Particle Size Measurement and Agglomerates Detection of Ceramic Materials During Production Process

2022-04-18Application Note

Accurate measurement of ceramic powders is crucial in the ceramic manufacturing. The Bettersizer S3 Plus has been proven to accurately measure the particle size and size distribution, and effectively monitor the agglomeration existing in ceramic powder materials. Therefore, the Bettersizer S3 Plus is a valuable tool to display both particle size and shape results. With the assistance of the Bettersizer S3 Plus, manufacturers are able to produce high performance ceramic products.

| Product | Bettersizer S3 Plus |

| Industry | Ceramics |

| Sample | Aluminum Oxide |

| Measurement Type | Particle size, Particle Shape |

| Measurement Technology | Laser Diffraction, Dynamic Image Analysis |

Jump to a section:

- Introduction

- Result

- Fine Particles

- Particle size distribution

- Agglomeration

- Conclusion

- Reference

Introduction

The strength of modern ceramic products is usually determined by the powder characteristics in four phases: powder pretreatment, dispersing and mixing, molding, and sintering. To reach the optimal strength of the final products, particle size is the primary factor to be considered from the powder pretreatment stage. This is because fine particles with large surface and molecular gravity are more likely to aggregate than coarse particles. In addition, agglomeration dramatically reduces sintering efficiency and increases the probability of ceramic component failure. Therefore, it is important to monitor and control the aggregation in the fine powder materials throughout the whole production process in order to improve the strength of ceramic products.

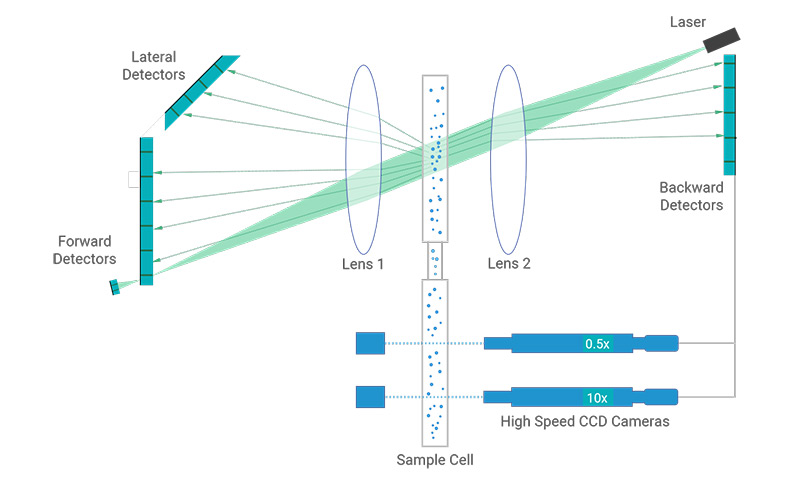

The Bettersizer S3 Plus uses the patented DLOI System (Dual Lenses and Oblique Incidence System) technology to ensure the measurements of ceramic fine powders. Meanwhile, the integrated high-resolution CCD camera allows manufacturers to observe agglomeration in real time during particle size measurements. In this application note, the particle size, size distribution, and aggregates of the aluminium oxide powder will be analyzed to help manufacturers achieve a better strength of ceramic products.

Figure 1. The Bettersizer S3 Plus optical system

Result

Fine Particles

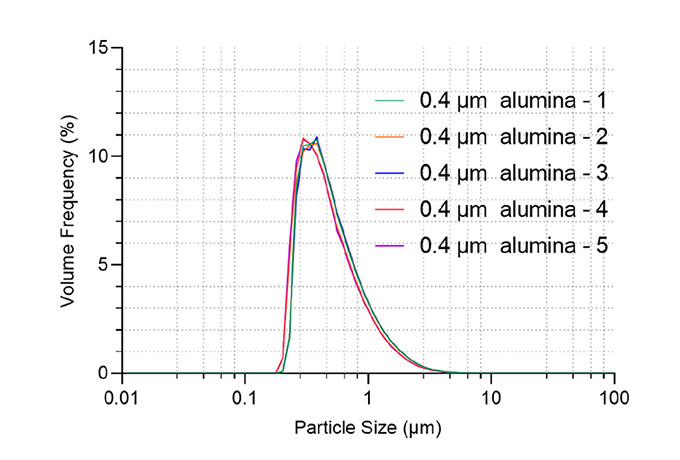

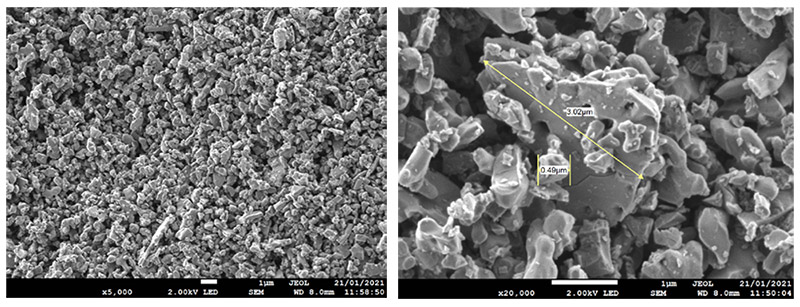

Accurate measurement of fine particles in ceramic manufacturing is necessary. The certified 0.4 μm sample was purchesed from Aladdin Chemical Supplier. According to the results listed in Table 1 and Figure 2, the average of D50 is 0.396 μm, which is close to SEM results of the sample in Figure 3. The repeatability of D50 is 0.39%, which ensures the reliability of the analysis and is fully compliant with the ISO 13320 standard[1].

