Optimizing the Sintering Density of ITO Targets via High-Resolution Particle Size Analysis

2026-02-17Application Note

Abstract: This application note demonstrates how high-resolution laser diffraction enables precise particle size distribution analysis of ITO powders to optimize packing efficiency, sintering density, and electrical performance of sputtering targets. Using the Bettersizer 2600 Plus, engineered bimodal PSDs can be reliably distinguished from suboptimal distributions, supporting robust quality control and upstream material selection in ITO target manufacturing.

Keywords: Indium Tin Oxide (ITO),Particle Size Distribution (PSD), Sintering density, Sputtering targets, Bimodal particle packing, Laser diffraction, Quality control, Bettersizer 2600 Plus

| Product | Bettersizer 2600 Plus |

| Industry | |

| Sample | Thermally Expandable Alumina Microspheres |

| Measurement Type | Particle Size, Particle Shape |

| Measurement Technology |

Introduction

Indium Tin Oxide (ITO) is a widely used Transparent Conducting Oxide (TCO) material used in the fabrication of flat-panel displays, solar cells, and touch-sensing technologies. The optoelectronic performance of these devices—particularly their high optical transparency and good electrical conductivity—is directly influenced by the microstructure of the sputtered ITO thin films. Research indicates that the grain orientation and density of the ceramic sputtering targets play a decisive role in sputtering efficiency and minimizing the formation of surface nodules on deposited films [1].

A key factor governing target microstructure is the Particle Size Distribution (PSD) of the precursor ITO powder. PSD plays a central role in determining both processing behavior and final product performance, influencing several essential properties, including:

Sintering Behavior: An optimized PSD promotes dense microstructure packing and minimizes residual porosity, which is essential for reducing defect formation during sputtering. Ideal particle packing is achieved when fine particles effectively occupy the interstitial spaces between coarser particles without compromising the overall structural framework[2].

- Coarse Particles provide the primary skeletal structure and mechanical integrity of the pressed target.

- Fine Particles act as a "mortar", filling voids between larger particles and reducing shrinkage porosity during the Hot Isostatic Pressing (HIP) phase[3].

Electrical Conductivity: Efficient particle packing reduces grain boundary density, thereby lowering electrical resistivity and enhancing the conductivity of the sintered target[2].

Phase Homogeneity: A well-balanced PSD supports uniform diffusion of tin ions (Sn4+) into the indium oxide lattice, contributing to consistent phase composition and stable electrical properties.

Despite its importance, accurate PSD characterization of high-density ITO powders remains analytically challenging due to their high refractive index, particle agglomeration, and broad size range. This application note evaluates the Bettersizer 2600 Plus laser diffraction analyzer as a high-resolution, high-fidelity solution for characterizing ITO powder PSD, enabling optimization for packing efficiency, improved sintering performance and enhanced quality control of upstream ceramic precursors.

Experimental Design

To differentiate between "application-ready" ITO grades and suboptimal powder batches, particle size measurements were conducted using the Bettersizer 2600 Plus under controlled and reproducible conditions. Both wet and dry dispersion modules were employed to evaluate dispersion behavior across different material types and to verify the robustness and consistency of the measurement methodology.

Wet dispersion was used for all ITO samples to ensure effective deagglomeration and stable particle suspension during analysis. In addition, both wet and dry dispersion approaches were applied to SnO₂ samples to assess method versatility and to compare dispersion efficiency between measurement modes. Detailed measurement procedures and operating parameters for each sample type are summarized in Table 1 for ITO powders and Table 2 for SnO₂ powders.

