Characterization of Moisture-Sensitive Solid Electrolytes Using Inert-Atmosphere Laser Diffraction

2026-02-17Application Note

Abstract: Particle size distribution (PSD) is a critical quality attribute for moisture-sensitive solid electrolytes used in all-solid-state batteries, directly affecting sintering behavior, ionic conductivity, and interfacial contact. This study demonstrates inert-atmosphere laser diffraction for safe and accurate PSD characterization of sulfide and halide solid electrolytes, enabling reliable grade differentiation and robust quality control under oxygen- and moisture-free conditions.

Keywords: Solid electrolytes, Particle size distribution (PSD), All-solid-state batteries (ASSBs), Laser diffraction, Inert atmosphere measurement, Moisture-sensitive materials

| Product | Bettersizer 2600 Plus |

| Industry | |

| Sample | Moisture-sensitive solid electrolytes (sulfide and halide electrolytes) |

| Measurement Type | Particle Size |

| Measurement Technology |

Introduction

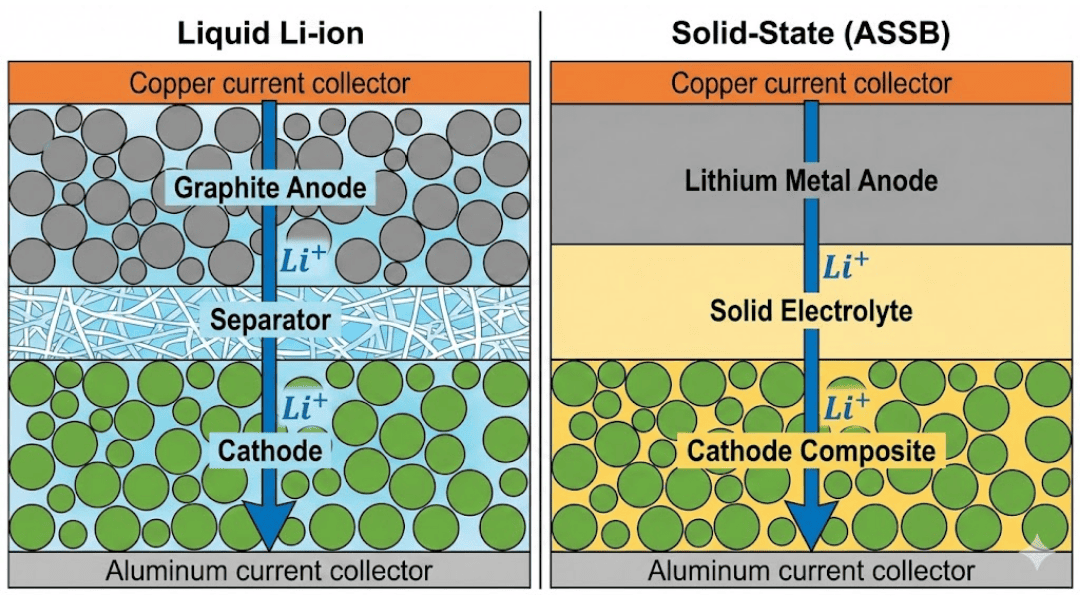

The transition from liquid or gel electrolytes used in Lithiumion batteries (LIB) to solid electrolytes in All-Solid-State Batteries (ASSBs) represents a pivotal evolution in battery technology, promising superior safety, energy density, and longevity by using a solid instead of a liquid electrolyte. The performance of an ASSB, however, is intrinsically linked to the physical properties of the solid-state electrolyte (SSE). Among these, the Particle Size Distribution (PSD) plays a central role in determining key critical quality attributes (CQAs), such as:

- Sintering Behavior: Optimized particle sizes promote dense microstructures and reduce residual porosity.

- Ionic Conductivity: Well-packed particles minimize tortuous pathways for ion transport.

- Interfacial Contact: A balanced distribution helps reduce interfacial impedance between the electrode and electrolyte layers.

Despite the importance of PSD, accurately characterizing high-performance sulfide and halide electrolytes presents a substantial analytical challenge. These materials exhibit extreme hygroscopicity; even brief exposure to ambient moisture can trigger rapid hydrolysis, generating hazardous gases such as H(2)S and causing artificial agglomeration that distorts particle size results. This application note evaluates a specialized measurement approach—the Bettersizer 2600 Plus particle size analyzer integrated directly into an inert-atmosphere glovebox—to ensure safe, accurate, and reproducible PSD characterization of highly reactive solid electrolyte battery materials used in nextgeneration ASSB development.

