Application of Laser Particle Size Analyzer in Ceramic Powders

2021-04-06Application Note

Accurate measurement of the particle size distribution of ceramic powders is extremely necessary in the production of modern ceramic components. It has been proved that the particle size and dispersibility of a ceramic powder can be determined by the Bettersizer 2600, and the test results have a high repeatability.

| Product | Bettersizer 2600 |

| Industry | Ceramics |

| Sample | Ceramic powder |

| Measurement Type | Particle size |

| Measurement Technology | Laser Diffraction |

Jump to a section:

Introduction

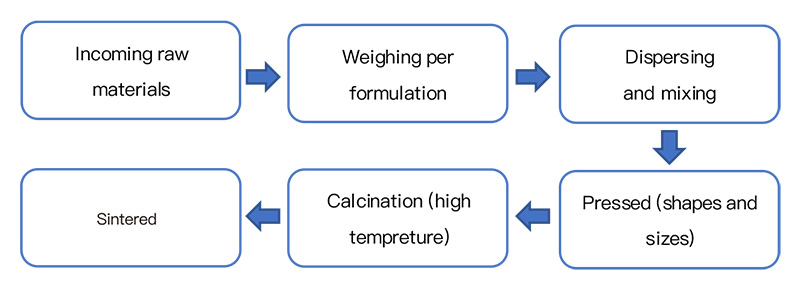

The production of modern ceramic components can be generally divided into two distinct processing stages. First, the ceramic powder is evenly dispersed in a liquid to specific proportions, and then compacted into a pre-determined optimal shape and size that is called the "green body". A green body is the name given to an object whose main constituent is weakly bound clay material, usually in the form of a bonded powder or plates before it has been sintered. The green body is heated to just below the melting point of the ceramic materials and sintering occurs at this temperature, causing the particles in the green body to become bonded together.

The production process of ceramic components is shown in Figure 1. The production of ceramic components is highly dependent on the physical properties of the ceramic powders and how they disperse during formation. Ceramic powders can easily agglomerate in the dispersing process, and the uniformity of the powdered particles can be poor, which ultimately lead to a lower performance in ceramic materials such as piezoelectric products. To alleviate this problem, the measurement of the size of the ceramic powder particles during the production of ceramic components is essential. Particularly, particle size analysis can help the manufacturer to determine the optimum time and temperature required for the green body to reach a predetermined optimal desired density in the sintering process. Generally, a ceramic powder with a proportion of smaller particles can reduce the sintering time of the green body due to it having a larger surface area. Therefore, the particle size distribution measurement of ceramic powder is one of the most critical parameters to control in the production process of ceramic components.

Figure 1. The manufacturing process of ceramic products

In this application note, the Bettersizer 2600 laser diffraction particle size analyzer, with the wet dispersion module, was used to determine the particle size distribution of some ceramic powders. The Bettersizer 2600 adopts the combination of Fourier and Inverse Fourier design to simultaneously detect the scattered light signals of the sample in the forward, lateral and backward directions. In addition, an inclined sample cell is utilized to diminish the effect of total internal reflections and thus attain a wider measuring range, high resolution and accuracy. In this and many other applications, the Bettersizer 2600 is a useful particle sizing tool, especially for investigating the size distribution of many ceramic materials, as well as their interactions.

Measuring the particle size distribution of ceramic powders

Many different techniques have been used to measure the particle size distribution of ceramic powders. Leading these technologies, the Bettersizer 2600 laser particle size analyzer offers unique advantages due to its ease of use and fast operation. The dynamic measuring range covered by the Bettersizer 2600 is extremely broad, allowing the ceramic powders and aggregates to be easily detected in a single measurement at the same time with a high repeatability. Three ceramic samples provided by a manufacturer were measured and the test results are as follows.

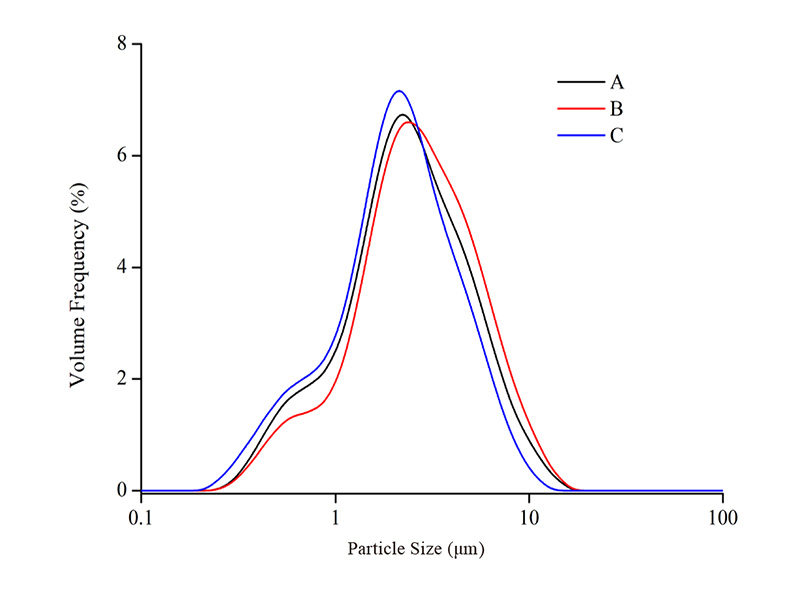

As can be seen from Figure 2, the test results of samples A, B and C show a broad distribution with a sub-micron inflection in each case. A broad particle size distribution often indicates low powder homogeneity. Small but important differences in the distribution may be related to the differences in the processing techniques. The size and distribution of the ceramic material particles prior to the sintering of the green body must be controlled no matter what processing technique is used. Usually, there is a direct relationship between the particle size of ceramic powder and the pore size observed in the green body prior to sintering. In particular, large ceramic powders with low surface area tend to combine ineffectively. This can lead to the formation of large pores which persist during sintering leading to the possibility of unqualified ceramic products [1]. However, the formation of large pores can be controlled using uniform powders with smaller particle sizes or by using a polydisperse particle size distribution where the fine particles within the powder fill in the voids between the larger particles.

