Application of Laser Particle Size Analyzer in Coffee

2021-07-23Application Note

This note examines how coffee grinding method, particle size, and particle size distribution affect coffee quality, and presents optimization methods and principles. Results demonstrate that laser particle size analyzers effectively monitor grinding processes, ensuring product homogeneity and improving coffee quality while supporting quality control in grinding equipment development and production.

| Product | Bettersizer 2600 |

| Industry | Food and Drink Analysis |

| Sample | Coffee |

| Measurement Type | Particle Size |

| Measurement Technology | Laser Diffraction |

Jump to a section:

Abstract: This paper explores the effects of coffee grinding method, particle size and its distribution on coffee quality, and introduces the measurement methods and principles for optimizing coffee particle size and its distribution. Laser diffraction particle size analyzer is widely used in particle size industry due to its unique advantages. The study results show that the laser diffraction particle size analyzer can effectively analyze and monitor the particle size and its distribution of the coffee in the grinding process, ensuring the homogeneity of the product and improving the quality of the coffee and also contributing to quality control in the development and production of coffee grinding equipment, whether it is coarse grinding or fine grinding. Bettersizer 2600 adopts a negative pressure parallel suction dispersion structure to avoid the blockage of the sample, thus ensuring the continuity and reliability of the particle size measurement process.

Keywords: coffee, particle size distribution, laser diffraction particle size analyzer

Grinding process is a crucial step in making coffee. The size of the ground coffee is related to the choice of extraction methods, the speed of fluid, and the taste and flavor of coffee. In general, the extraction (brewing) method of coffee determines the size of the coffee grinding, the coffee powder must be ground to the appropriate size to increase the area of contact between the hot water and the coffee powder, so the aroma substance contained in coffee can be completely extracted. The longer the extraction time, the less contact area is needed, the coarser the coffee beans are, avoiding bitterness. The shorter the extraction time, the more contact area is needed, the more the coffee beans are ground, avoiding the light taste. For example, the drip coffee machine and the French pressure pot are suitable for coarse grinding coffee powder, the siphon pot and the soaking coffee extraction pot are suitable for medium coarse powder, the moka pot is more suitable for medium fine coffee powder, the American drip pot and the pressure pot need fine powder, while the Italian brewer needs the finest coffee powder. It is important not only to adjust the particle size of the coffee powder, but also to control the overall uniformity of the grinding.

If the particle size distribution of the coffee powder is not uniform, the dissolved components are unstable, the brewing time cannot be accurately grasped, the coffee taste is not harmonious, and the taste is different, for example, ordinary flat-plate grinder has poor uniformity of particles and a high content of fine powder. The ghost tooth flat grinding machine has a more uniform grinding effect, so the coffee flavor is more stereoscopic and plentiful.

Therefore, the particle size and its distribution of coffee powder are all indispensable factors affecting the grinding process and coffee quality. During the grinding process of coffee beans, the contact area of coffee powder and air will increase. When the coffee powder is exposed to the air for a long time, the coffee oil will be oxidized by air to produce rancid taste. At the same time, the grinding heat will also cause the coffee powder to lose the original aroma. Therefore, the optimum time for grinding the coffee beans is before grinding, and the lower the temperature produced by the grinding, the better the quality of the coffee.

However, the importance of coffee grain size is often neglected. Therefore, this paper mainly explores the effects of coffee grinding methods, particle size distribution on coffee quality and introduce the related measurement methods to optimize coffee particle size. There are many different methods for testing the powder particle size. The traditional methods mainly include sieving, microscopy, sedimentation method, Coulter, light-blockage etc. However, the traditional sieve method can’t meet the monitoring of particle size and its distribution of the grinding process. The laser diffraction particle size analyzer is widely used in particle size industry due to its unique advantages: fast test, low measurement limit, wide measurement range, good reproducibility, high sensitivity and resolution. This paper focuses on the principle of laser diffraction particle size analyzer and its application research based on the international standard ISO 13320 of laser diffraction particle size analyzer in the measurement of coffee particle size.

1. Principle

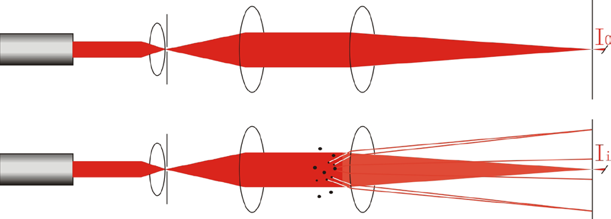

A laser beam emitted by the laser becomes a parallel beam after filtering, expanding, and quasi value. When no particles are illuminated, the parallel beam passes through the Fourier lens and converges on the focal plane to form a small, bright spot-focal point. When the parallel laser beam meets particles, the particles will cause the laser to scatter and some of the light will scatter outwards at an Angle with the optical axis, as shown in the Fig 1.

