Revealing the Secret of Cosmetics Using Laser Diffraction and Static Multiple Light Scattering

2026-02-17Application Note

Abstract: In cosmetic products, particle size and distribution play a crucial role in determining product performance, including texture, opacity, and efficacy. This study investigates the particle size distribution, shape, bulk density, and flowability of cosmetic powders using laser diffraction and static multiple light scattering. The findings highlight the importance of optimizing particle size and stability to improve the quality, consistency, and user experience of cosmetics like foundations, sunscreens, and exfoliating creams.

Keywords: Cosmetics, Particle size distribution (PSD), Particle shape, Laser diffraction, Static multiple light scattering, Bulk density, Flowability, 3D printing, Exfoliating creams, Sunscreens

| Product | Bettersizer 2600 Plus |

| Industry | |

| Sample | Cosmetic powders and formulations |

| Measurement Type | Particle Size, Particle Shape, Stability |

| Measurement Technology |

The History of Cosmetics:

|

|

The use of cosmetics is deeply rooted in human history, with origins dating back tens of thousands of years. The earliest cosmetic practices involved the grinding of natural minerals and are believed to have originated during the Stone Age. Archaeological discoveries from ancient Egypt vividly illustrate these traditions, as seen in the iconic eyeliner and eyeshadow depicted on the Bust of Nefertiti.

At that time, makeup served purposed beyond aesthetic enhancement, and it also conveyed spiritual significance, social status, and even protective power. In ancient China, particularly during the Tang dynasty, women commonly drew their eyebrows with water-dispersed pigments and applied lead-based powders to whiten their complexion. Despite the toxicity of some materials, such practices persisted until the late 19th century, when modern cosmetic formulations began to take shape.

Today, driven by a growing emphasis on personal appearance, cosmetics constitute a multi-billion-dollar global industry. Many cosmetics are either powder-based or formulated as dispersed systems, such as suspensions and emulsions, making particle size analysis and stability evaluation critical to their development and performance.

|

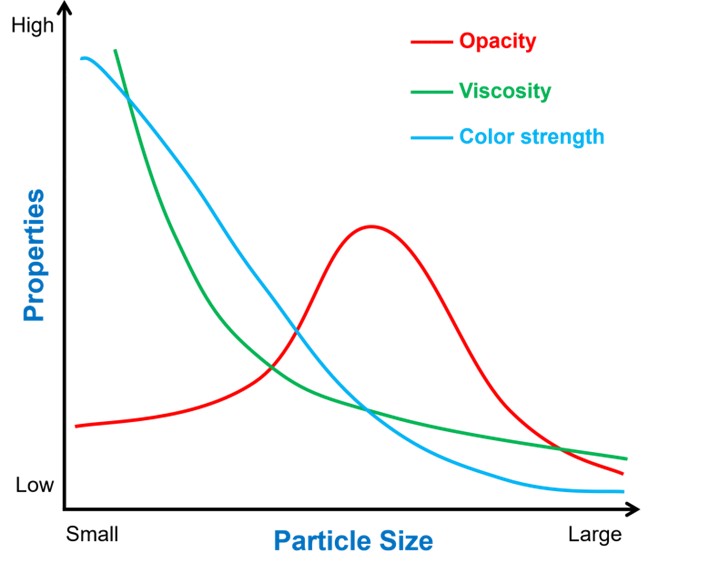

The Critical Role of Particle Size and Stability |

Particle size plays a defining role in the performance and safety of cosmetics products. When the size of active ingredients does not meet formulation requirements, issues such as poor skin texture or reduced product efficacy can arise. For example, inappropriate particle size in liquid foundations may cause caking or an uneven finish, while in moisturizing creams it can lead to an uneven oil film and an unpleasant tactile sensation.

In more severe cases, inadequately formulated cosmetic products may pose health risks. For instance, excessively large particles in mud masks can increase mechanical friction on the skin, potentially triggering irritation, inflammation or allergic reactions, particularly in individuals with sensitive skin.

