A Buyer's Guide to Particle Size Analyzers: Price, Features & More

2026-01-12News

A Buyer's Guide to Particle Size Analyzers: Price, Features & More

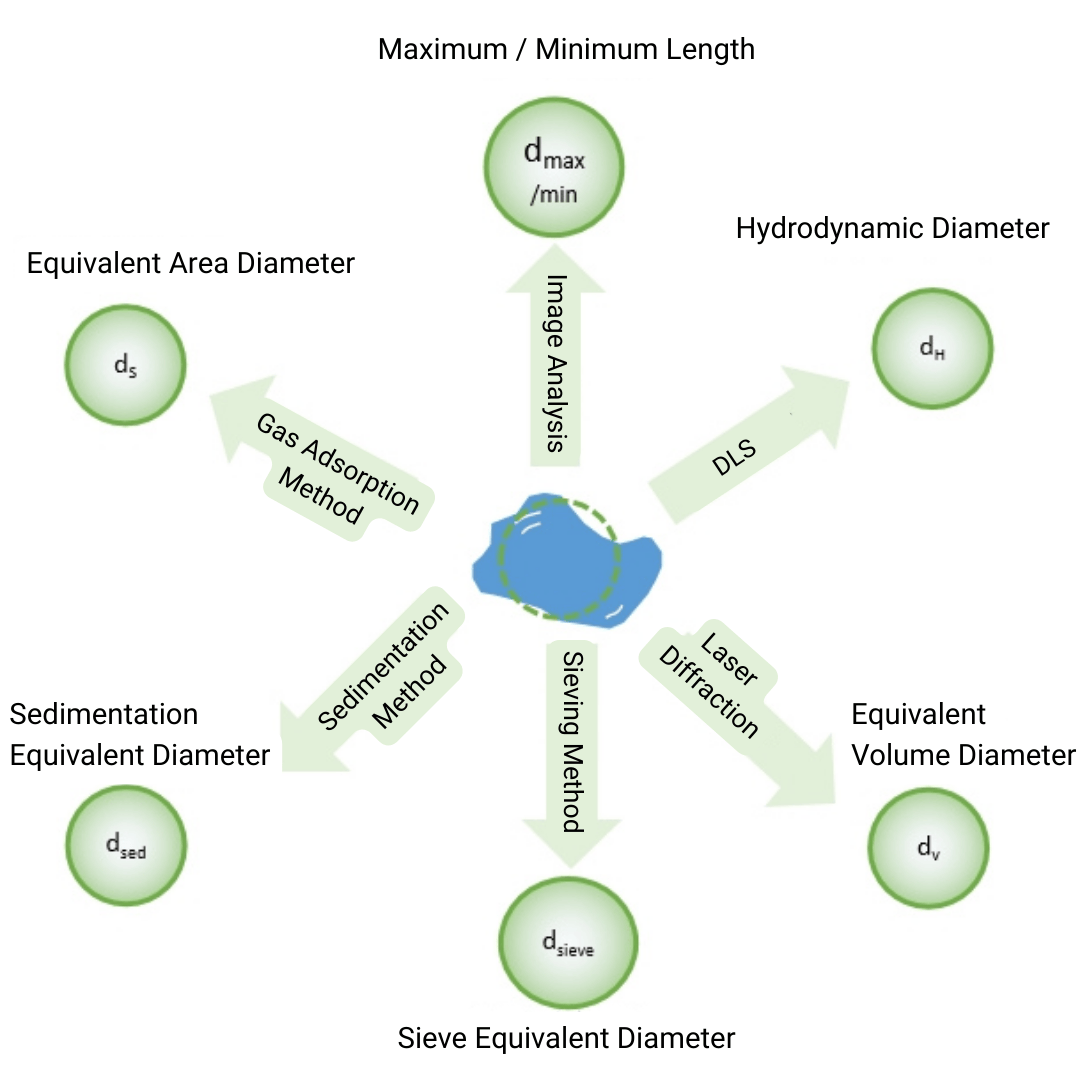

Particle size analysis is used to quantify how materials are distributed across a range of particle sizes and how that distribution affects performance. Early methods for particle size analysis, such as sieving, sedimentation, and manual microscopy, provided approximate classifications but were limited by low resolution and operator dependence. Modern particle size analyzers apply optical and acoustic measurement techniques to generate reproducible particle size distributions. The choice of particle size analyzer should be based on how well its measurement technology, system features, and operating scope align with the material being matched and the decisions the data is expected to support. For buyers, the challenge lies in selecting a particle size analyzer that meets technical specifications and delivers reliable, application-relevant results over the long term.

