- ● Introduction

- ● PowderPro Series and BeDensi Series

- ● What are bulk density, tapped density and compressibility, flowability index?

- ● What are angle of repose, angle of fall, angle of difference, and flat plate angle (angle of spatula)?

- ● How to measure flowability of metal powders?

Introduction

Powder characterization includes rheology, morphology, particle size distribution, density, and chemical composition. Bettersize PowderPro series and BeDensi series instruments are mainly used for the analysis of the powder physical properties by testing items, such as the angle of repose, the angle of fall, the angle of spatula (flat plate angle), bulk and tapped density, dispersibility, voidage and cohesion, the angle of difference, compressibility, uniformity, flowability index, floodability index, sieve size.

PowderPro Series and BeDensi Series

BeDensi T Pro Series

Tapped Density Tester with a Wallet-Friendly Solution

Number of Workstations: 1-3

Tapping Speed: 100 - 300 taps/min

Repeatability: ≤1% variation

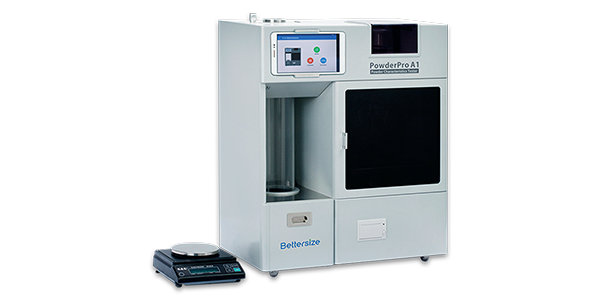

PowderPro A1

Automatic Powder Characteristics Tester

Operation Mode: Automatic

Tapping Speed: 50 - 300 taps/min

Repeatability: ≤3% variation

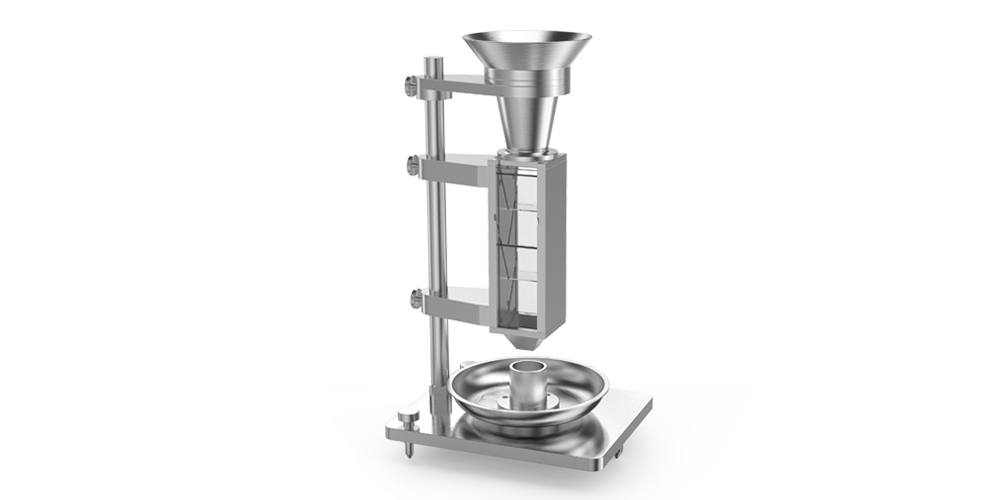

BeDensi B1

Bulk Density Tester

Measurement: Bulk Density

Compliance with GB/T 16913

BeDensi B1-S

Scott Volumeter

Measurement: Bulk Density

Compliance with USP, Ph. Eur., ASTM, and ISO standards

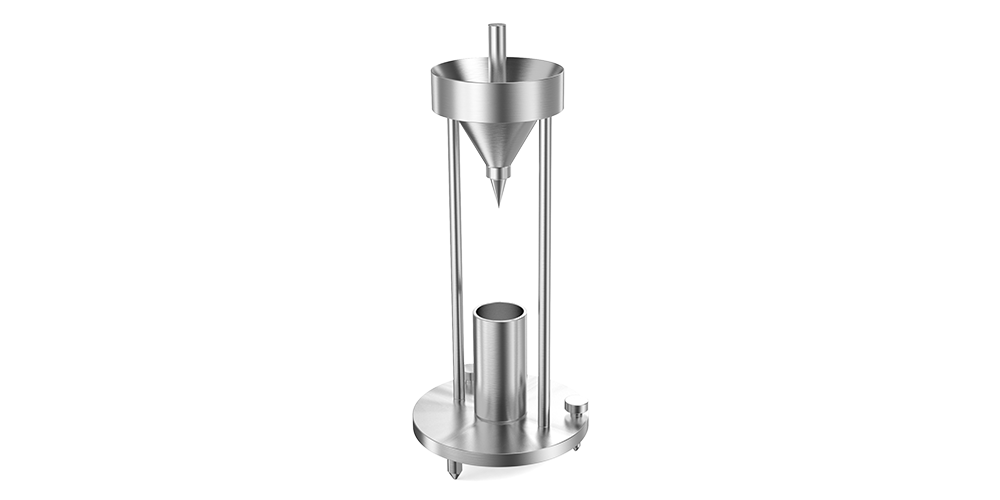

HFlow 1

Flowmeter Funnel

Measurement: Bulk density and Flow rate

Compliance with USP, Ph. Eur., ASTM, and ISO standards

BeDensi P

Bulk Density Tester - Plastic

Measurement: Bulk Density

Compliance with ISO and GB/T standards

