of materials science, per- and polyfluoroalkyl substances (PFAS) represent a formidable adversary. Commonly termed "forever chemicals" due to their unparalleled persistence, these compounds feature exceptionally strong carbon-fluorine bonds that render them nearly impervious to natural degradation. Their widespread historical use has led to global contamination of water sources, ecosystems, and biological tissues. This creates one of the most pressing environmental challenges of our era.

At the Konno Laboratory within Toho University's Department of Biosphere Environmental Science, researchers have initiated a sophisticated research initiative. Rather than attempting to break these indestructible bonds through brute force, the team led by Associate Professor Hiroki Konno has developed an innovative strategy: engineering molecular traps at the nanoscale. Their approach centers on deliberately designing imperfections in advanced materials to capture and remove PFAS from contaminated systems. Critical to validating this strategy is their use of the BeNano 180 Zeta nanoparticle analyzer, an instrument that provides essential data to transform theoretical concepts into viable purification technologies.

From right to left: Hiroki Konno (Associate Professor), Mr. Taiga (M1 Student), and Ms. Tanikawa (Sanyo Technos Co., Ltd.)

This groundbreaking research, accepted for publication in the high-impact journal Separation and Purification Technology, demonstrates how precise nanoparticle characterization enables new solutions for addressing persistent environmental pollutants.

Read the original article here: External link

The PFAS Challenge: Why "Forever Chemicals" Are So Difficult to Remove

PFAS represent one of the most significant environmental challenges of our time. Their extreme persistence, coupled with widespread historical use in everything from non-stick coatings to firefighting foams, has led to global contamination. Traditional water treatment methods like activated carbon filtration struggle with inconsistent removal efficiency, while destructive methods like incineration require extremely high temperatures and carry risks of incomplete breakdown.

This technological gap has mobilized researchers worldwide to develop innovative PFAS remediation approaches that are both effective and practical for large-scale implementation.

Scientific Breakthrough: Engineering Defects to Trap PFAS

At the forefront of this research is Associate Professor Hiroki Konno and his team, whose innovative approach focuses on metal-organic frameworks (MOFs). These are highly porous, crystalline nanomaterials with exceptional surface areas—some exceeding 6,000 square meters per gram—making them theoretically ideal for contaminant capture.

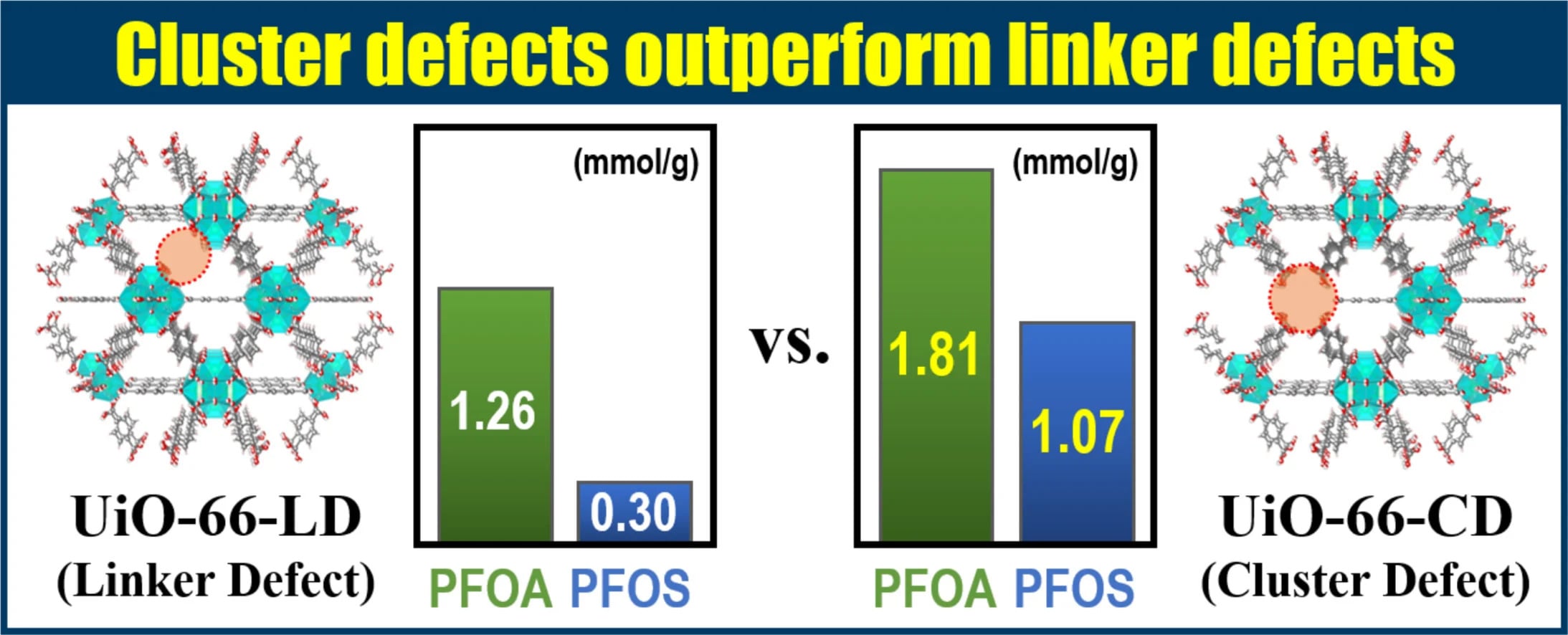

The Toho University team's breakthrough involves deliberately engineering defect sites within the crystalline structure of a specific MOF called UiO-66. Rather than trying to create perfect crystals, the researchers introduce controlled imperfections that create tailored binding pockets specifically designed to capture PFAS molecules more effectively.