Optimizing particle size can significantly enhance the performance of a wide range of cosmetic products. Here are some examples:

-

In sunscreens, smaller titanium dioxide particles provide more uniform coverage and improved UV protection.

-

In exfoliating or scrub creams, active ingredients with well-controlled particle sizes improve cleaning efficiency while minimizing skin roughness.

-

In color cosmetics such as eyeshadows, an appropriate pigment particle size and size distribution contribute to uniform color payoff, whereas the particle size of glitter flakes directly affects sparkle intensity and overall visual appeal.

Therefore, particle size analysis is a critical component of formulation development, manufacturing, and quality control in the cosmetic industry, as it directly determines product consistency and performance.

For liquid and semi-solid formulations, dispersion stability is as essential as particle size, as it influences not only product performance but also shelf life and redispersibility. In cream-based cosmetics, good stability reflects well-dispersed active ingredients, a smooth and lightweight texture, and a prolonged shelf life. In contrast, poorly designed formulations may exhibit unstable phenomena, such as coalescence, creaming, or phase separation, ultimately compromising both product quality and consumer experience.

| Bettersizer 2600 Plus: A Versatile Particle Size Solution for Cosmetic Analysis |

|

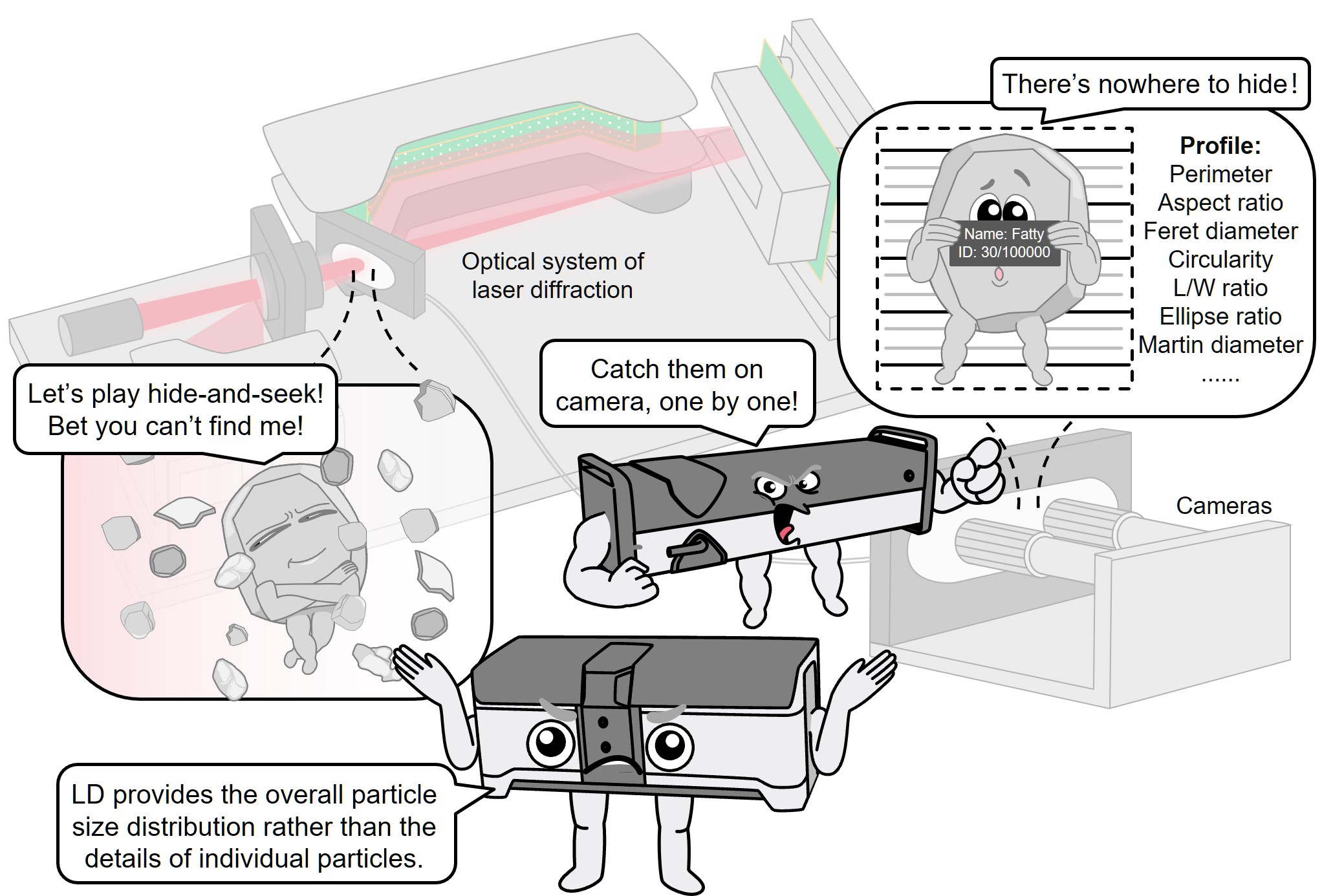

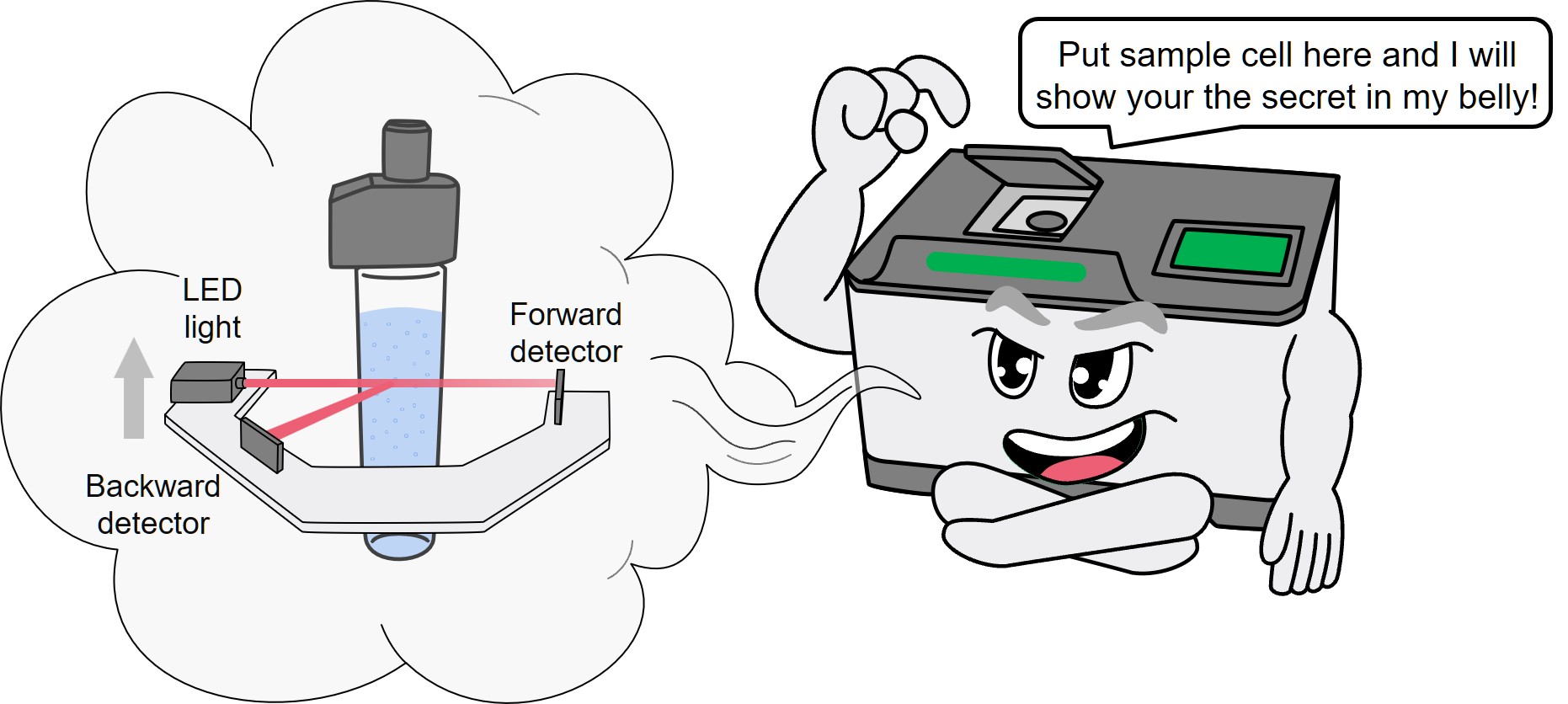