Figure 1: Conventional lithium-ion battery versus ASSB structure

Experimental Setup: The Inert Environment Solution

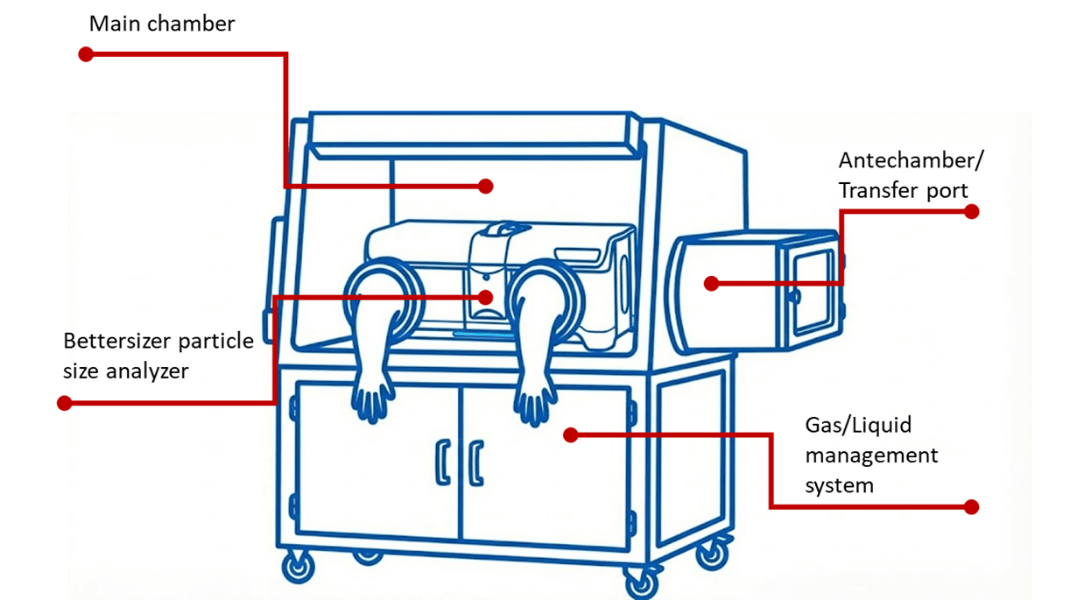

To prevent environmental contamination and ensure accurate measurement of moisture-sensitive electrolytes, a Bettersizer 2600 Plus Laser Diffraction Analyzer was installed inside a custom-engineered inert-atmosphere glovebox, as shown in Figure 2. This integrated system provides complete isolation from ambient air and enables safe, reproducible PSD analysis under controlled conditions.

Figure 2: Diagram of the inert-atmosphere glovebox system with the Bettersize instrument

General System Features

The glovebox and instrument installation incorporate the following capabilities:

● Fully Inert gas atmosphere (He, N2, Ar), with O2 and H2O levels maintained below 1 ppm.

● Active pressure management to maintain stable internal operating conditions.

● Airtight feedthrough ports for electrical connections, control cables, and gas/liquid lines.

● Corrosion-resistant internal surfaces to ensure long-term compatibility with reactive materials

Dry Dispersion System Features

For dry-powder characterization, the system includes:

- A compressed inertgas dispersion source to prevent moisture exposure during dry powder dispersion

- Two integrated dust collection systems:

- One dedicated to capturing airborne particulates within the glovebox

- One for collecting residual sample material after testing - Real-time visual monitoring via a viewing window integrated into the dust-collection tank.

Wet Dispersion System Features

For wet-dispersion analysis, the system includes:

● A built-in liquid waste collection and recovery system supports safe handling of test media

● Use of a low-moisture liquid medium (<1% water content) minimizes hydrolysis risk and prevents artificial agglomeration during measurement.

Measuring Sulfide Samples PSD via Wet Dispersion

Three sulfide electrolyte samples, sourced from different application processes within the same manufacturing line, were analyzed using the Bettersizer 2600 Plus equipped with a BT-812 automatic wet dispersion unit accessory integrated within the inert-atmosphere glovebox described above. A BT812 automatic wet dispersion unit was employed to prevent moisture-induced degradation and to ensure stable particle separation during measurement. Table 1 summarizes the measurement procedure used for all sulfide samples.

Table 1: Measuring Procedure for Sulfide Samples

| Procedure Step | Parameter | Value/Condition |

| Sample Preparation |

Sample amount | 0.5 mL |

| Pre-test treatment | Pre-dispersion in selected dispersion medium. | |

| Dispersion | Circulation speed | n-heptane |

| Ultrasonication | 1200 rpm | |

| Ultrasonication | 35W power, 120s duration, measurements performed with applied ultrasonication | |

| Measurement | Optical model | Mie |

| Particle refractive index (RI) | 1.52 | |

| Particle absorption rate (AR) | 0.1 | |

| Medium RI | 1 | |

| Target obscuration range | 8% - 11% | |

| Measurement repetitions | 6 repetitions |

Each sample was measured six times to evaluate repeatability, and the relative standard deviation (RSD) was calculated to quantify the consistency and stability of the results.