"Our work represents a paradigm shift from simply using materials as we find them to actively redesigning them at the molecular level," explains Associate Professor Konno. "By strategically designing defects in the MOF structure, we can create adsorption sites with enhanced affinity and selectivity for specific PFAS compounds."

Cluster Defects Outperform Linker Defects

Introduction and Selection of BeNano 180 Zeta

Until now, the Konno Laboratory had instruments capable of measuring the particle size of relatively large particles; however, no instrumentation had been introduced for evaluating particles in the nanoparticle size range.

In this study, which focused on metal–organic framework (MOF) materials such as UiO-66, it was necessary to obtain a more detailed understanding of surface properties, requiring nanoparticle size and zeta potential measurements.

During the instrument selection process, products from other manufacturers based on the same measurement principles were also considered. However, after a comprehensive comparison of factors including:

- Technical specifications, such as support for a 180-degree detection angle

- Cost-performance balance within the available research budget

The laboratory concluded that BeNano 180 Zeta, manufactured by Bettersize, was better suited to the measurement requirements of the study. The key factor leading to the decision was the ability to reliably perform the required nanoparticle and zeta potential evaluations within a limited budget.

Key On-site Considerations During the Evaluation and Selection Process (Associate Professor Konno)

When considering the introduction of the instrument, we evaluated not only the specifications and price, but also the post-purchase maintenance and support system. Although we also received explanations of products from other manufacturers, we ultimately felt that purchasing from Sanyo Technos (formerly Sanyo Trading—Bettersize’s distributor in Japan)—with whom we had an established business relationship—provided a greater sense of reassurance.

Prior to installation, demonstration measurements were arranged promptly, allowing us to verify measurement results using our actual samples. In addition, clear explanations were provided regarding after-sales support, which gave us confidence that the instrument would be suitable for research applications.

We also felt that a continuous and stable partnership existed between Sanyo Technos and Bettersize, leading us to conclude that the instrument could be trusted for long-term use.

In our current research environment, we do not judge the quality of an instrument solely based on its country of manufacture (domestic or overseas). After observing the instrument firsthand and conducting demonstration measurements, we found that BeNano was more suitable in terms of performance, ease of use, and cost. Furthermore, BeNano offers a comprehensive product lineup, allowing us to select a model that matches our research requirements and budget, which further contributed to our confidence during the introduction process.

Prof. Konno and Mr. Taiga Working at BeNano 180 Zeta

The Hands-on Usage

Measurements with BeNano 180 Zeta can be performed through a simple operation: placing the sample into the cell and pressing the instrument button. This makes it a highly user-friendly instrument in the research environment. In addition, the instrument demonstrated high measurement reproducibility. Even in multiple measurements under varying conditions and comparative experiments, stable and reliable data acquisition was achieved.

In this study, measurements were primarily conducted by students. However, thanks to the clear and intuitive operating procedures, which do not require extensive training or experience, BeNano was able to be used routinely and without difficulty within the laboratory. During operation, there was one occasion when an inquiry was made to Sanyo Technos, and the issue was resolved promptly due to their quick response. As a result, the measurement and research workflow proceeded smoothly without interruption, allowing the study to progress efficiently overall.

At present, BeNano 180 Zeta is mainly used for zeta potential measurements, and the research group also plans to further utilize it for particle size measurements in the future.

Key Impressions from Hands-on Use of the Instrument (Mr. Taiga)

Although the laboratory routinely uses a variety of measurement instruments, BeNano stood out as being particularly easy to handle. When explaining the operating procedures to junior students, a single explanation was sufficient for them to understand, which proved to be a significant advantage in daily laboratory operations. There were no issues regarding measurement reproducibility. As long as proper care was taken in preparing dispersion solutions and sample pretreatment—such as ensuring sufficient dispersion through ultrasonic treatment—highly reproducible measurement results were obtained.

The user interface and display were intuitive and natural in Japanese, and the simplified user manual was easy to understand, resulting in very few instances of confusion during operation.

Another notable point was that measurements could be started on the very day the instrument was delivered. While some measurement instruments require considerable time for initial setup and calibration, BeNano involved minimal preparation and could be quickly put to use in research activities.

Mr. Taiga Working at BeNano 180 Zeta

About BeNano 180 Zeta

In this study, the BeNano nanoparticle size and zeta potential analyzer manufactured by Bettersize and distributed by Sanyo Technos was used to characterize the surface electrical properties (zeta potential) of the materials.

The BeNano system enables multiple measurements to be performed on a single instrument, including:

- Particle size distribution

- Zeta potential

- Molecular weight

- Microrheology

For zeta potential measurements, the instrument employs PALS (Phase Analysis Light Scattering) technology, which allows for high-sensitivity evaluation even for samples exhibiting low zeta potential.

In addition, optional accessories and functions are available, such as:

- An automatic pH titration unit

- High-resolution particle size measurement in flow mode

These features make the system suitable for a wide range of nanomaterial and particle research applications.

Conclusion

The battle against PFAS contamination requires innovative approaches at the intersection of materials science, chemistry, and environmental engineering. The work at Toho University demonstrates how precision nanoparticle characterization with the BeNano 180 Zeta is enabling researchers to develop smarter, more effective materials for environmental remediation.

By providing detailed insights into material properties and interactions at the nanoscale, advanced analytical technologies are accelerating the development of solutions in materials science. As research continues, the integration of sophisticated measurement capabilities with creative material design promises to deliver increasingly effective tools for PFAS remediation.

Editor’s Note: This article was authored by Sanyo Technos, Bettersize’s distributor in Japan, and originally published in Japanese.

The research work and perspectives introduced belong to the Konno Laboratory at Toho University.

Recent News