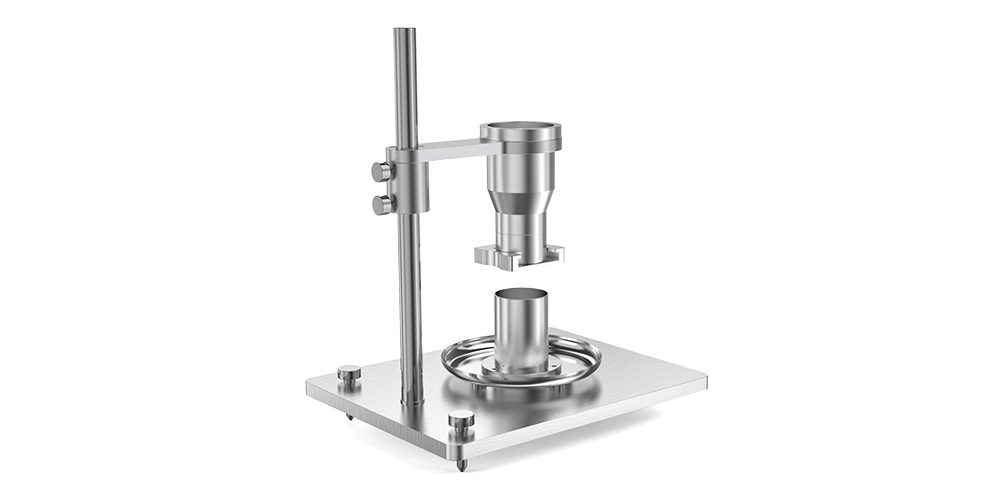

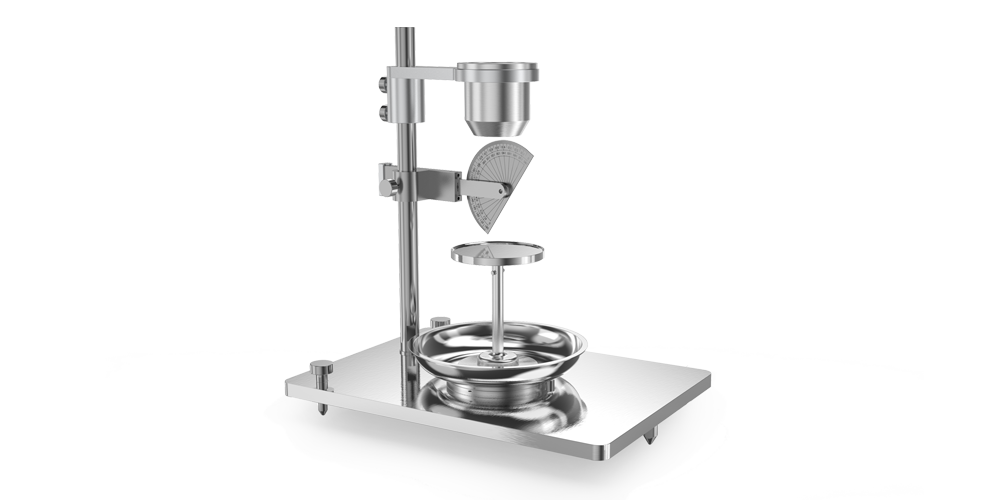

BeDensi AR

Angle of Repose Tester

Measurement: Angle of Repose

Compliance with USP and Ph. Eur. standards

What are bulk density, tapped density and compressibility, flowability index?

Bulk density: fill the powder sample into a measuring cup, and flatten the top, the ratio of the powder mass to the volume of the cup is defined as bulk density. It indicates the mass of the powder that can be added into the vessel per volume under normal conditions.

Tapped density: fill the powder sample into a measuring cup; vibrate the cup at a certain amplitude and frequency to remove air from the powders. After reaching the required vibration time, flatten the sample. The ratio of the powder mass to the volume of the cup is defined as tapped density. Tapped density indicates the mass of powders filled into the vessel per volume after excluding air from the powders. The data of bulk density and tapped density are often used for the design of vessels, bags, and tanks for powder storage.

Compressibility: it is the ratio of the difference between tapped density and bulk density to tap density. It shows the degree of volume reduction from bulk to tap state.

Flowability Index: is a set of numerical values obtained by the weighted summation of angle of repose, Compressibility, angle of spatula, uniformity, and cohesion. It is used to comprehensively evaluate the flowability of the powder. The Flowability Index is mainly used to describe powder flowability under gravity.

What are angle of repose, angle of fall, angle of difference, and flat plate angle (angle of spatula)?

