Exploring Particle Size Distribution in Silicon/Carbon Composite Anode for Lithium-Ion Batteries by Laser Diffraction

2024-03-06Application Note

Silicon/carbon composite anodes are gaining attention in the next generation of lithium-ion batteries due to their ability to harness significant specific capacity. This study focuses on maximizing the energy density of these anodes by monitoring particle size distribution to achieve substantial tapped density and proper specific surface area. The Bettersizer 2600 and BT-80N combination is instrumental in providing precise and highly repeatable measurements for particle size distribution, specifically designed for analyses using organic dispersants.

| Product | Bettersizer 2600 |

| Industry | Battery and Energy |

| Sample | Silicon/Carbon composite anode |

| Measurement Type | Particle size, Particle Size Distribution |

| Measurement Technology | Laser Diffraction |

Jump to a section:

Introduction

With the vigorous development of new energy storage devices (portable devices and electric vehicles) , there is an increasing demand for high energy density in the core component, power batteries. Recent advancements in battery technology, particularly in materials for both cathodes and anodes, have been pivotal in achieving improvements in battery energy density. Notably, silicon-based anodes stand out prominently in this context, offering higher specific capacity and greater sustainability compared to conventional anodes. The utilization of silicon, an abundant and widely available material, holds the potential to reduce dependence on finite natural resources. This positions silicon-based anodes as the optimal choice for the next generation of power batteries, promising a sustainable and efficient future for energy storage solutions.

Silicon/carbon composite materials, a subset of silicon-based anodes, exhibit high specific capacity for new energy batteries. The general structure of this novel anode is shown in Figure 1. Nevertheless, they face challenges such as shortened cycle life and low conductivity. To address these issues, active materials designed with appropriate specific surface area and significant tapped density should be contemplated. In the optimization of silicon/ carbon composite microspheres, critical parameters such as particle size and distribution significantly influence tapped density and specific surface area, thereby affecting cycle life, conductivity, and battery energy density. This application note provides precise inspection over the particle size distribution of one batch of silicon/carbon composite samples, offering valuable insights for anode materials with exceptional uniformity.

![]()

Figure 1. Structural model of silicon/carbon micro-sized anodes

Measurement design

When measuring the particle size of anode material using a laser particle size analyzer, the selection of an appropriate dispersing solvent is important so as to prevent particle aggregation and ensure more uniform dispersion in the liquid. Generally, a good dispersant for particle size analysis should not react with samples, provide consistent dispersion, and contribute to suspension stability, etc. Isopropanol is a commonly used organic solvent on silicon-based sample because that its low surface tension contributes to the even dispersion of particles. BT-80N anti-corrosive wet dispersion unit is designed for particle size measurements with organic solvents as the media, which is suitable for common organic solvents, for example:

Table 1. Common organic solvents used in BT-80N

|

Ethanol |

Methanol |

Isopropanol |

Ether |

|

Toluene |

Xylene |

Dichloromethane |

Octane |

|

Ethyl acetate |

Acetone |

Methyl oleate |

NMP solvents |

Taking into account the requirements of the sample testing and dispersant, this studay utilizes the Bettersizer 2600 along with the BT-80N to ensure accurate and reliable particle size measurements. The materials involved in this experiment include five types of silicon/carbon composite anodes dispersed in isopropanol.