It has been demonstrated by both theory and experiments that the scattering angle is small for large particle and the scattering angle is large for small particle. The scattered light from different angles will form a series of rings on the focal plane after passing through the Fourier lens. The bright and dark alternate light spots made up of these rings are called Airy plaques. Airy plaques contain rich particle size information. Simply speaking, the light circles with larger radius correspond to smaller particles, and the light circles with smaller radius correspond to larger particles; the light intensity at Airy plaques indicates the number or content of the particles. Thus, a serial of photoelectrical detectors can be installed at the focal plane, which translates light signals to electric signals and input into a computer. Particle size distribution can then be obtained based on Mie scattering theory and inverse algorithm.

2. Experiment

2.1 Instruments

Bettersizer 2600 laser particle size analyzer (Bettersize Instrument Ltd), Silent oil free air compressor (Jiangsu Dynamic Medical Technology Co., Ltd), IVC Series Industrial Vacuum Dust Collector (Yantai Aiweike Dedusting Equipment Co., Ltd), Filter (SMC (China) Co., Ltd), Electric coffee grinder (Dongguan Lianli Electric Industrial Co., Ltd.)

2.2 Sample and reagent

Raw material coffee (domestic company) and purified air

3. Measurement and results

Since coffee is susceptible to physicochemical reactions inconventional medium water, this study only considers the drymethod for particle size measurement.

3.1 Pressure titration

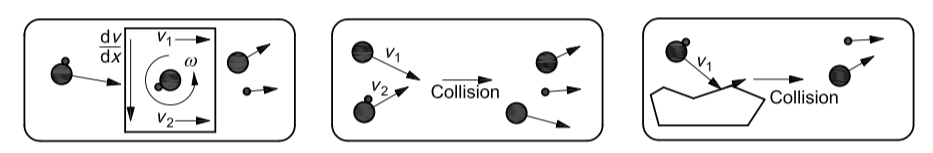

The dry measurement mainly uses the compressed air to transport the particles, and the powder particles are dispersed by the collision of the particles and the particles, the collision of the particles and the pipe wall, and the airflow shear. Under the large shear pressure and collision, it is possible to cause the "crushing" of the coffee particles. In order to ensure the dispersal of large agglomerate without breaking the original particles, the ISO 13320 requires investigating the effect of different dispersive intensity on measurement results.

Usually upon increasing the dispersing energy the amount of fines is increased at first, due to improved dispersion, until a plateau is reached, where the size distribution is nearly constant with increasing energy. At still higher energies the amount of fines may rise again as a result of comminution. On some occasions, agglomeration has been found at high flow rates through a cascade. Its centre defines the optimum dispersing energy (ISO 13320-2009).

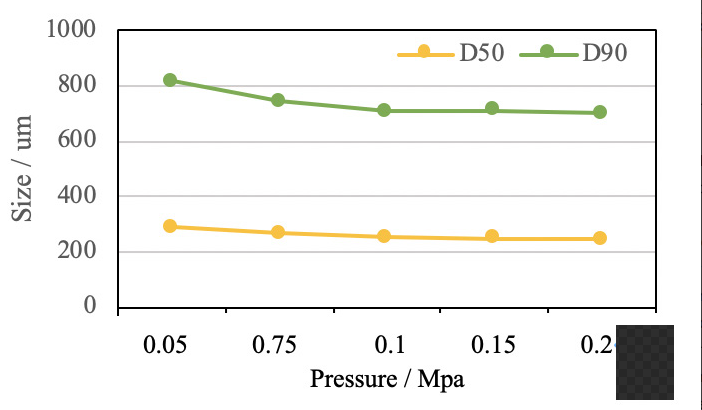

In this experiment, the effects of different pressures on PSD particle size distribution were studied. The results show that D50 and D90 are gradually decreased in the initial stage from 0.05 to 0.1MPa, which means that the agglomerated particles are gradually dispersed with the pressure; The distributions tend of D50 and D90 are stable from 0.1 to 0.15MPa, indicating that the sample is fully dispersed in this pressure range. In the initial stage, the degree of change of D90 with the pressure is significantly higher than D50, which means that the agglomerated particles mainly exist in the coarse end. For some special sample, D97 may need to be investigated in the pressure titration study to avoid the D90 change trend is not obvious enough to lead to wrong analysis.

3.2 Particle size distribution

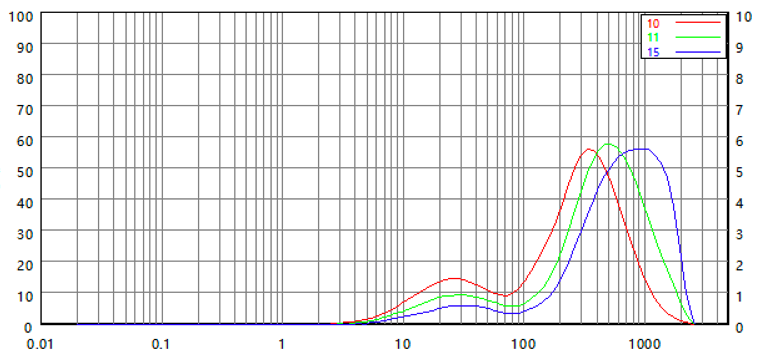

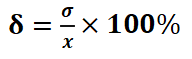

Using the same electric coffee grinder, the same type of coffee beans is ground in 4th, 10th, and 16th grade under the condition of the obscuration of 5-10%, the optical parameters of 1.52-0.1, and the dispersion pressure of