Angle of repose: Under the static balance, the angle between the slope of a powder pile and the horizontal plane is angle of repose. It is measured when the powders fall to a surface via gravity and form a cone. It indicates the flowability of the powders. The smaller the angle of repose is, the better the flowability of the powders.

Angle of fall: After measuring the angle of repose, apply an external force to the powder pile to collapse it. The angle between the slope of the collapsed pile and the horizontal plane is defined as angle of fall.

Angle of difference: It means the difference between the angle of repose and the angle of collapse. The larger the angle of difference is, the better flowability of the powders.

Flat plate angle: immerse a plane in the powder pile; pull up the plane vertically, and one angle is formed between the slope of the powders on the plane and the plane. Apply an external force to obtain another angle. The average of these two angles is flat plate angle. The smaller the flat plate angle is, the better the flowability of the powders. The flat plate angle is usually larger than the angle of repose.

How to measure flowability of metal powders?

According to ISO4490, the flowability of metal powders is usually measured with a Hall flow meter.

The measurement process is:

- Weigh 50g + 0.1g sample;

- Plug the hole in the funnel with the finger;

- Pour the sample into the funnel;

- Quickly remove the finger from the small hole and start the stopwatch at the same time (precision 0.2S);

- Wait until the powder sample runs out, and stops the timing immediately;

- Evaluate the fluidity of the metal powder through the time of the 50g powder passing through the hole.

The standard funnel of the Hall flowmeter needs to be calibrated by a standard sample with a flow speed of 40 + 0.5s/50g.