Table 1. Measurement Procedure for ITO Samples (Wet Dispersion)

| Procedure Step | Parameter | Value/Condition |

|---|---|---|

| Sample Preparation | Sample amount | 1 - 3 g |

| Pre-test treatment | Pre-dispersion in selected dispersion medium. | |

| Dispersion | Dispersion medium | DI water |

| Circulation speed | 1200 rpm | |

| Ultrasonication | 35W power, measurements performed with continuous ultrasonication | |

| Measurement | Optical model | Mie |

| Particle refractive index (RI) | 1.82 | |

| Particle absorption rate (AR) | 0.1 | |

| Medium RI | 1.333 | |

| Target obscuration range | 10% - 20% | |

| Measurement repetitions | 6 repetitions |

Table.2 Measurement Procedure for SnO2

| Procedure Step | Parameter | Value/Condition |

|---|---|---|

| Sample Preparation | Sample amount | 1 - 3 g |

| Pre-test treatment | Pre-dispersion in selected dispersion medium (wet) / Sample added directly to the funnel of BT-912 using a spoon. | |

| Dispersion (Wet) | Dispersion medium | Deionized (DI) water |

| Circulation speed | 1200 rpm | |

| Ultrasonication | No ultrasonication dispersion | |

| Dispersion (Dry) | Dispersion medium | Air |

| Feeding rate | 11 | |

| Feeding height | 2.1 mm | |

| Dispersion pressure | 0.05 MPa | |

| Measurement | Optical model | Mie |

| Particle refractive index (RI) | 1.512 | |

| Particle absorption rate (AR) | 0.5 | |

| Medium RI | 1 | |

| Target obscuration range | 8% - 15% (wet) / 5 - 10% (dry) | |

| Measurement repetitions | 6 repetitions |

Case Study 1: Comparative Analysis of Packing Efficiency (ITO)

