BeVision S1

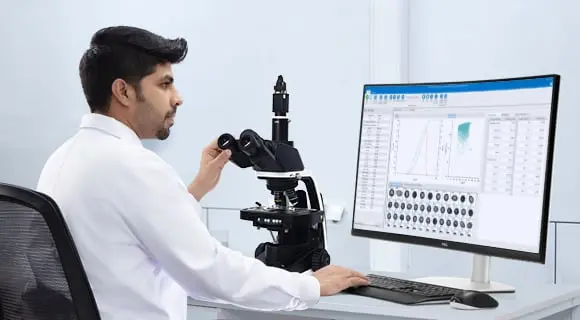

The BeVision S1 integrates light microscopy and image analysis to deliver size and shape distributions of both powders and suspensions. With an objective magnification of up to 100x, the BeVision S1 efficiently analyzes and records particles as fine as 0.3 μm.

Features and Benefits

- ● Biological microscope and metallographic microscope for option

- ● Measurement range: 0.3 to 4,500 µm (biological microscope); 0.1 to 2700 µm (metallographic microscope);

- ● Both dry and wet measurements

- ● 34 different particle size and shape parameters

- ● 4 optional test modes for different applications

- ● Results in compliance with ISO 9276-6

- ● Powerful software eases your work

- ● Customizable reports for different evaluation options

- ● A budget - friendly solution for your particle analysis