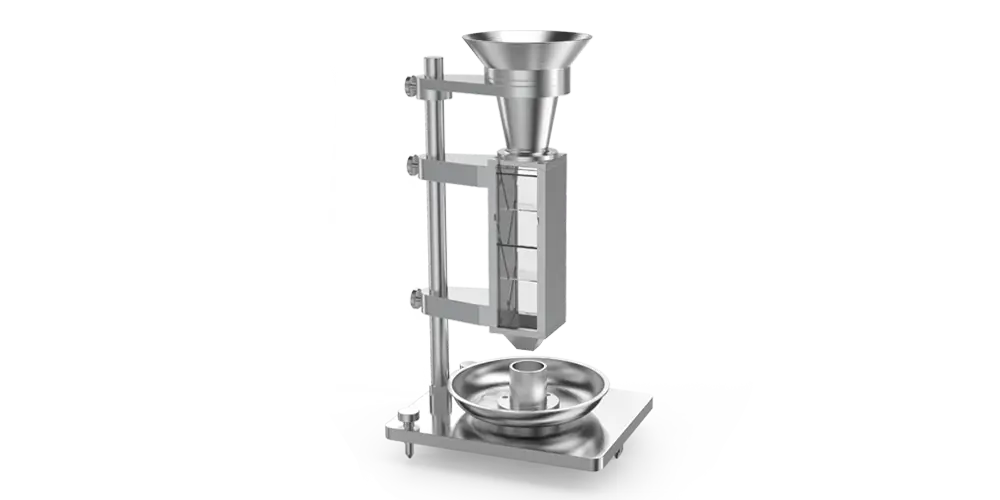

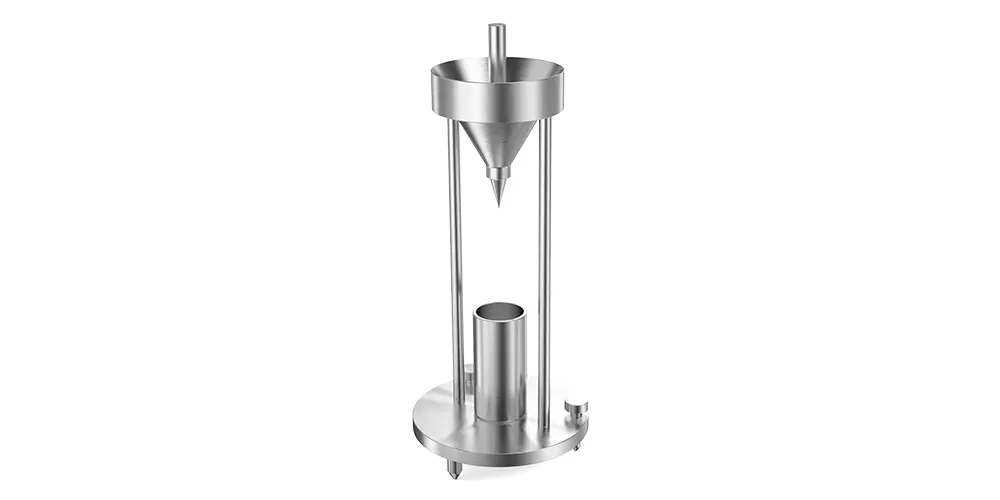

PowderPro A1

The PowderPro A1 integrates many state-of-the-art technologies such as intelligent control via Wi-Fi , image processing technology, and 3D electromagnetic vibration technology. It can measure the physical properties of powders in a fast, simple, and accurate way. As an intelligent powder characteristics tester, it is an essential instrument to help you understand and research powder materials.

Features and Benefits

- ● Compact design

- ● Multiple controls

- ● Convenient data output

- ● Intelligent data transmission

- ● Automated control technology

- ● Automated imaging technology