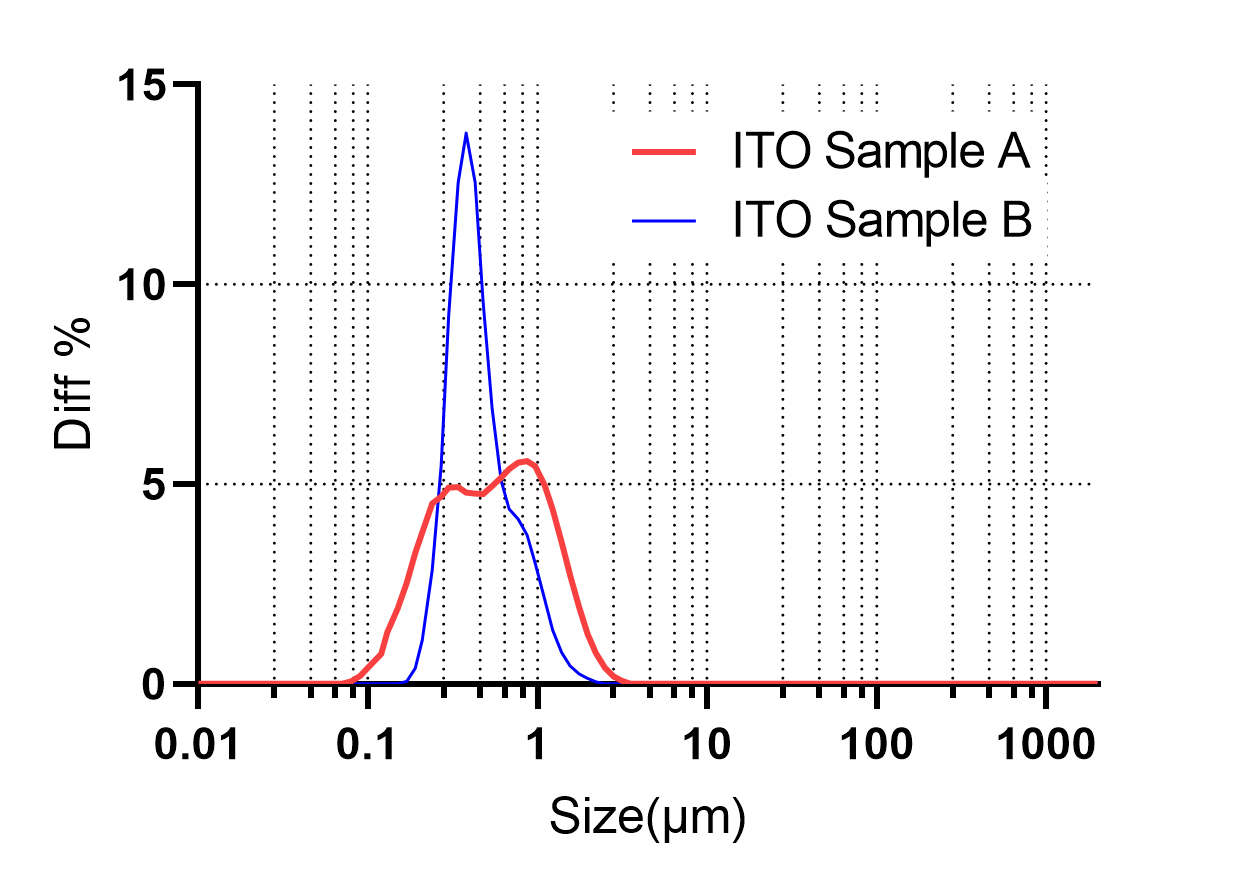

Two sulfide-derived ITO powder samples obtained from the same supplier but processed using different milling routes were evaluated to assess their suitability for fabricating high-density sputtering targets. Although the powders originate from identical raw materials, their milling histories resulted in markedly different particle size distribution (PSD) profiles. As shown in Figure 1, high-resolution particle size analysis using the Bettersizer 2600 Plus reveals distinct structural characteristics that would not be adequately described by conventional summary statistics alone.

Figure 1: Particle Size Distribution Curve of ITO Sample A vs Sample B

Figure 1: Particle Size Distribution Curve of ITO Sample A vs Sample B

Table 3: Key Particle Size Values of ITO Sample A vs Sample B

| D10 (μm) | D50 (μm) | |

|---|---|---|

| Sample A | 0.266 | 0.396 |

| Sample B | 0.184 | 0.508 |

Sample A – Optimized for High Density: Sample A exhibits a distinct Bimodal particle size distribution characterized by a pronounced separation between fine and coarse particle populations. According to the Furnas packing model, this bimodal PSD profile is ideal for ceramic sintering applications; the fine particles fill the interstitial voids formed between the coarse particle structural skeleton [3]. This "Binary-Size" packing arrangement minimizes tortuous pathways for electron transport, maximizes the green body density, and reduces residual porosity after sintering; all of which contribute to improved electrical performance in the final ITO target.

Sample B – Detection of Suboptimal Packing: Although Sample B appears to have more fine particles based on its lower D10 value, its broader PSD and higher D50 and D90 values reflect a Shouldered Distribution rather than a true bimodal profile. The absence of a distinct separation between particle populations limits effective void filling. Particles within the intermediate size range of the "shoulder" region tend to impede close packing by propping open the gaps between larger particles rather than filling the interstitial spaces. This inefficient packing mechanism is associated with increased residual porosity after sintering, which has been correlated with higher electrical resistivity and reduced target performance in sputtering applications [4].

Repeatability Evaluation

To verify the measurement stability and reproducibility of the system, each ITO sample was analyzed six times under identical experimental conditions. The Relative Standard Deviation (RSD) was calculated for key particle size percentiles (D10, D50, and D90) to quantitatively evaluate measurement consistency.

Table 4: Repeatability (%RSD) Across Six Runs

| %RSD10 | %RSD50 | |

|---|---|---|

| Sample A | 0.20 | 0.37 |

| Sample B | 0.28 | 0.98 |

Across all measured percentiles, the system delivered excellent repeatability, with %RSD values significantly below the performance criteria specified in ISO 13320 [6]. These results demonstrated the high measurement stability of the Bettersizer 2600 Plus and confirm its suitability for robust particle size characterization, even under stringent process control and quality assurance requirements.

