Laser Diffraction Analysis in Powder Coating Particle Size Distribution Measurement

2020-11-16Application Briefs

Introduction of powder coatings

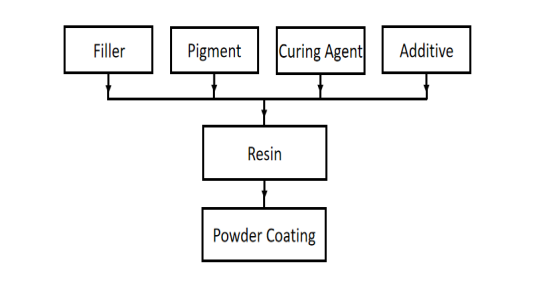

Powder coating is a powder composed of five ingredients solid resin, pigments, fillers, curing agent and additives. It is important that the fillers, pigments, curing agent and additive need to be evenly dispersed in the molten resin before crushing and micronizing the cooled resin into a powder coating. The dispersing medium for solvent based and water-based coatings is solvent or water, but air is used as the dispersing medium for powder coatings. Powder coatings key advantages are that there is no solvent pollution, 100% film formation and low energy consumption. The ingredients that produce the powder coating are shown below in Figure 1. Naturally, laser diffraction analyzer can give a quick, simple and reliable measurement for the powder coating. Therefore, Bettersize laboratory give a comparison test for three different groups of powder coating samples.

Comparison test in different particle size distribution and same type powder coating samples

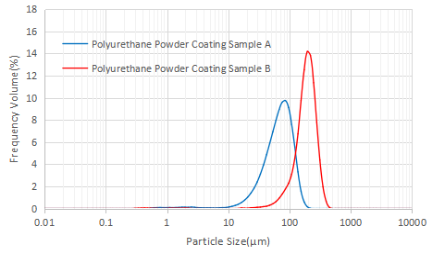

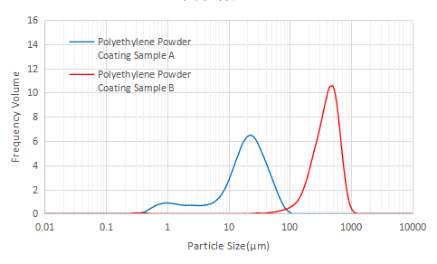

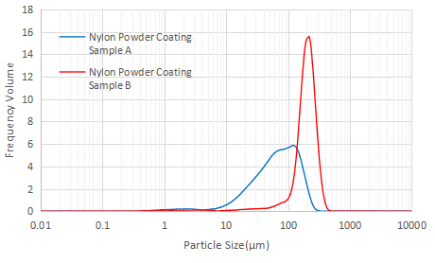

The comparison of particle size distribution of two Polyethylene samples, two Polyurethane samples and two Nylon powder coating samples are shown in Figure 2, Figure 3 and Figure 4. Both different samples of the same type of powder coating show different particle size distributions. All the sample B (red color) powder coating samples have more coarse particles than sample A (blue color), which indicates that sample B builds up a thicker layer during the spraying process than sample A. Also, it can be seen that the polyethylene powder coating sample A and nylon powder coating sample A have broader particle size distributions than sample B, thereby indicating the polyethylene and nylon powder coating sample A provide a better functional property for spraying the workpiece due to their broader particle size distribution..

Figure 3.Comparison of particle size distribution of Polyethylene power coating sample A and sample B by Bettersizer 2600

Figure4.Comparison of particle size distribution of Nylon power coating sample A and sample B by Bettersizer 2600

Conclusion

The particle size of powdered paint coatings affects the performance of spraying. If the particle size of a powdered paint coating is too large, it will exhibit poor flowing properties. If the particle size of a powder coating is too small, it will affect the utilization and recovery rates in the spraying process. Laser diffraction analyzer can easily compare how different two powder coatings are from their particle size distribution. This gained knowledge can be used to recognize and predict their different mechanical properties thus offering satisfactory solutions in real cases for the powdered paint coatings industry.