Measuring PSD of Halide Samples Using Dry Dispersion

Three halide samples from different manufacturers were measured using the Bettersizer 2600 Plus particle size analyzer with the glove box setup, as discussed above, and a BT-912 automatic dry dispersion unit. The measuring procedure is shown in Table 2.

Table 2: Measuring Procedure of Halide Samples

| Procedure Step | Parameter | Value/Condition |

| Sample Preparation | Sample Amount | 2 - 5 g |

| Pre-test Treatment | None; sample added directly to the funnel of BT-912 using a spoon. | |

| Dispersion | Feeding Rate | 11 |

| Feeding Height | 2.1 mm | |

| Dispersion Pressure | 0.4 MPa | |

| Dispersion Medium | Nitrogen | |

| Measurement | Optical Model | Mie |

| Refractive Index (RI, particle) | 1.52 | |

| Absorption rate (AR, particle) | 0.1 | |

| RI (medium) | 1 | |

| Target Obscuration Range | 5% - 10% | |

| Measurement Repetitions | 6 repetitions |

Each sample was measured six times to evaluate repeatability, and the relative standard deviation (RSD) was calculated to assess the stability and consistency of the PSD results.

Results and Discussion

CASE STUDY 1

Sulfide Electrolytes (Wet Dispersion)

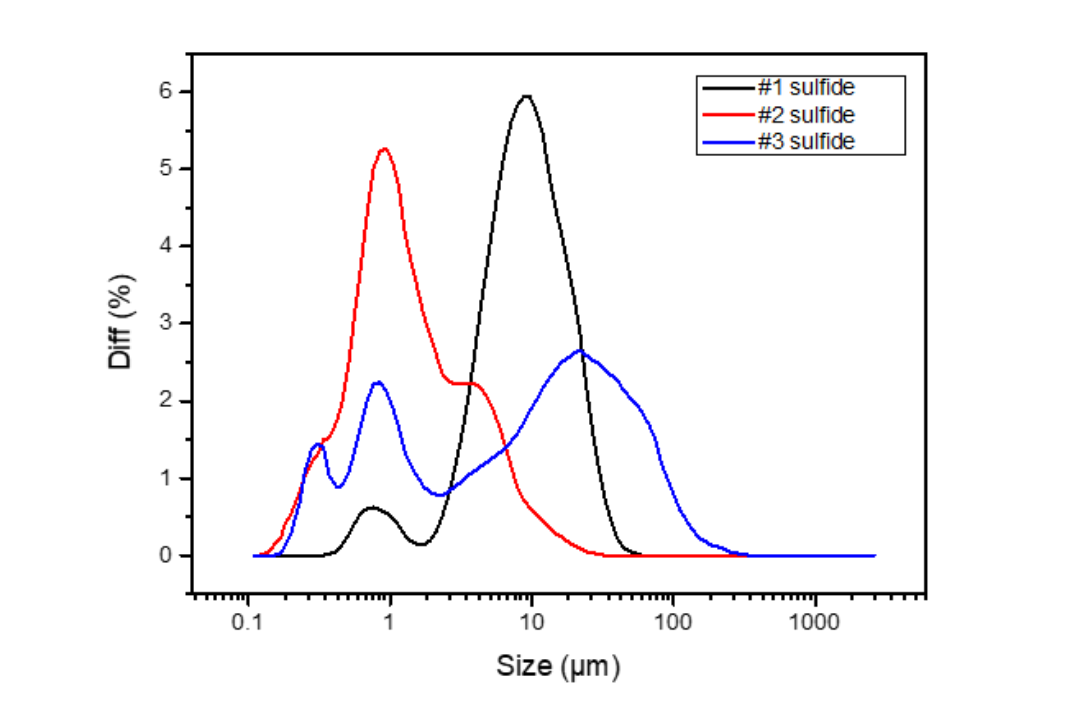

Three sulfide electrolyte samples from different production processes were analyzed to assess their suitability for various battery-cell layers. As illustrated in Figure 3 and summarized in Table 3, the Bettersizer 2600 Plus measurements revealed distinct particle size distributions and structural characteristics for Samples #1, #2, and #3.