Case Study 2: Upstream Quality Control (SnO2)

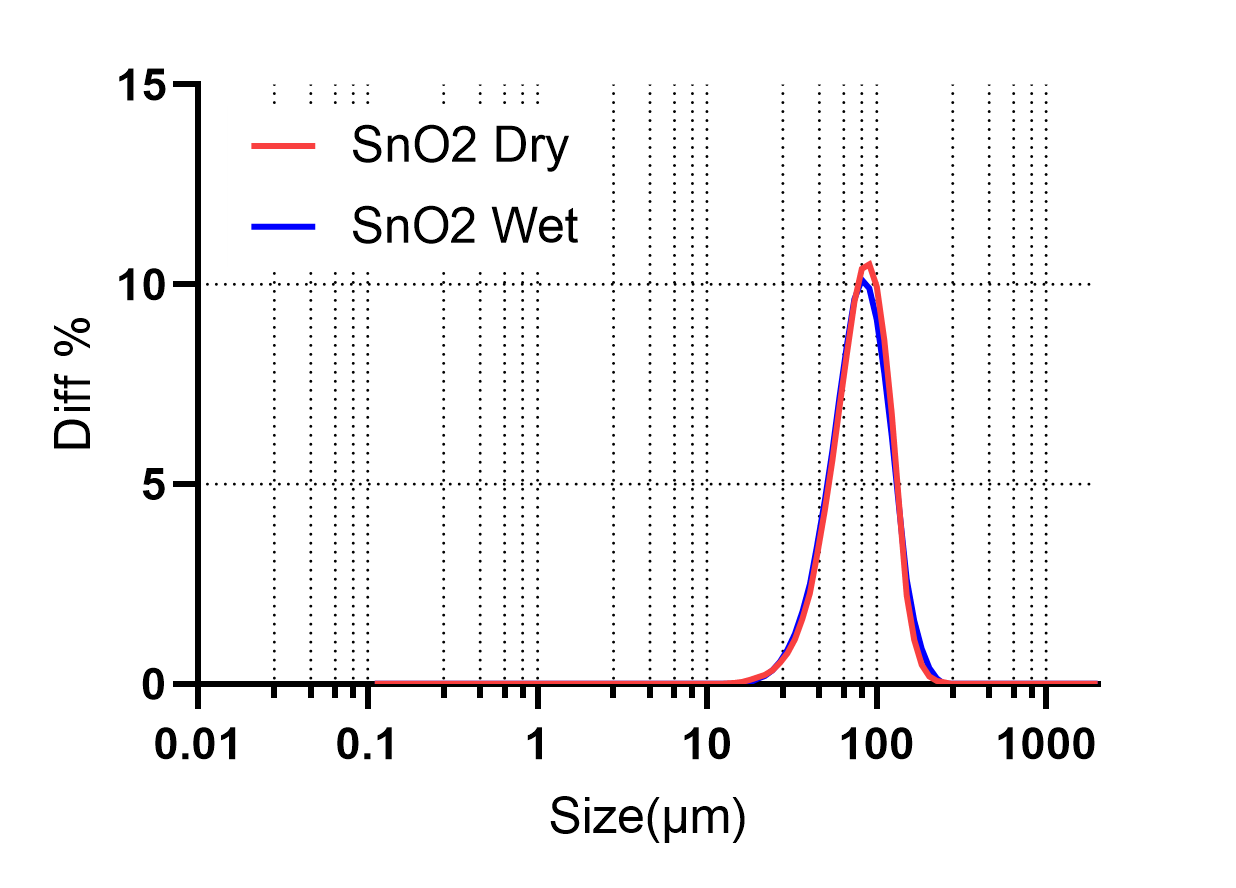

To ensure supply - chain robustness and minimize downstream processing risks, raw Tin Oxide (SnO2) precursor powders were evaluated using both wet and dry dispersion techniques. The objective of this study was to validate a fast, high-throughput dry dispersion method suitable for routine incoming quality control, while ensuring equivalence with established wet dispersion measurements.

Figure 2: Particle size distribution curve of SnO2 wet method vs dry method

As shown in Figure 2, the particle size distribution obtained using dry dispersion (Red curve) closely matches that measured by the Wet dispersion method (Blue curve) across the entire dynamic range. The primary distribution peaks are well aligned, and the overall distribution widths (Span values) are nearly identical. This strong agreement confirms that the pneumatic shear forces generated by the Venturi nozzle in the dry dispersion system are sufficient to overcome the Van der Waals forces responsible for agglomeration in SnO2 powder. Consequently, a dispersion state equivalent to that achieved through the liquid-based agitation method is obtained.