| Laser diffraction-based particle sizing is an ideal analytical technique for cosmetic products. As one of the most widely used particle sizing methods worldwide, laser diffraction applies Mie scattering theory to describe the relationship between particle size and the resulting light scattering patterns. | |

|

The Bettersizer 2600 Plus, a brand-new model in the Bettersizer series, is a high-performance particle size analyzer using laser diffraction. The Bettersizer 2600 Plus features a modular design suitable for various types of samples, an innovative and patented optical system that enhances measurement accuracy and extends the sizing range, as well as high repeatability, reproducibility, and user-friendly operation with simple maintenance and intuitive software.

In addition, the optional imaging module PIC-1 can be integrated into the analyzer to characterize particle shape using dynamic image analysis. This technique is particularly sensitive to coarse particles, thereby compensating for the limitations of laser diffraction in measuring millimeter-scale materials.

The modular design of the Bettersizer 2600 Plus allows seamless switching between different dispersion units for wet and dry measurements.

In cosmetic particle size analysis, dry dispersion measurements are typically used for powder-based products such as loose powders and powder foundations. In contrast, wet dispersion measurement is used for liquid and semi-solid formulations, including sunscreens, BB creams, liquid foundations, and clay masks. This flexibility enables comprehensive particle size characterization across diverse cosmetic formulations using a single analytical platform. |