0.15MPa. The coffee particle size of different specification is shown in Figure 4, which shows that Bettersizer 2600 can effectively distinguish the particle size distribution of coffee powder under different grinding efficiency, as a reliable research method for monitoring and controlling particle size distribution. Fine coffee powder is suitable for espresso coffee, and coarse coffee powder is more suitable for filter coffee.

| Number | Grind Rate |

D10/um

|

D50/um | D90/um |

| 10 | Lever 4 | 29.42 | 250.7 | 706.4 |

| 11 | Level 10 | 37.18 | 430.3 | 1096 |

| 15 | Level 16 | 119.1 | 639.9 | 1516 |

3.3 Repeatability

Repeatability is the deviation between the results obtained from multiple measurements of the same sample under the same conditions. The conditions for repeatability tests include the same measurement process, the same operator, the same parameters, the same place, the same instrument, and multiple measurements within a short period. Repeatability is the main criterion to evaluate the reliability of the instrument and the measuring method. The repeatability error is calculated as following:

where n is the number of measurements (usually n ≥ 10); xi is the result of each measurement; x is the average value of the measurements; σ is the standard deviation.

The repeatability is:

(1)

(1)

Under condition of RI 1.52-0.1, air pressure 0.15MPa, obscuration 7%, lever 4, the repeatability of coffee particle size distribution meets the required of ISO 13320 that repeatability errors for laser diffraction instruments are D10 ≤ 5%, D90 ≤ 5%, D50 ≤ 3%. If the particles are smaller than 10 μm or wide distribution, the allowed repeatability errors may be doubled.

(2)

(2)

| Number | D10 / um | D50 / um | D90 / um |

| 20 | 30.54 | 241.8 | 627.2 |

| 22 | 30.10 | 239.3 | 587.0 |

| 27 | 31.32 | 245.9 | 613.5 |

| 30 | 30.74 | 250.2 | 628.5 |

| 35 | 27.51 | 250.6 | 682.3 |

| RSD | 4.93% | 2.04% | 5.54% |

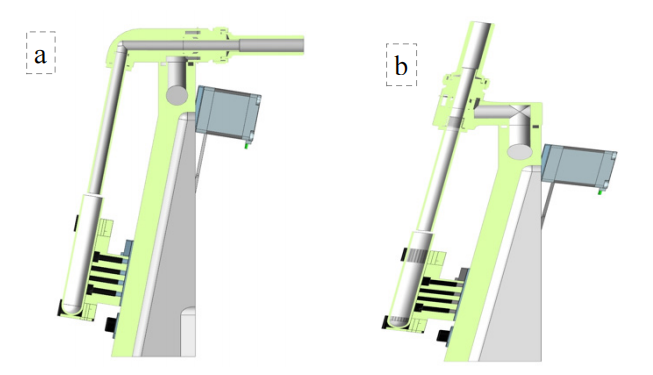

3.4 Dispersion structure

The design and optimization of dry dispersing gas path determine the dispersion state, even for samples with strong adhesion, moisture and agglomeration determine the feasibility of the sample testing process. However, the dispersion structure designed by each manufacturer is not same. Bettersize adopts two different dispersion structures, figure 6 (a) adopts the venturi structure with a feeding direction perpendicular to the direction of the gas path which is easy to cause the risk of clogging a special sample, and the dispersion system needs to be cleaned frequently, affecting the test efficiency, but figure 6 (b) adopts direct negative pressure suction sample method to completely avoid sample blockage, thus ensuring the continuity and reliability of the particle size measurement process.

4. Conclusion

It is crucial to control the particle size and particle size distribution in the coffee grinding process. The laser diffraction particle size analyzer with dry dispersion system conforms to the measurement requirements of coffee powder in terms of the principle and dispersion. During the test, it is necessary to pay attention to the influence of air pressure on the particle size distribution result. The Bettersizer 2600 accurately distinguishes the particle size distribution of coffee powders with different particle sizes in terms of precision and provides good stability for the coffee grinder manufacturer to control product quality, thus effectively analyzing and monitoring the particle size and its distribution of the coffee during the grinding process, ensuring the homogeneity of the product and improving the quality of the coffee. The Bettersizer 2600 also adopts a negative pressure parallel suction dispersion structure to avoid the risk of sample blockage, thus ensuring the continuity and reliability of the particle size measurement process.

About the Author

| Alvin Wang Aftersales Engineer @ Application Research Lab, Bettersize Instruments |

Recommended articles

Rate this article