Figure 3: Particle size distribution of the three sulfide samples

Table 3: D10, D50 and D90 values of the three sulfide samples

| Stage | D10 (LD, µm) | D50 (LD, µm) | D90 (LD, µm) |

| #1 sulfide | 3.205 | 8.350 | 19.23 |

| #2 sulfide | 0.404 | 1.111 | 4,930 |

| #3 sulfide | 0.496 | 9.711 | 54.96 |

The high-resolution optics of the Bettersizer 2600 Plus revealed clear differentiation between the samples, including significant structural differences that would not be captured by basic statistical metrics alone.

Interpretation of PSD Differences

- Sample #1 – Suitable for Separator Applications: Sample #1 exhibits a relatively coarse and uniform distribution (D50 ~ 8.4 μm) with minimal fines (D10>3 μm). This profile is suitable for a bulk separator layer where larger grains help reduce grain-boundary density, potentially improving intrinsic ionic conductivity and enhancing flowability during manufacturing.

- Sample #2 – Optimized for Cathode Composites: Sample #2 features a much finer, tightly distributed PSD (D50 ~ 1.1 μm), resulting in a highly specific surface area. This enables intimate contact with cathode active materials (e.g., NCM, LFP), supporting reduced interfacial impedance and improving electrochemical performance.

- Sample #3 – Detection of a Problematic Batch: Although Sample#3 shares a similar median size to Sample #1. Its PSD reveals a significant "coarse tail" extending beyond 50 μm. In a typical 30–50 μm solid electrolyte layer, these large particles create mechanical stress points and may puncture the electrolyte, posing a risk of short circuit. Identifying this "failed batch" despite the same chemistry of Sample #1 is critical for Quality Control and batch acceptance.

Repeatability Evaluation

To verify the robustness of the measurements of the Bettersizer 2600 Plus within the inert-atmosphere glovebox environment, each sulfide sample was analyzed six times, and the Relative Standard Deviation (RSD) was calculated for D10, D50, and D90.

Table 4: Repeatability (%RSD) Across Six Runs

| %RSD D10 | %RSD D50 | %RSD D90 | |

| #1 sulfide | 1.24 | 0.95 | 1.86 |

| #2 sulfide | 0.69 | 0.67 | 0.98 |

| #3 sulfide | 0.24 | 0.55 | 0.67 |

Despite the operational complexity of performing PSD analysis within an oxygen- and moisture-free glovebox, handling anhydrous solvents and pressurized inert gas, the Bettersizer 2600 Plus delivered RSD values below 2% across all size metrics. This exceeds the repeatability requirements of ISO 13320, which typically permits 3-5% variation, proving that glovebox integration does not compromise data accuracy or measurement stability.

CASE STUDY 2

Halide Electrolytes (Dry Dispersion)