|

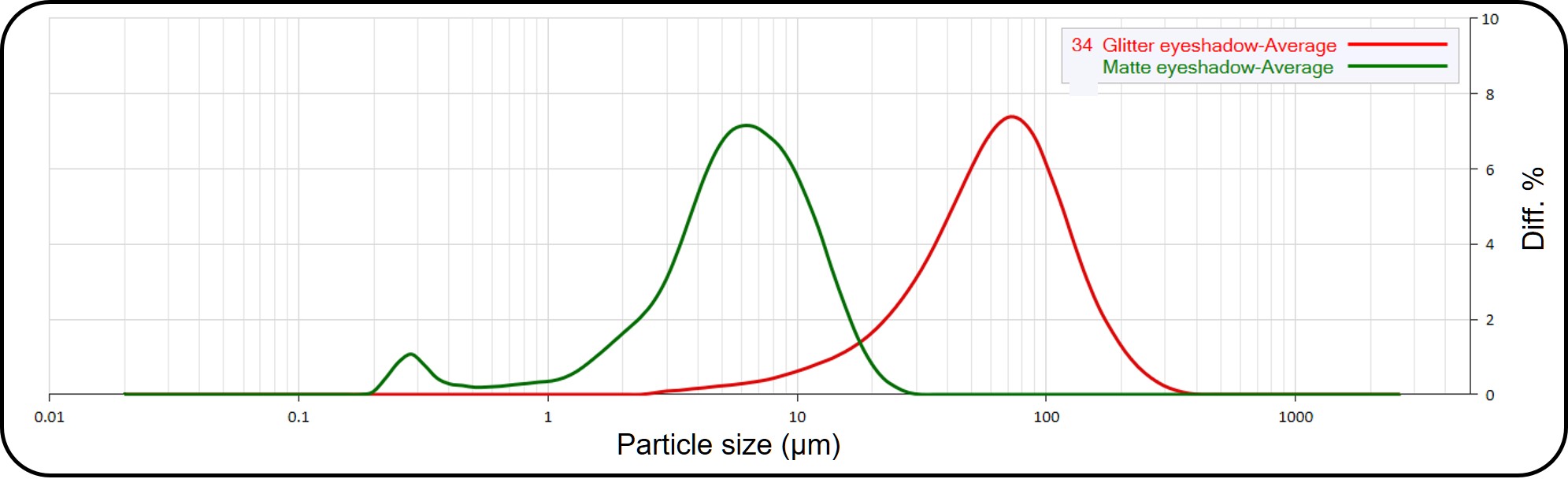

Particle Sizing of Eyeshadow

Two commercially available eyeshadow products were measured using the Bettersizer 2600 Plus. One was a matte eyeshadow, and the other was a glitter eyeshadow. Water was initially selected as the dispersion medium for both samples. However, significant agglomeration was observed when dispersing the matte eyeshadow in water.

To address this issue, the matte eyeshadow sample was subsequently prepared using a surfactant solution containing sodium dodecyl benzene sulfonate (SDBS), which effectively improved particle dispersion. The resulting particle size distributions are presented below.

As expected, the glitter eyeshadow exhibited a generally larger particle size compared with the matte eyeshadow. These differences reflect the distinct functional design and formulation of the two product types. Glitter eyeshadows contain relatively coarse particles, such as glitter flakes or shimmer components, to achieve a sparkling visual effect. In contrast, matte eyeshadows are formulated with finer pigments that provide a smoother texture and more uniform color payoff on the skin.

For further characterization, dynamic image analysis can be employed alongside laser diffraction to directly observe glitter flakes or shimmer particles. Image-based methods enable detailed evaluation of particle shape and can enhance measurement accuracy for coarse or non-spherical particles, providing complementary insights into eyeshadow formulation and performance.