Choosing the Right Particle Size Measurement Technology

Different particle size analysis methods are designed around distinct physical principles, and each performs best within specific size ranges and sample types, and with specific analytical goals.

Laser diffraction

Laser diffraction is the most widely used technique for particle size analysis due to its broad applicability and operational efficiency. By analyzing how particles scatter light at different angles, it delivers fast, statistically robust particle size distributions across an extensive measurement range. Its compatibility with both wet and dry dispersion makes it suitable for routine quality control as well as formulation and process development.

Dynamic light scattering

Dynamic light scattering (DLS) is optimized for particles in the nanoscale range. Instead of relying on gravitational effects, it measures fluctuations in scattered light caused by Brownian motion. This makes DLS particularly effective for nanoparticles, emulsions, and protein systems where conventional particle size analysis methods, such as sieving, lack sufficient sensitivity or resolution.

Dynamic image analysis

Dynamic image analysis provides direct visual information by capturing images of particles as they move through the measurement zone. In addition to particle size, it quantifies shape-related parameters such as aspect ratio and surface characteristics. Such a capability is important when particle shape affects flowability, packing efficiency, or the likelihood of segregation.

Acoustic spectroscopy

Acoustic spectroscopy is applied to particle systems that are highly concentrated or optically opaque. Instead of using light, it measures how sound waves propagate through a suspension to determine particle size. Because the technique operates at high solids concentrations, it allows dense slurries to be analyzed in their native state, avoiding dilution steps that could change particle interactions or structure.

Rather than picking a particle size analyzer based solely on specification level, buyers should focus on choosing the measurement method and instrument configuration that best match their material properties, concentration range, and intended use of data under real laboratory and process conditions.

Features That Define Measurement Quality

Resolution and Sensitivity

Measurement quality depends on a particle size analyzer's optical or detection resolution, not just its stated size range. A capable particle size analyzer should reliably separate overlapping particle populations and detect small shifts in distribution, supported by appropriate detector design, optical configuration, and data processing algorithms.

Dispersion Capability

Accurate particle size analysis depends on whether a particle size analyzer can disperse the sample into its primary particles in a controlled and repeatable manner. This requires dispersion systems matched to material behavior, such as high-energy dry dispersion with adjustable air pressure for cohesive powders, and stable wet circulation with controlled pump speed or ultrasound for fragile particles. Additionally, for materials prone to agglomeration or rapid sedimentation, the particle size analyzer must maintain consistent dispersion throughout the measurement to avoid biased distributions.

Material and Sample Compatibility

A particle size analyzer must be designed to handle the chemical and physical constraints of real samples. Chemical-resistant wetted parts are essential when working with aggressive solvents or reactive suspensions. Low-volume dispersion systems are critical for expensive or limited materials, where sample conservation is important. Temperature control is also vital for polymers, biological materials, and emulsions, helping preserve sample state and measurement repeatability.

Particle Size Analyzer Pricing Ranges

Particle size analyzers typically fall into three pricing tiers, with cost reflecting flexibility, automation, and analytical depth.

Standard quality control systems ($15,000–$35,000)

Single-technology particle size analyzers optimized for the routine monitoring of stable, well-characterized materials, prioritizing robustness and ease of use.

R&D-focused systems ($35,000–$70,000)

Higher resolution particle size analyzers with modular wet and dry dispersion options, supporting method development, troubleshooting, and material variation.

Advanced research platforms ($75,000–$120,000+)

Multi-technology particle size analyzers or specialized nanoparticle analyzers that provide deeper insight, including combined size and shape analysis or zeta potential measurements.

Particle Size Analyzers from Bettersize Instruments

Bettersizer 2600

Bettersizer S3 Plus

BeNano Series

Learn More About our Particle Size Analyzers

To determine which particle size analyzer would best suit your materials and measurement requirements, contact Bettersize Instruments to discuss your application with an experienced specialist.

Recent News