Bettersizer 2600 with BT-80N

Bettersizer 2600 with BT-80N

Result and Discussion

Particle Size Distribution Analysis

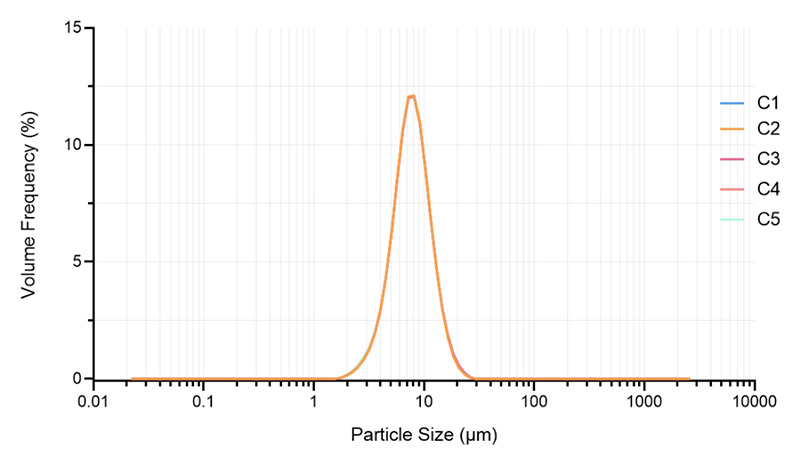

Particle size and distribution of silicon-based anode samples are measured using the Bettersizer 2600 and BT80N. Figure 2 displays the particle size distribution for the 5 samples, while Table 2 presents the corresponding typical size values. The median size value (D50) of the five samples is 5.808 μm, 6.130 μm, 7.228 μm, 11.010 μm and 26.690 μm, respectively. The D50 of a particle size distribution refers to the particle size corresponding to the cumulative frequency of 50%, which is a typical parameter to evaluate the charge-discharge process, cycling life and stability of the anode material.

![]()

Figure 2. Particle size distribution of silicon/carbon anode

Table 2. Typical particle size values of silicon/carbon anode

|

Sample |

D10 (μm) |

D50 (μm) |

D90 (μm) |

Span |

|

A |

2.417 |

5.808 |

10.630 |

1.409 |

|

B |

2.594 |

6.130 |

10.820 |

1.343 |

|

C |

4.239 |

7.228 |

11.920 |

1.063 |

|

D |

5.452 |

11.010 |

19.960 |

1.318 |

|

E |

12.130 |

26.690 |

44.750 |

1.221 |

As mentioned earlier, the specific surface area is related to the cycle life of lithium-ion battery, and essentially, the specific surface area is inversely proportional to particle size. According to the results, the Bettersizer 2600 excels in accurately monitoring the particle size and distribution of these micro-sized anodes prepared under the same process. These measurements not only confirm its exceptional resolution capability but also validate its effectiveness in optimizing the specific surface area and extending cycle life.

Moreover, uneven particle size distribution in silicon/carbon composite anodes can cause insufficient tapped density and thereby low energy density. Therefore, focusing on relatively uniform particle size distribution is crucial for silicon-based anodes. According to the analysis, sample C demonstrates the narrowest particle size distribution, suggesting the most uniform particle distribution among these five samples.

Repeatability Assessment

In the repeatability assessment of sample C, Figure 3 illustrates the consistent outcomes obtained from multiple measurements conducted by the Bettersizer 2600 equipped with BT-80N. The repeatability values for D10, D50, and D90, namely 0.11%, 0.03%, and 0.09% respectively, fall significantly below the stipulated limits outlined in ISO 13320. Hence, utilizing the Bettersizer 2600 for the particle size distribution analysis of silicon-based anodes shows remarkable repeatability.

Figure 3. Repeatability test of sample C

Conclusion

In order to promote the advantages of silicon/carbon composite and enhance its energy density, it is essential to focus on the particle size and distribution of this material. The demonstration of Bettersizer 2600, coupled with BT80N, highlights its effectiveness in delivering accurate and consistent results for micro-sized anode materials. Based on this study, the D50 of the five samples is 5.808 μm, 6.130 μm, 7.228 μm, 11.010 μm and 26.690 μm, respectively. Furthermore, the repeatability values of sample C are well below the limitations specified in ISO 13320. This underscores its advanced capabilities in measuring particle size with organic solvents, providing valuable insights into the optimization of silicon-based anodes for enhanced energy density solutions and battery performance.

About the Author

|

Feiqing Shen Application Engineer @ Bettersize Instruments |

|

Unlock the secrets to high-performance Lithium-ion batteries with the collection of SEVEN battery application notes. (pdf) |

|

Rate this article