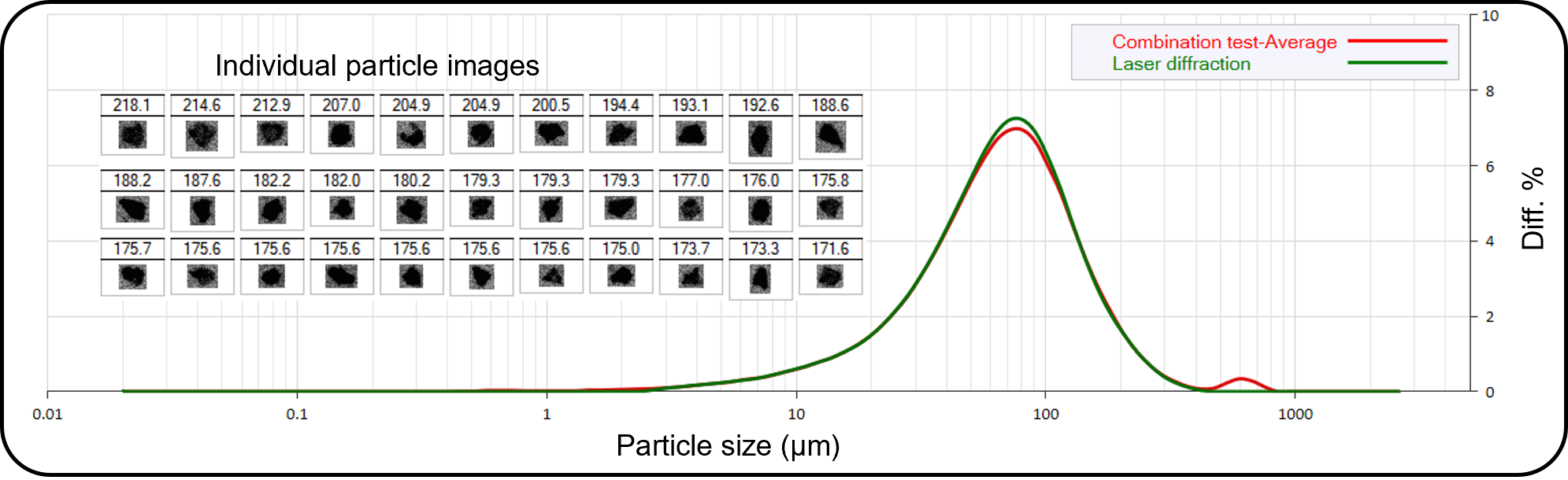

Analyzing Glitter Eyeshadow

by Combining Laser Diffraction and Image Analysis

In laser diffraction-based particle size measurements, the optical system collects the total scattered light signal generated by all particles within the sample. In glitter eyeshadow formulations, glitter flakes typically represent only a small fraction of the total particle population. As a result, the light scattering produced by these coarse glitter flakes is relatively weak and can be easily masked by the stronger scattering contributions from the numerous fine particles. In some cases, the signals from glitter flakes may be incorrectly classified as noise and removed during data processing, leading to an underestimation of particle size.

To overcome this limitation, the imaging module PIC-1 provides a complementary analytical approach. By capturing particle images using cameras, individual glitter flakes can be directly visualized, identified and analyzed.