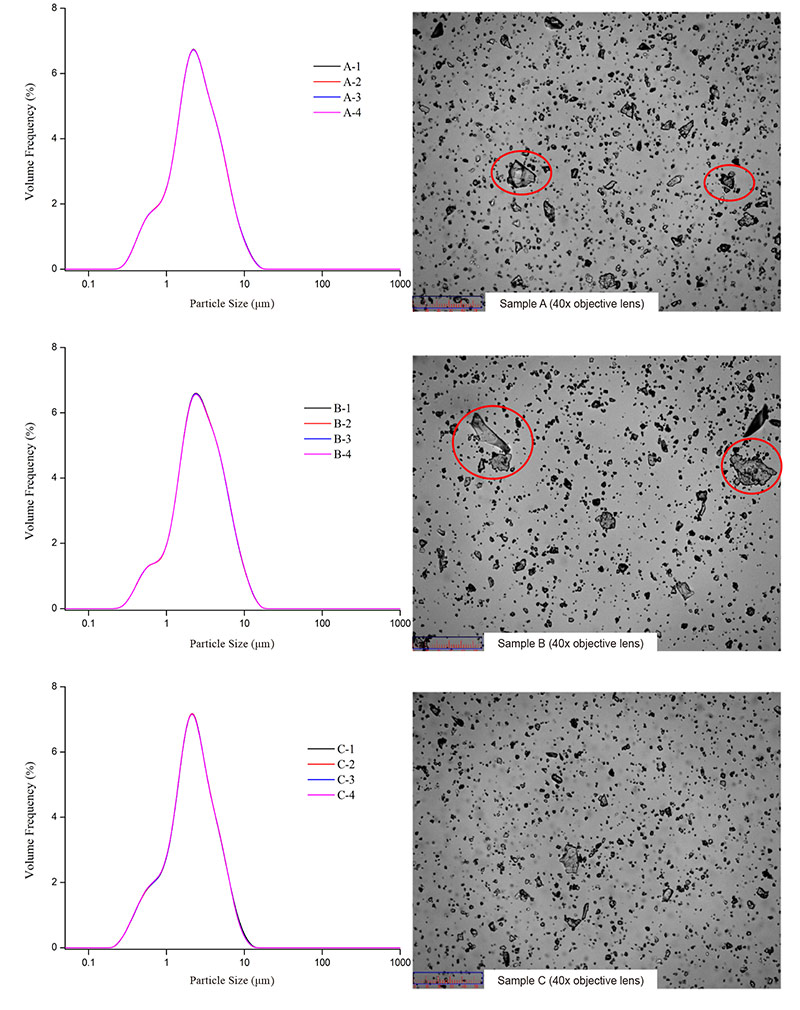

Furthermore, as can be seen from Figure 2, sample A and sample B have more coarse particles than sample C. It is of particular note that coarser particles greater than 10 µm appear in both of sample A and sample B, which is an indication that the particle uniformity of sample A and sample B is poorer than sample C. This is verified by the optical microscope images in Figure 3, where the distribution of coarse particle aggregates is clearly observed for sample A and sample B but not seen in sample C. This can lead to differences in the physical properties of the powdered ceramic material itself or influence the dispersibility of the ceramic mixed materials even before the formation of the green body. And large pores will be created in the parts of sample A and sample B, which are detrimental to the sintering process.

So, for this application the manufacturers need to make sure that the particle size range is not too broad and that the packing factor is optimized by having the appropriate ratio of coarse to fine particles. In particular, no oversized agglomerates should be present.

Figure 2. Particle size distribution of samples A, B and C

Figure 3. Particle size distribution and image analysis of sample A, B and C

| Typical value | Repeatability (%) | ||

| Sample A | Sample B | Sample C | |

| D10 | 0.31 | 0.11 | 0.13 |

| D50 | 0.86 | 0.15 | 0.09 |

| D90 | 0.74 | 0.42 | 0.07 |

Table 1. Repeatability analysis of the samples

All these factors determine if the sample A, B and C are suitable for producing ceramics or not. To confirm these results, a static imaging analysis system was used [2]. The images captured in Figure 3 clearly show the presence of aggregates in samples A and B.

In addition, it can be seen from Figure 3 that the multiple measurements of the 3 ceramic materials by the Bettersizer 2600 indicate good repeatability. This is best shown in Table 1. The repeatability values are far below the requirements of ISO 13320 [2]. Therefore, the confidence in the results of these ceramic powders is high by using the Bettersizer 2600.

Conclusion

Accurate measurement of the particle size distribution of ceramic powders is extremely necessary in the production of modern ceramic components. It has been proved that the particle size and dispersibility of a ceramic powder can be determined by the Bettersizer 2600, and the test results have a high repeatability. This high-speed accurate analysis showed less coarse agglomerates in sample C, compared to samples A and B, both of whom could be predicted to have a lower homogeneity. Thus, a sizing tool of this kind can help in the development and quality control of ceramic powders, thus reducing the production costs.

Reference

[1] W.D. Kingery et al., Introduction to Ceramics, 2nd Edition, 1976, John Wiley & Sons.

[2] ISO 13320 (2009) Particle size analysis – Laser diffraction methods.

About the Author

|

Fangfang Zhang Application Engineer @ Bettersize Instruments |

Rate this article