| Sample | D10 (μm) | D50 (μm) | D90 (μm) |

| 0.4μm alumina-1 | 0.241 | 0.395 | 0.962 |

| 0.4μm alumina-2 | 0.24 | 0.396 | 0.962 |

| 0.4μm alumina-3 | 0.243 | 0.398 | 0.967 |

| 0.4μm alumina-4 | 0.243 | 0.396 | 0.966 |

| 0.4μm alumina-5 | 0.24 | 0.392 | 0.957 |

| Repeatability | 0.63% | 0.55% | 0.45% |

Table 1. Typical size values of alumina sample

Figure 2. Particle size distribution and repeatability of 0.4 μm alumina sample

Figure 3. SEM result of aluminium oxide sample

Particle Size Distribution

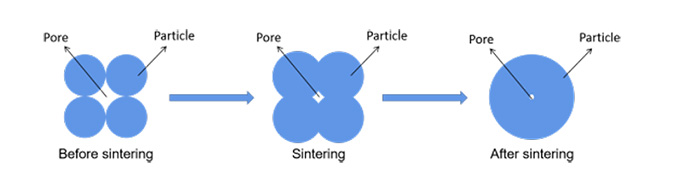

The sintering is to compact powders into a dense product (also known as green body). During the stage, the powders are heated just below the melting point of the raw material. The shrinkage occurs in the green body, and bonds form between particles. As a result, the space decreases and strength of the green body increases. Figure 4 explains the mechanism during the sintering process.

Figure 4. Mechanism of sintering

The particle size and size distribution have great effects on sintering rates. The sintering driven force decreases with the increasing particle size, so large powders are not able to bond efficiently [2, 3]. In other words, the pore size cannot efficiently decrease. One solution to reduce the impacts of large pores is to mix fine ceramic powders with large particles, and therefore small particles can fill the pores during sintering [4].

Figure 5. Particle size distribution of aluminium oxide sample

| Sample | D10 (μm) | D50 (μm) | D90 (μm) |

| Aluminium Oxide Sample | 5.333 | 11.49 | 20.50 |

Table 2. Typical particle values of aluminium oxide sample

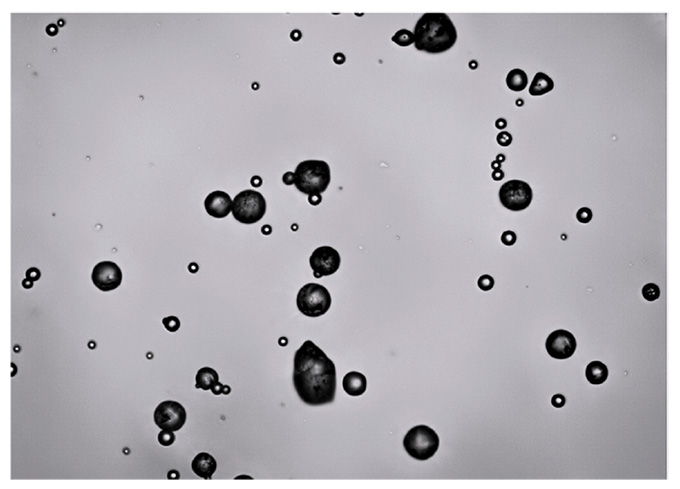

Figure 6. Particle image of aluminium oxide powder

The alumina powder sample from a ceramic manufacturing company. The median size is 11.49 μm, but the particles distributed from 3.633 μm to 23.41 μm as shown in Figure 5 and Table 2. The sample contains some tiny particles which can be observed in Figure 6. Consequently, fine particles in the sample could fill into the pores, and has less probability to build large pores during sintering.

Agglomeration

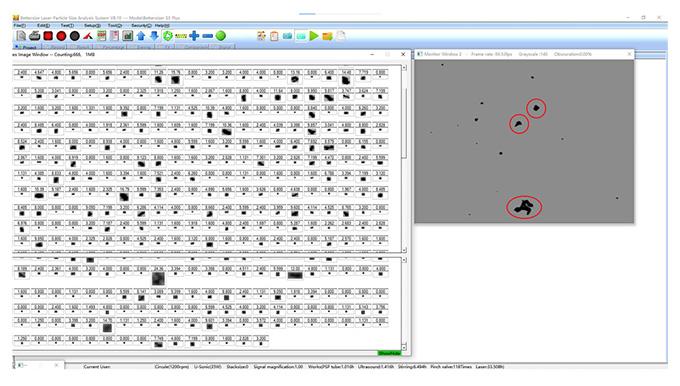

In ceramic industry, not only particle size and size distribution dominate the final strength, the agglomerates or oversized particles have strong impacts on it. The real-time analysis window could display the aggregated particles, as shown in Figure 7.

Figure 7. Observed aggregates in real-time display window

The agglomeration will cause a decline of final products’ strength, since agglomeration significantly decreases the density of green body [4].

Conclusion

Accurate measurement of ceramic powders is crucial in the ceramic manufacturing. The Bettersizer S3 Plus has been proven to accurately measure the particle size and size distribution, and effectively monitor the agglomeration existing in ceramic powder materials. Therefore, the Bettersizer S3 Plus is a valuable tool to display both particle size and shape results. With the assistance of the Bettersizer S3 Plus, manufacturers are able to produce high performance ceramic products.

Reference

[1] ISO 13320 (2009) Particle size analysis – Laser diffraction methods.

[2] Peelen, J. G. J. (1977). Alumina: sintering and optical properties. Technische Hogeschool Eindhoven.

[3] W.D. Kingery et al (1976). Introduction to Ceramics, 2nd Edition. John Wiley & Sons.

[4] Kumar, A. (2013). Practical classes " Ceramics & Colloids “: TP 3 Sintering 1 TP 3-Ceramics: Sintering and Microstructure Responsable

About the Author

|

Xiurong Qiu Application Engineer @ Bettersize Instruments |

Rate this article