The combination of laser diffraction and image analysis ensures that information from a small number of coarse particles is not overlooked. This integrated approach improves the accuracy of particle size measurement across a wide size range while providing valuable morphological insights that are particularly relevant for evaluation of the visual performance of glitter-containing cosmetics.

In the particle size distribution results shown below, the red curve represents results obtained by combining laser diffraction and image analysis, while the green curve reflects data generated solely by laser diffraction.

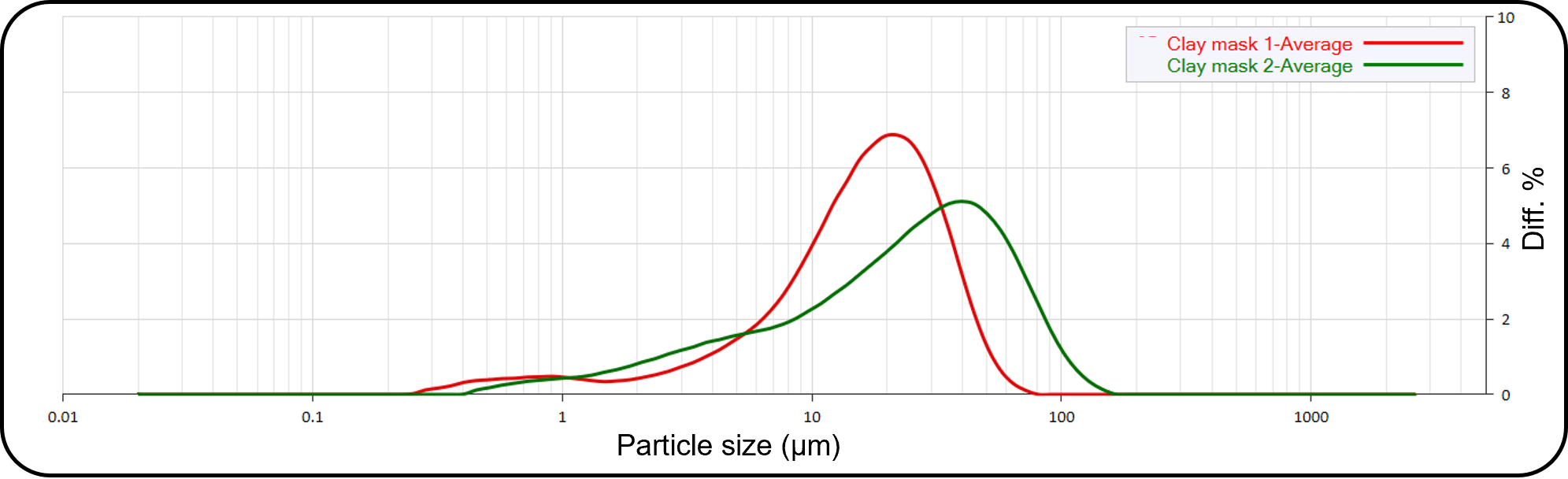

Particle Sizing of Clay Masks

Two commercially available clay mask products were analyzed with the Bettersizer 2600 Plus. The samples were dispersed in ethanol, which served as dispersion medium to ensure good particle wetting and to reduce agglomeration that can occur in water.

