Particle Size Analysis of Skimmed and Full-Fat Milk Powder

2020-11-26Application Briefs

Milk powder, as an important raw material in the field of food processing, is widely used in the production of drinks, coffee, cakes, yogurt, recovery milk, sauces, etc. As people’s living standards continuously improve, their consumption and requirements of dairy products, such as the flavor profiles and sensory characteristics, also gradually increase. As we know, milk powder composition and physical and sensory properties of milk powder are easily affected by production, packaging, transportation, storage, and other processes. For example, different manufacturing parameters in the production process of milk powder, such as homogenization, spray drying, and sieving, are likely to affect the particle size distribution of the milk powder. Thus, it is essential for milk powder manufacturers and relevant equipment manufacturers to check the size distribution of milk powder during the production process in real-time.

Generally, milk powder sizing methods include microscopy, sedimentation, sieving, image analysis, and light scattering. In particular, laser diffraction is widely applied by milk powder manufacturers, because of its advantages includes ease of use, high accuracy, precision, etc.

In this study, the Bettersizer 2600 laser diffraction particle size analyzer, with the dry dispersion module, was used to determine the particle size distribution of milk powders. The Bettersizer 2600 adopts the combination technology of Fourier and Inverse Fourier design to simultaneously detect the scattered light signals of the sample in the forward, lateral and backward direction. Meanwhile, an inclined sample cell is utilized in order to diminish the effect of total internal reflection and have a wider measuring range. This innovative technology provides high resolution and accuracy. Therefore, the Bettersizer 2600 is a useful sizing tool especially for investigating the size distribution of fat and casein particles, as well as their interaction.

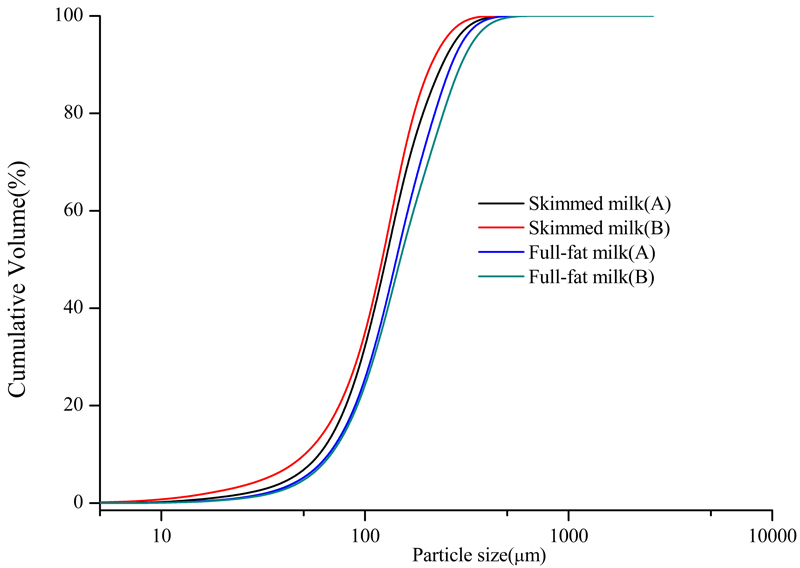

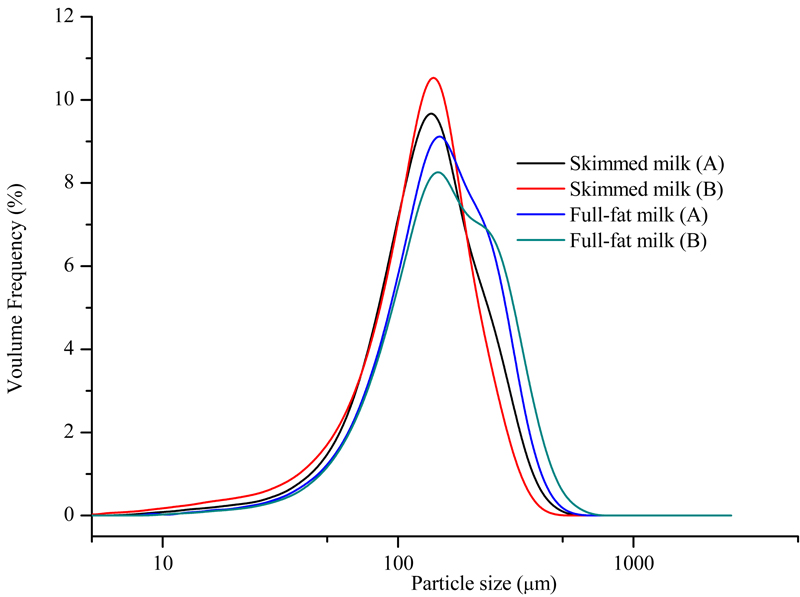

As shown in Figure 1, the average particle size of full-fat milk powder is significantly larger than that of the skimmed milk powder. Besides, Brand A’s skimmed milk powder had a larger average particle size than Brand B. However, the full-fat milk powders are larger in particle size from Brand B instead of Brand A.

Furthermore, it can be clearly observed from Figure 1 and Figure 2 that the average particle size of skimmed milk powder of Brand A is larger than that of Brand B, while the average particle size of full-fat milk powder of Brand A is smaller than that of Brand B. Reason to this discrepancy is the diverse parameters setting of different brands when producing the same type of milk powder. For example, different settings of powder spray drying process (air inlet and outlet temperatures, nozzle air pressure, rotational speed, etc.) might impact the particle size of milk powder. In addition, homogeneous mixing speed and pressure also contribute to the particle size distribution of the milk powder. If the homogenous speed is low or the homogeneous time is short, some overly large fat particles might not be broken, leading to the larger powder particle size.

Conclusion

In the production and application process of milk powder, the particle size of milk powder directly affects its final taste, sensory properties, and quality characteristics. The Bettersizer 2600 can be used by milk powder manufacturers or relevant equipment manufacturers to accurately monitor the size changes of milk powder during production, packaging, storage, and application process, as well as to better understand the relationship between dairy product formulation and quality.