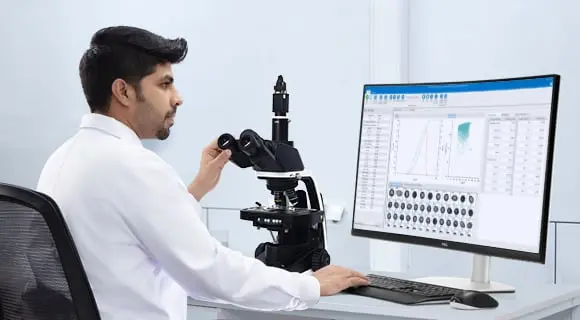

BeVision S1は、0.3〜4,500μmの範囲における粒子径および形状を簡便かつ高精度に測定・分析するための優れたソリューションを提供します。操作が簡単でありながら、信頼性と精度を兼ね備えており、さまざまな分析ニーズに対応可能です。BeVisionソフトウェアは、34種類の粒子径および形状パラメータを提供し、データを総合的に整理して粒子の完全な検証をサポートします。これにより、粒子の詳細な特性評価が可能となり、分析結果を直感的に理解することができます。さらに、BeVision S1は、単独の粒子サイズおよび形状分析装置としてだけでなく、レーザー回折式粒子解析装置と組み合わせて使用することも可能です。これにより、補助的な分析や検証を行い、信頼性の高いデータを提供します。

機能と利点

- ● 測定範囲: 0.3 ~ 4,500 μm

- ● 乾式および湿式測定対応

- ● 34種類の粒子径および形状パラメータを提供

- ● 特定の用途にオプション顕微鏡を選択可能

- ● 強力なソフトウェアで作業の効率化

- ● カスタマイズ可能なレポート機能

- ● ISO 9276-6準拠の測定結果