The prepared suspensions were then introduced into the BT80N Pro anti-corrosive wet dispersion unit, which is specifically designed for corrosive media or samples and enables fully automated particle size measurements.

The results indicate that clay mask 1 exhibits a smaller particle size than clay mask 2.

|

Qualitative and Quantitative Stability

|

|

|

|

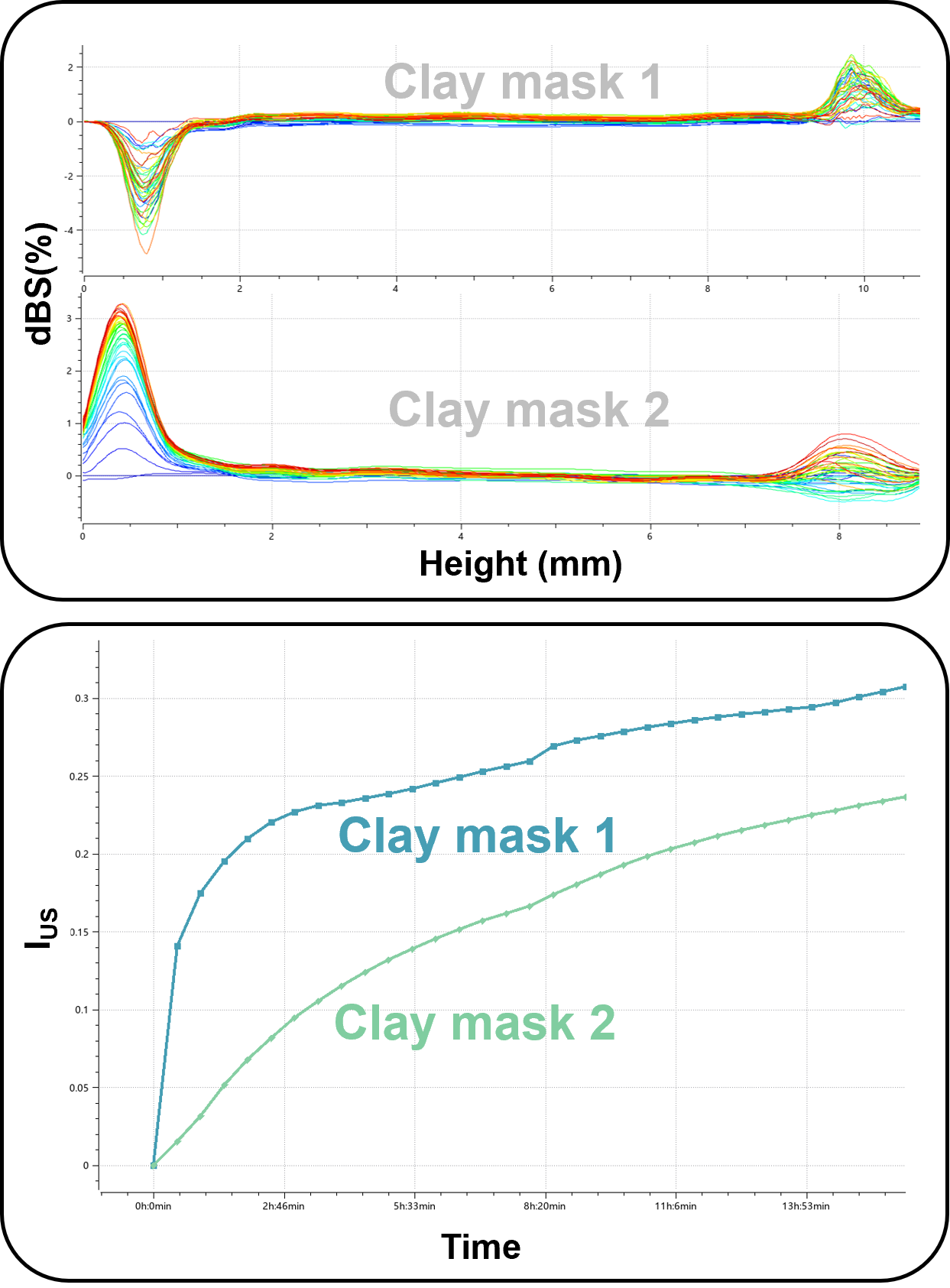

Clay masks are typically formulated as highly concentrated pastes. While particle size underpins initial product performance, dispersion stability is essential for preserving that performance throughout the product’s shelf life. Stability analysis can be effectively conducted using the static multiple light scattering technique (SMLS). |

||

|

This method monitors variations of transmitted and backscattered light intensity as the sample cell is periodically scanned along its vertical axis. Smaller variations in light intensity correspond to a more stable dispersion system. By evaluating both the evolution and magnitude of these changes, SMLS enables qualitative identification of destabilization mechanisms as well as quantitative assessment of dispersion stability.

Because both clay mask samples are opaque, backscattered light signals were used for the stability analysis. From a qualitative perspective, clay mask 1 exhibits creaming behavior. This is evidenced by a decrease in backscattering at the bottom of the sample cell and a corresponding increase at the top, indicating upward migration of particles over time. Additionally, a slight overall increase in backscattering in the middle region suggests changes in particle size within the bulk of the formulation. |

||

|

|

|

In contrast, clay mask 2 shows a pronounced positive peak in backscattering at the bottom of the sample cell, indicating an increasing particle concentration in that region over time. This behavior is characteristic of sedimentation, where particles migrate downwards under the influence of gravity. Variations in backscattering intensity observed in the middle zone imply changes in particle size or structure during storage, suggesting ongoing destabilization processes within the formulation.