Table 5: Cross Method Reliabiliy

| D10 (μm) | D50 (μm) | |

|---|---|---|

| Wet Method | 43.10 | 76.53 |

| Dry Method | 43.82 | 77.72 |

| Relative Differences* % | 1.67 | 1.55 |

*Relative differences calculated with respect to wet-method results.

The results demonstrate excellent correlation between the two dispersion methods, with relative differences below 3% for all key particle reported percentiles. This level of agreement validates the dry dispersion method as a reliable option for routine quality control measurements. By adopting dry dispersion for incoming inspection, quality control laboratories can significantly increase throughput and operational efficiency while maintaining data integrity. Importantly, this approach allows manufacturers to identify substandard precursor batches before they enter the costly compounding and solid-state diffusion stages, thereby reducing waste and preventing defects in downstream ITO target production [5].

Repeatability Evaluation

To assess the stabilit y and reproducibilit y of the measurement system, SnO2 samples were analyzed six consecutive times, using both wet and dry dispersion methods. Measurement repeatability was quantified by calculating the Relative Standard Deviation (RSD) for key particle size percentiles (D10, D50, and D90).

Table 6: SnO2 Repeatability Statistics

| %RSD D10 | %RSD D50 (μm) | |

|---|---|---|

| Wet Method | 0.266 | 0.396 |

| Dry Method | 0.184 | 0.508 |

The results demonstrate excellent repeatability for both dispersion methods. All RSD values are significantly below the requirements specified by ISO 13320 [6], confirming that the Bettersizer 2600 Plus delivers the data integrity and measurement stability necessary for stringent process control and quality assurance applications.

Case Study 2: Upstream Quality Control (SnO2)

The successful fabrication of high-performance sputtering targets requires rigorous, high-fidelity characterization of raw powder microstructures. Integrating the Bettersizer 2600 Plus into the quality control and research workflows provides a comprehensive analytical solution that enables informed decision-making across the production chain.

First, the system delivers deep insight into powder structure by accurately distinguishing engineered bimodal ITO grades – optimized for high-density sintering – from Shouldered distributions that compromise packing efficiency. The level of detail reveals critical structural deficiencies that cannot be detected through conventional single-value metrics such as D50 alone.

Second, the validation of a high-throughput Dry Dispersion method for SnO₂ precursors significantly improves operational efficiency in upstream quality control. This approach allows rapid screening of incoming materials, strengthening supply-chain robustness while reducing processing time and cost.

Finally, the instrument provides highly repeatable PSD measurements, with RSD values well below 0.2% for key percentiles. This exceptional repeatability supports reliable batch-to-batch consistency, reduces variability during sintering, and minimizes yield loss in furnace operations.

Together, these capabilities establish the Bettersizer 2600 Plus as a powerful tool for optimizing material selection, ensuring process stability, and delivering consistent performance in sputtering target manufacturing.

References

[1] F. Mei et al., "Microstructure evolution and grain orientation in ITO targets and their effects on the film characteristics," J. Mater. Sci. Mater. Electron., vol. 29, no. 17, pp. 14620–14634, 2018.

[2] X. Zhai, Y. Chen, Y. Ma, S. Sun, and J. Liu, "A new strategy of binary-size particles model for fabricating fine grain, high density and low resistivity ITO target," Ceram. Int., vol. 46, pp. 13660–13668, 2020.

[3] A. S. Helle, K. E. Easterling, and M. F. Ashby, "Hotisostatic pressing diagrams: new developments," Acta Metall., vol. 33, pp. 2163–2174, 1985.

[4] T. Liu, Z. Jiang, X. Zhai, and J. Liu, "Effect of particle composition on microstructure and resistivity of indium tin oxide targets," Chem. Phys. Lett., vol. 801, Art. no. 139743, 2022.

[5] N. Nadaud et al., "Structural Studies of Tin-Doped Indium Oxide (ITO) and In4Sn3O12," J. Solid State Chem., vol. 135, no. 1, pp. 140–148, 1998.

[6] Particle size analysis – Laser diffraction methods, ISO 13320:2020, International Organization for Standardization, 2020.

About the Authors

|

Weichen Gan |

Recommended articles

Rate this article