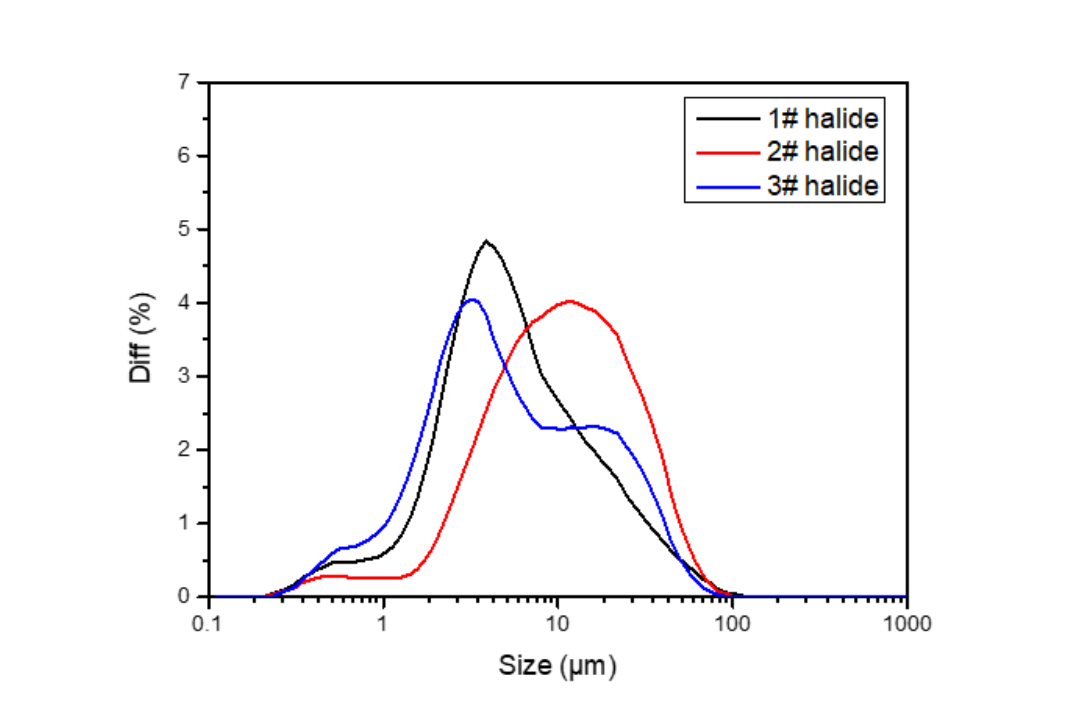

Three commercial halide electrolyte materialsfrom different supplierswere evaluated to benchmark variability in synthesis quality and PSD control across the market. Results are shown in Figure 4 (PSD curves) and Table 5 (key particle size values).

Figure 4: Particle size distribution of the three halide samples

Table 5: D10, D50, and D90 values of the three halide samples

| D10 (LD, µm) | D50 (LD, µm) | D90 (LD, µm) | |

| #1 halide | 1.584 | 4.726 | 20.55 |

| #2 halide | 2.719 | 9.874 | 30.54 |

| #3 halide | 1.093 | 3.888 | 22.58 |

Benchmarking Supplier Variability

Analysis of the PSD curves and characteristic size values reveals notable differences in product consistency among the suppliers:

Stable, Controlled Production (Samples #1 and #2): Samples from Supplier A and Supplier B exhibit clean, unimodal PSDs.

- Supplier A provides a fine-grade electrolyte (D50 ~ 4.7 um)

- Supplier B offers a coarse grade (D50 ~ 9.9um)

In both cases, the distributions are smooth and well-controlled, indicating stable synthesis methods and consistent milling or crystallization processes.

Quality Risk Identified (Sample #3): While the statistical values for Sample #3 appear similar to those of Sample #1. The full PSD curve (Figure 4) reveals a pronounced "shoulder" defect, indicating the presence of a secondary mode. This bimodal distribution suggests instability in Supplier C's process. Potential issues may include inconsistent milling, inadequate mixing, or uncontrolled crystallization.

Such variability introduces risk for battery manufacturers, particularly in applications requiring high uniform particle packing. In this context, Sample #3 would be classified as a “Grade B” material compared to the more tightly controlled products from Suppliers A and B.

Repeatability Assessment

Repeatability was evaluated by measuring each halide sample six-times under dry dispersion conditions. The Relative Standard Deviation (RSD) for D10, D50, and D90 was calculated to assess analytical precision.

Table 6: Repeatability% (RSD) Across Six Runs for Halide Samples

| %RSD D10 | %RSD D50 | %RSD D90 | |

| #1 halide | 0.13 | 1.05 | 0.88 |

| #2 halide | 0.01 | 0.04 | 0.07 |

| #3 halide | 0.08 | 0.48 | 0.02 |

Across all three samples, the dry-dispersion measurements produced RSD values consistently ≤1.0%, demonstrating excellent repeatability. These results confirm:

- The high mechanical stability of the BT-912 dry-dispersion system,

- The precision of the Bettersizer 2600 Plus optical performance

- The effectiveness of the glovebox environment in maintaining stable, contamination-free measurement conditions.

Even with operational complexities such as purge cycles and handling of reactive materials, the system significantly outperformed the repeatability requirement of ISO 13320, which typically specifies allowable variation of <3%. This confirms that inert-tmosphere isolation introduces no compromise to data integrity.

Conclusion

Commercializing All-Solid-State Batteries (ASSBs) demands rigorous control over moisture-sensitive electrolytes. The Bettersizer 2600 Plus Glovebox System secures this critical step, delivering advanced laser diffraction analysis within a fully protected inert environment. This integrated approach delivers three key advantages:

1. Safety: Ensures full protection for both operators and sensitive materials by preventing hydrolysis and suppressing hazardous gas generation (e.g., H2S).

2. Insight: Enables precise differentiation between application-specific electrolyte grades (e.g., cathode-compatible vs. separator-compatible) and reveals hidden structural defects such as agglomerates or secondary peaks.

3. Control: Provides highly repeatable PSD measurements (<1% RSD) supporting reliable high-throughput quality control and ensuring consistent batch-to-batch performance.

By adopting this integrated glovebox-laser diffraction system, manufacturers can strengthen their supply chain robustness, ensure electrolyte uniformity, and optimize electrochemical performance, accelerating the deployment of safer, higher-energy density solid-state battery technologies.

About the Authors

|

Zhichao Han |

|

Weichen Gan |

Recommended articles

Rate this article