Theoretically, dispersions composed of smaller particles generally exhibit higher stability. However, despite having a smaller average particle size, clay mask 1 shows a higher instability index (IUS) value. The IUS is a quantitative parameter used to assess dispersion stability and is calculated from temporal variations in light intensity during measurement time. A higher IUS value indicates greater fluctuations in light intensity and therefore lower dispersion stability. |

|

Dispersion stability is influenced not only by particle size, but also by multiple interacting factors, including interparticle forces, density differences between phases, temperature, and formulation viscosity. As a result, stability evaluation based solely on particle size can be misleading, since overall stability reflects the combined influence of the above-mentioned factors. By integrating particle size measurement with stability evaluation, the BeScan Lab provides a comprehensive and reliable approach for characterizing the stability behavior of dispersed cosmetic systems. |

||

| A Comprehensive Insight into Cosmetic Formulations |

|

|

Laser diffraction is a highly effective technique for particle size analysis in cosmetic applications. The Bettersizer 2600 Plus provides accurate and reliable particle size measurements across a wide range of cosmetic formulations and can be seamless integrated with the PIC-1 dynamic imaging module to extend the measurement range and provide particle shape characterization. This combined analytical approach ensures that even a small proportion of large particles, such as glitter flakes in eyeshadows, are accurately detected and quantified.

Beyond particle size, dispersion stability is a critical quality attribute for paste- and cream-based cosmetics. The SMLS technique enables both qualitative identification of destabilization phenomena and quantitative assessment of dispersion stability over time.

Results obtained from clay mask analysis measurements show that formulation stability is influenced not only by particle size but also by additional factors such as interparticle interactions and formulation properties. Together, the Bettersizer 2600 Plus’s and BeScan Lab’s analytical capabilities provide a comprehensive solution for particle size and stability evaluation, supporting robust cosmetic formulation development, process optimization and quality control. |

|

About the Authors

|

Wenjian Zhou |

Bettersizer 2600 PlusAdvanced Particle Size and Shape Analyzer

|

|

1

Recommended articles

Rate this article